False twisting machine with winding equipment

A technology of false twist texturing machine and equipment, which is applied in the direction of textile and paper making, conveying filamentous materials, thin material processing, etc., to achieve the effect of reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

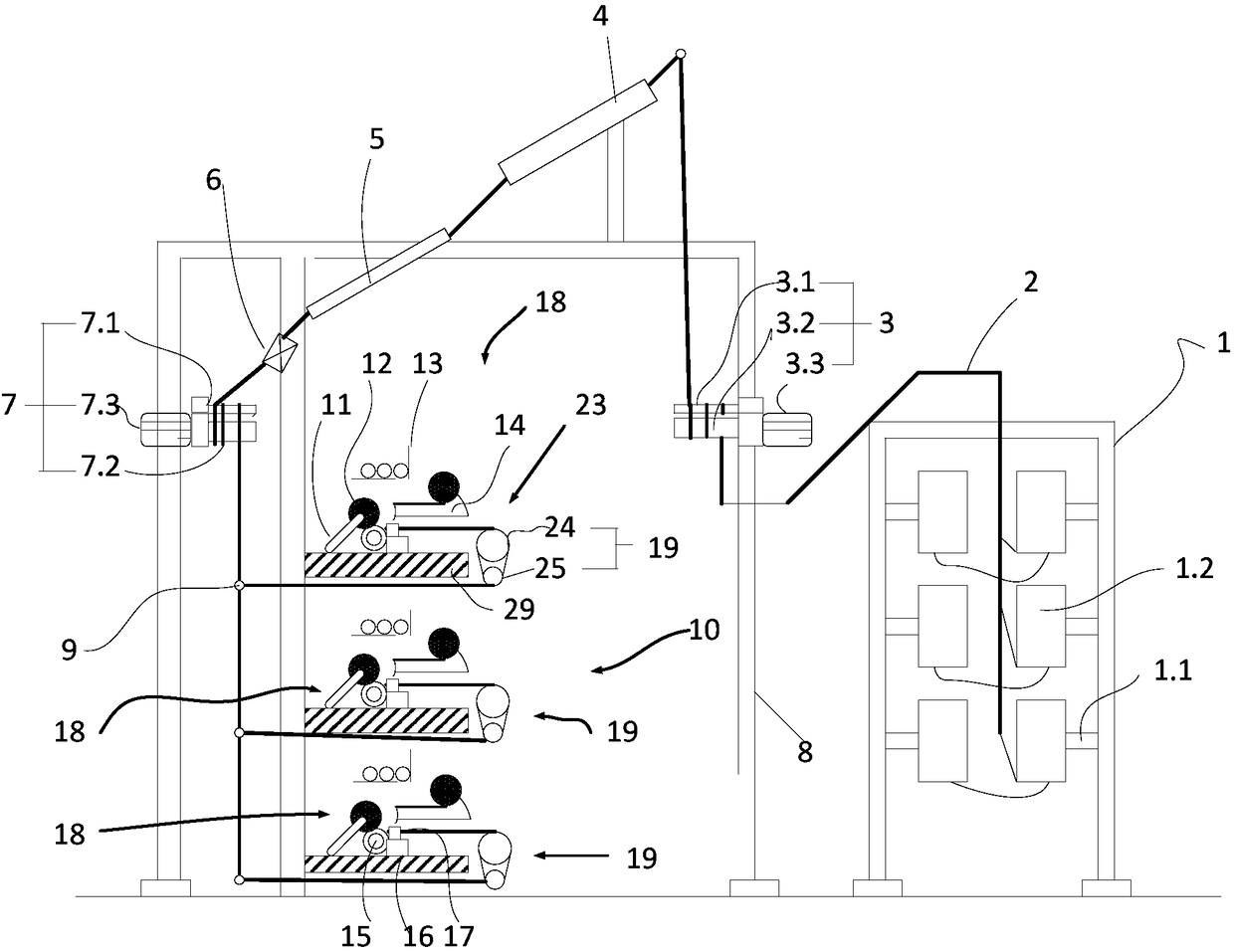

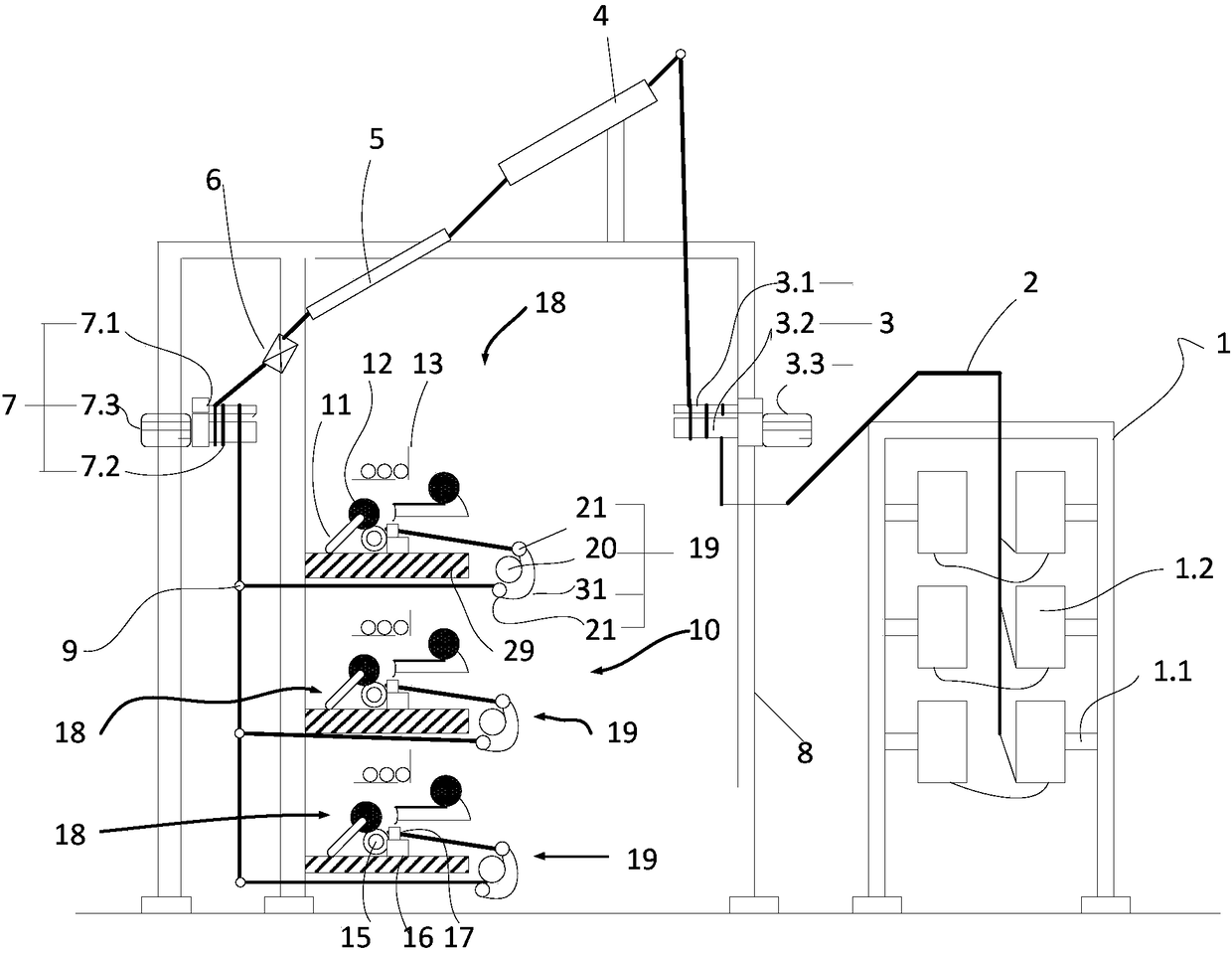

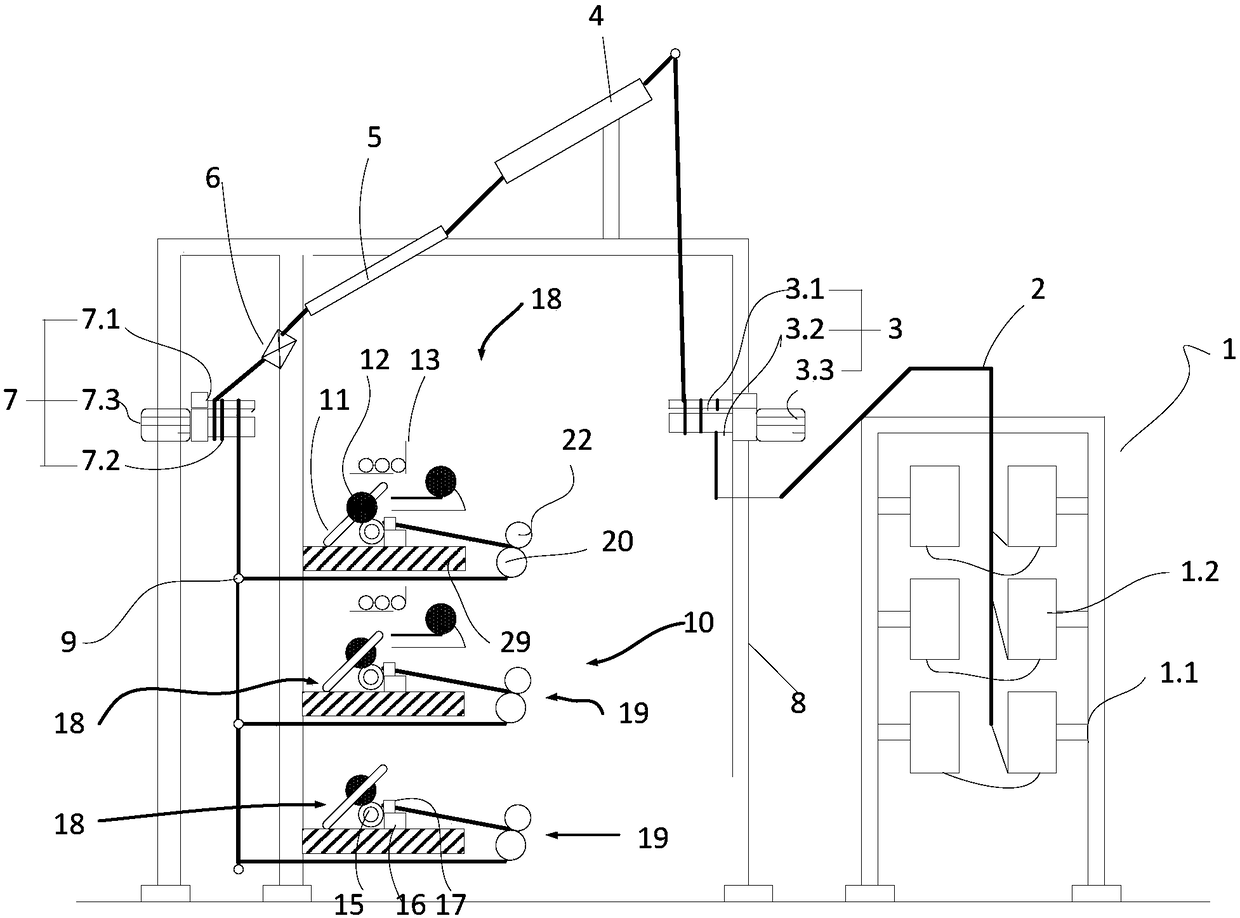

[0026] False twist texturing machines are used to process thermoplastic fibers such as polyester and nylon to obtain fibers with higher elasticity. As a first embodiment of the present invention, figure 1 A schematic cross-sectional view of a false twist texturing machine with a winding device according to the present invention is shown. Although different types of yarn require slightly different machine configurations, the basic configuration is basically the same, because the yarns of different models generally need to be drawn, heated, cooled, false twisted, stretched and was coiled. It should be noted that the "upstream side" or "downstream side" mentioned in the following descriptions all refer to the advancing direction of the yarn.

[0027] The following is an introduction to the structure of the false twist texturing machine according to the order in which the yarn is processed. The purpose of the false twist texturing machine is to process low-elastic pre-oriented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com