A paint dipping device for built-in motor coils of household appliances

A technology for household appliances and dipping, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., and can solve problems such as the influence of coil processing and use, a large amount of paint remaining, and the poor effect of coil dipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

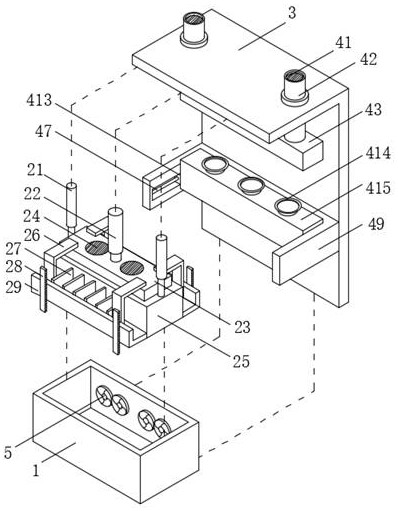

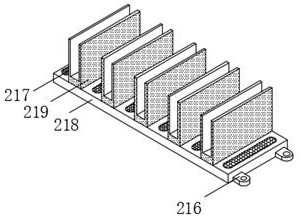

[0046] The specific implementation method is: by setting the paint dipping mechanism 2, wherein the first electric push rod 21 can drive the paint dipping box 25 to move down when it works, at this time, the paint dipping box 25 can drive the coil to move down to dip the paint, and the paint liquid passes through the dipping paint. The paint hole 217 enters into the paint dipping box 25. During the paint dipping process, the second electric push rod 22 can be controlled to extend or shrink. When the second electric push rod 22 is stretched, it can drive the pressing plate 23 to move down. The plate 214 drives the second inserting plate 215 to move down, and the second inserting plate 215 can squeeze the coil placed in the U-shaped groove. When the pressing plate 23 moves down, it will drive the first L-shaped plate 26 to move down, and the first L-shaped plate 26 will move downward. The shaped plate 26 can drive the hemispherical block 213 to squeeze the triangular block 212. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com