One-step-method yarn doubling winder

A winder and footwork technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems affecting the comprehensive benefit of production enterprises, large yarn wear, low work efficiency, etc. Economic and social benefits, small tension difference, and the effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

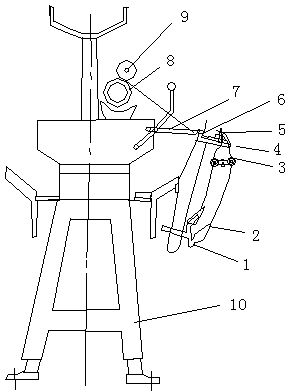

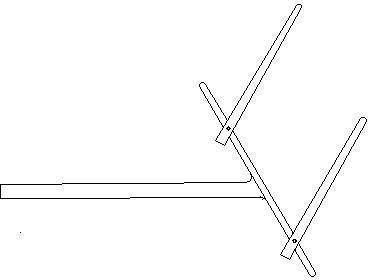

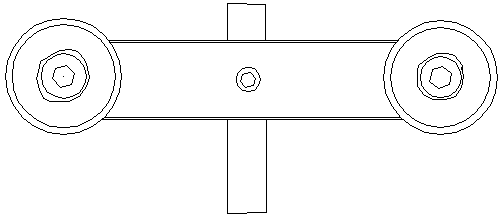

[0014] Such as figure 1 , figure 2 As shown, the one-step doubling and winding machine includes a frame 10 and several groups of doubling and winding mechanisms arranged on the frame, and each doubling and bobbin mechanism includes bobbins inserted on the frame from bottom to top. device, yarn guide device and winding device, the bobbin yarn insertion device is a new type of yarn insertion spindle with two or more spindles ( figure 2 It is a schematic diagram of a new type of spindle with two spindles, and it can also be a new type of spindle with more than two spindles). The yarn guiding device consists of a sub-spindle disc spring tensioner 3 ( image 3 ), (two or more spindles correspond to the inserted spindles, and spring-type adjustable tension disc tensioners are installed respectively), S-shaped yarn guide plate, disc tensioner, electronic yarn clearer 6 and yarn detection rod 7, The winding device includes a fixed frame and a main motor arranged on the frame, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com