Lost foam slurry dipping device for new energy foundry

A foundry and new energy technology, which is applied in the field of lost foam slurry dipping devices in new energy foundries, can solve the problems of affecting the uniformity of slurry, affecting the casting purity, and occupying the position of the model, so as to achieve improved effect, convenient operation, and device design. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

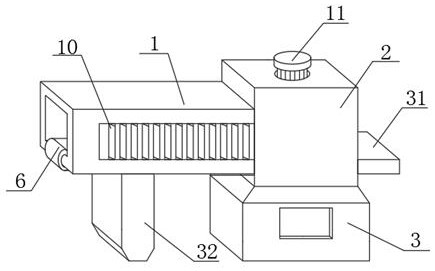

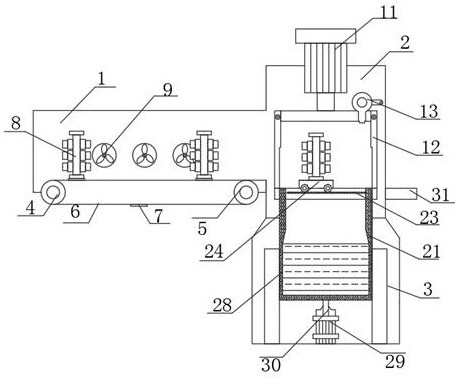

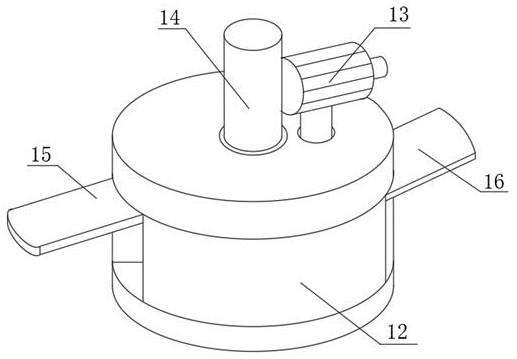

[0025] like Figure 1-5 As shown, a new energy casting factory disappears the mold cladding device, including dust-proof boxes 1, the working case 2 and the lower working case 3, the bottom of the dust box 1 is provided with the driven wheel 4, the active wheel 5 and the belt 6, The driven wheel 4, and the drive wheel 5 are connected by the belt 6, and the belt 6 is fixed to the belt plate 7, and the placing plate 7 is provided with a tree group molding 8. On one side of the dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com