PVC (Polyvinyl Chloride) adhesive tape and preparation method thereof

A tape and formula technology, applied in the direction of adhesives, film/flake adhesives, coatings, etc., can solve the problems of wasting energy and time, affecting the performance of tapes, reducing waste and avoiding uneven longitudinal and lateral expansion. , the effect of reducing processing time and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

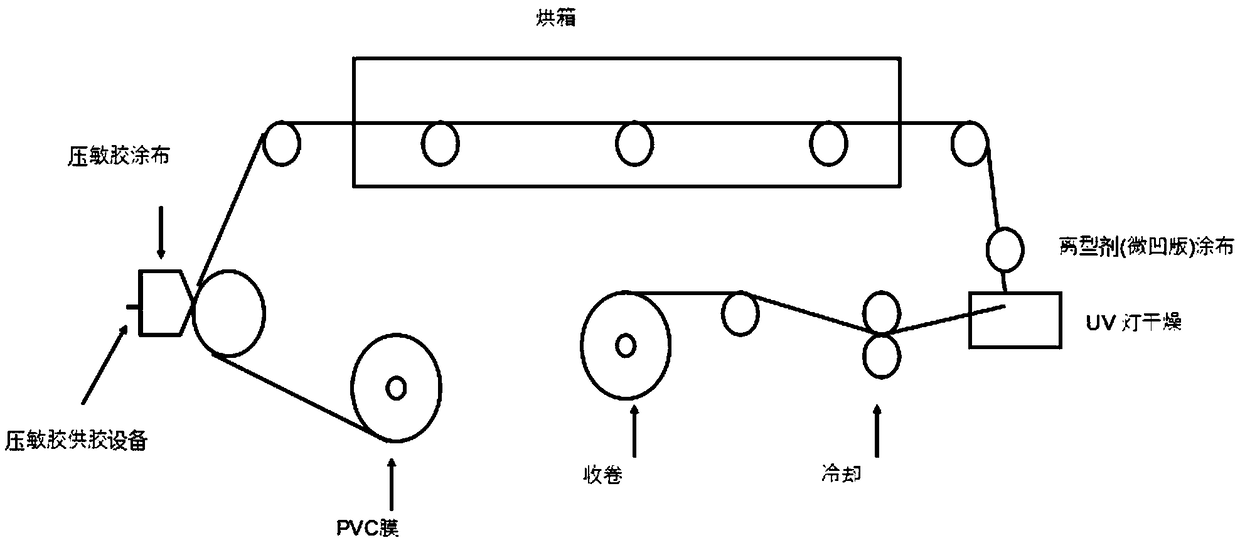

[0051] A kind of preparation method of PVC adhesive tape, its technological process is as image 3 shown, including steps:

[0052] (a) Coating acrylic pressure-sensitive adhesive on one side of the PVC film.

[0053] (b) coating the other side of the PVC film with a release agent that can be hardened by ultraviolet radiation;

[0054] The release agent formula is:

[0055] Silicone oil C715: 25wt%;

[0056] Silicone oil RC722: 70wt%;

[0057] Silicone oil A18: 2wt%;

[0058] The mixture of silicone oil and photoinitiator CD9051: 3wt%.

Embodiment 2

[0062] With reference to Example 1, the difference is that the release agent formula is:

[0063] Silicone oil C715: 40wt%;

[0064] Silicone oil RC722: 50wt%;

[0065] Silicone oil A18: 5wt%;

[0066] The mixture of silicone oil and photoinitiator CD905 1:5wt%.

Embodiment 3

[0068] With reference to Example 1, the difference is that the release agent formula is:

[0069] Silicone oil C715: 29wt%;

[0070] Silicone oil RC722: 69wt%;

[0071] Silicone oil A18: 2wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com