Manufacturing process of fermented soya beans

A manufacturing process, the technology of light tempeh, which is applied in the field of light tempeh manufacturing technology, can solve the problems of different softness and hardness of soybean grains, different hardness and chewiness of light tempeh, and reduce the quality of light tempeh, so as to ensure consistency and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

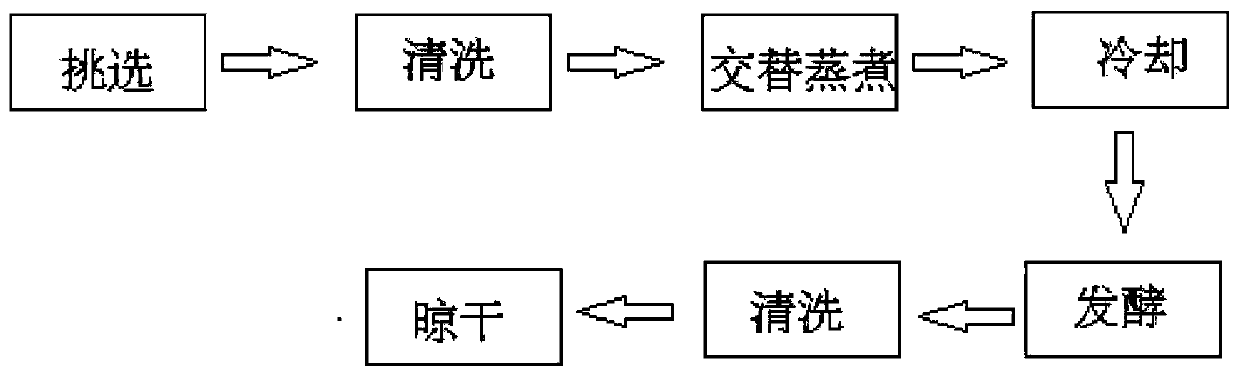

[0018] Such as figure 1 As shown, the present invention provides a kind of manufacturing process of soya bean, comprises the following steps successively:

[0019] S1. Selection: Select fresh soybeans without damage and mildew, and the fresh soybeans are mature and the grains are plump and even.

[0020] S2. Cleaning: washing the fresh soybeans with clean water to remove dust and impurities attached to the fresh soybeans.

[0021] S3. Alternate cooking: put the cleaned fresh soybeans into a steamer and cook them under normal pressure to obtain dry steamed soybeans. The cooking time is 28-30min; The surface is soaked with water for 9-11 minutes to obtain moistened soybeans. When watering, the mass ratio of dry stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com