Low-VOC (volatile organic compound) high-strength preservative-containing oil-resistant paint process system, process and formula

A process system, high solid content technology, applied in coatings, mixer accessories, chemical instruments and methods, etc., can solve the problems of insufficient fineness and poor dispersion effect, and achieve the effect of simple structure and uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

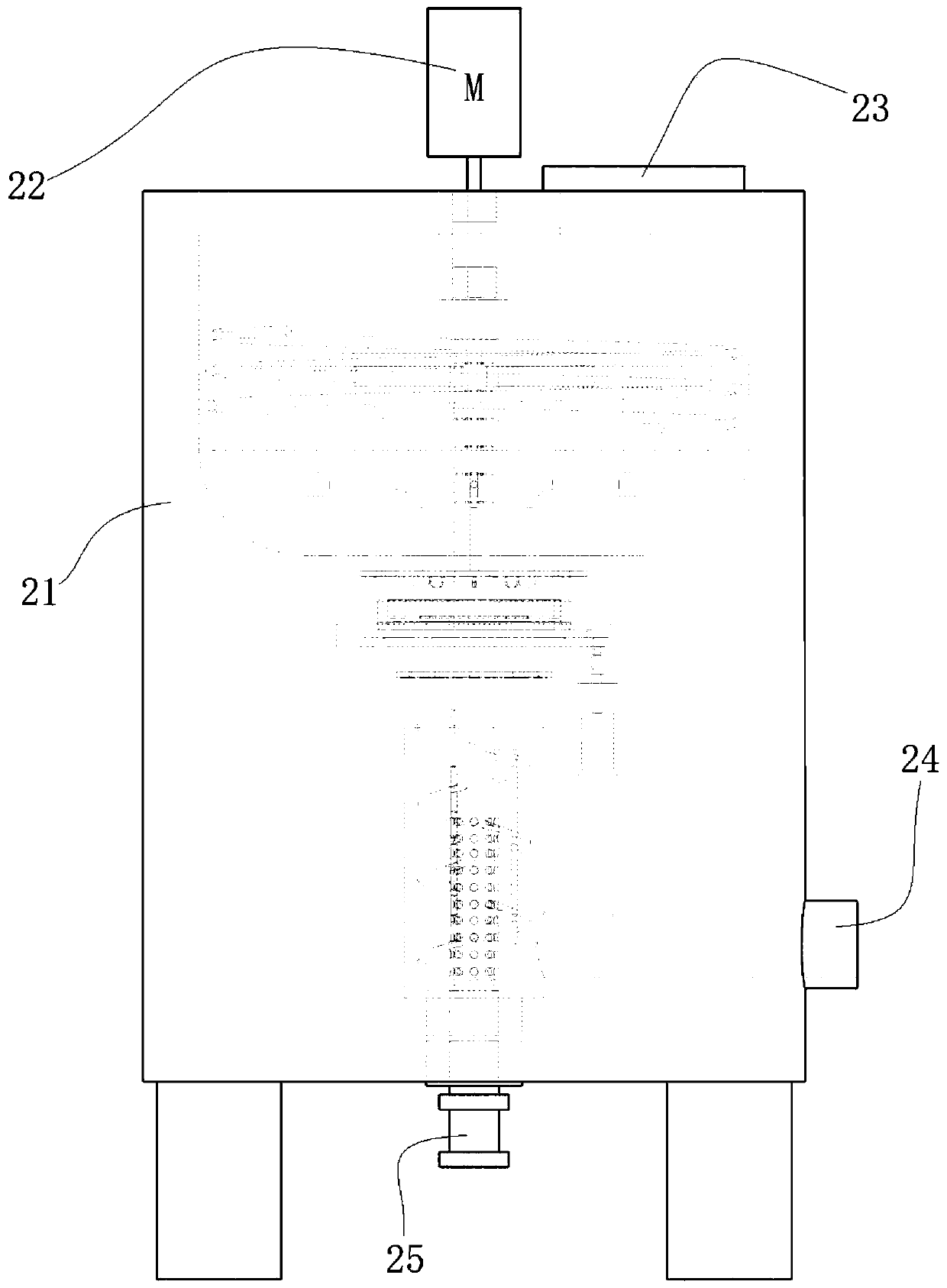

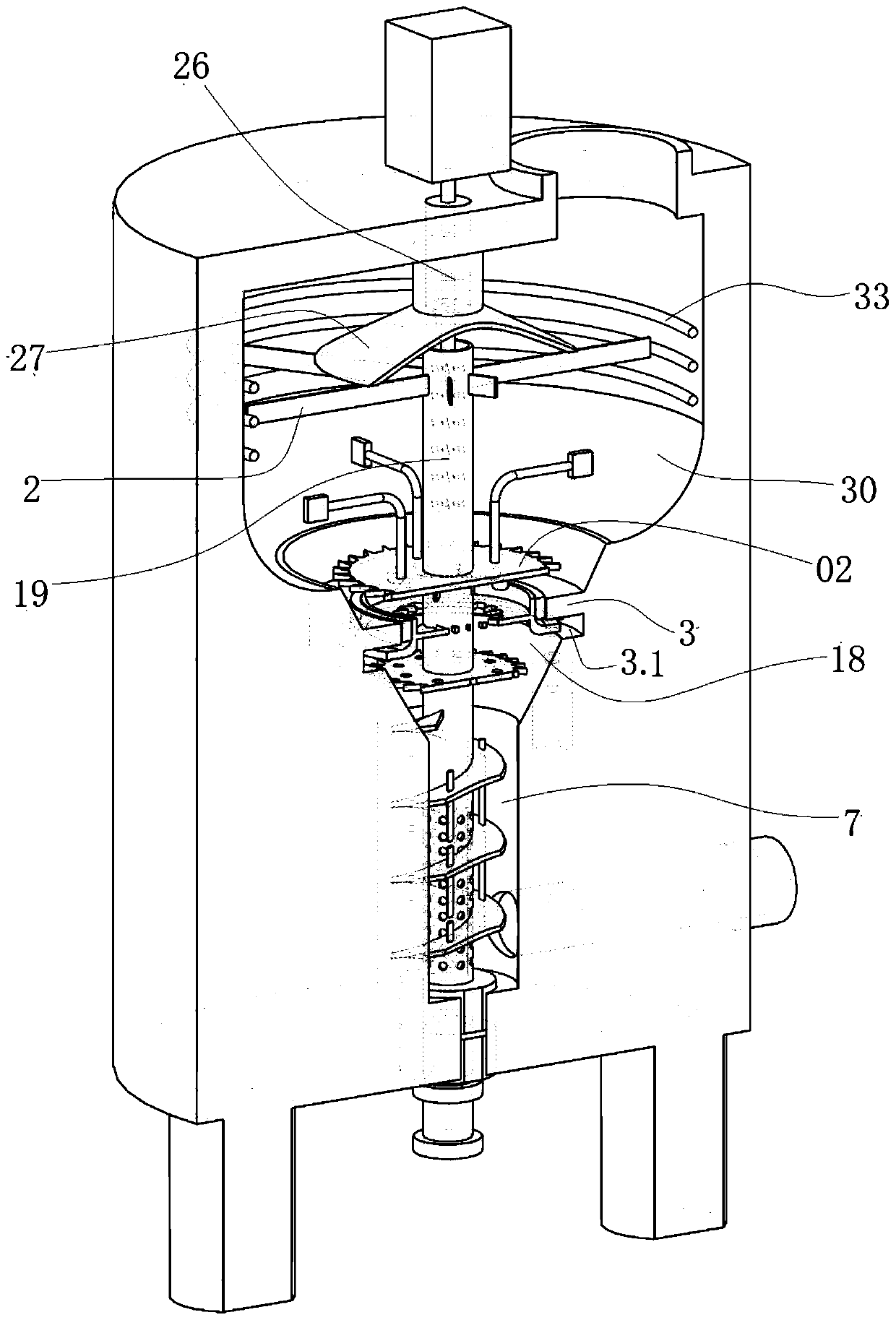

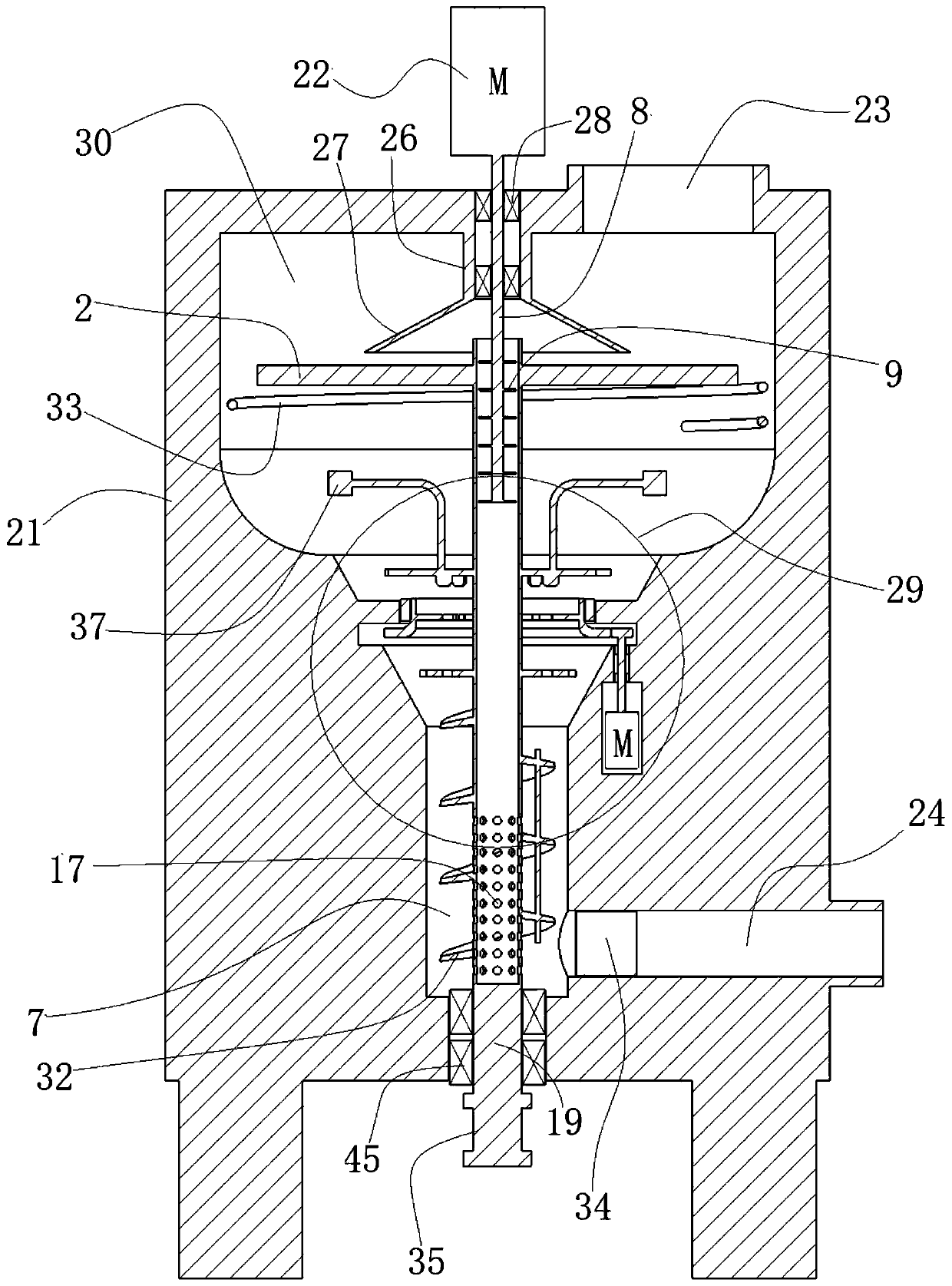

[0027] as attached Figures 1 to 6 The shown low-VOC high-solid anti-corrosion and oil-resistant paint process system includes a vertical paint dispersion tank 21, and the upper concentric center in the paint dispersion tank 21 is provided with a rough mixing chamber 30. The lower part is coaxially provided with a columnar conveying chamber 7, and the middle part of the paint dispersing tank 21 is coaxially provided with a dispersing cone chamber 18 that is thicker at the top and thinner at the bottom, and the upper end of the dispersing cone chamber 18 communicates with the A rough mixing chamber 30, the lower end of the dispersing cone chamber 18 is coaxially connected to the upper end of the transfer chamber 7;

[0028] The top side of the rough mixing chamber 30 is provided with a feeding port 23, and the bottom side of the transfer chamber 7 is connected with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com