Pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and production technology thereof

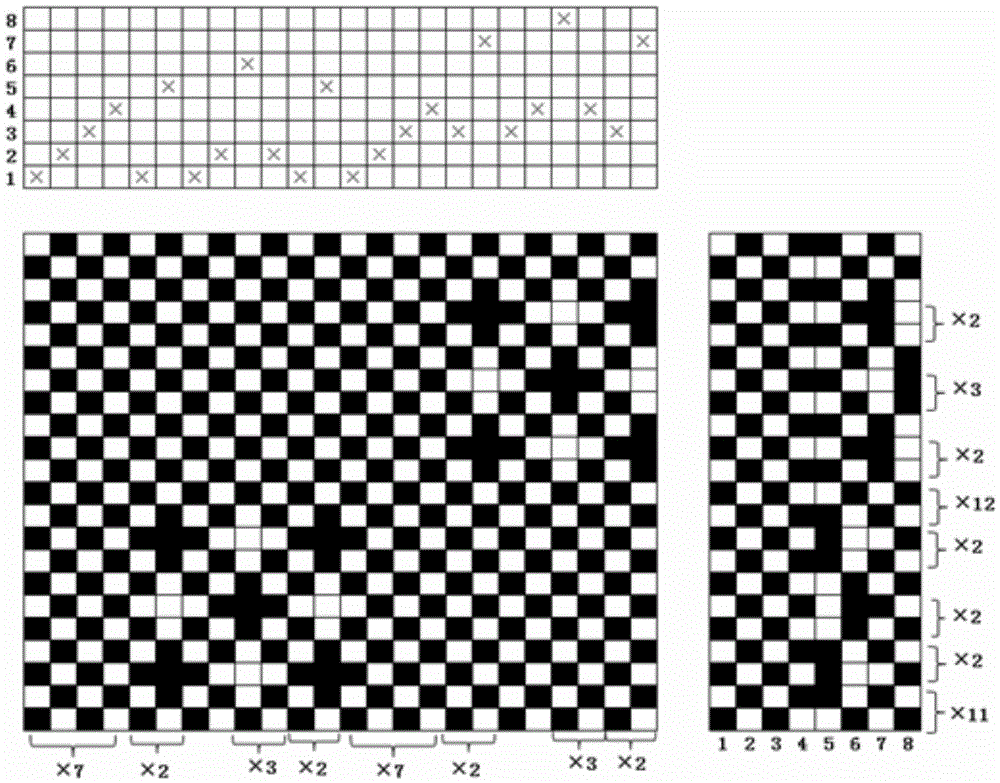

A kind of aloe vera fiber and production process technology, applied in fiber processing, plant fiber, textile and other directions, can solve the problems affecting production efficiency and product quality, yarn performance damage, serosal film is easy to fall off, etc., to achieve a clear and elegant overall effect of the cloth. , Light texture, simple pattern loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0035] A kind of production technology according to described pure aloe fiber warp and weft double-elastic yarn-dyed wrinkle cloth, comprises the steps:

[0036] Step (1), winding process:

[0037] Autoconer338 winding machine is adopted, the winding speed is set to 1100m / min, the winding tension is 33cN, and the winding density is 0.41g / cm 3 , in order to improve the yarn quality, the machine is equipped with USTERQUANTUM-2 electronic yarn clearer to improve the accuracy of removing harmful yarn defects such as neps, thick places, and fine details. The yarn clearing process parameters are set to neps + 350%, Short thick place +220%×2.0cm, long thick place +40%×40cm, long thick place -35%×40cm;

[0038] Step (2), warping process:

[0039] Since there are only two types of fabric dyed yarns and the pattern cycle is simple, Swiss BENNINGER (BENNINGER) ZDA batch warping machine is used; in order to enable the shed to be opened and cleared with a small tension on the machine dur...

specific Embodiment 2

[0047] A kind of production technology according to described pure aloe fiber warp and weft double-elastic yarn-dyed wrinkle cloth, comprises the steps:

[0048] Step (1), winding process:

[0049] Autoconer338 winding machine is adopted, the winding speed is set to 1400m / min, the winding tension is 36cN, and the winding density is 0.44g / cm 3 , in order to improve the yarn quality, the machine is equipped with USTERQUANTUM-2 electronic yarn clearer to improve the accuracy of removing harmful yarn defects such as neps, thick places, and fine details. The yarn clearing process parameters are set to neps + 350%, Short thick place +220%×2.0cm, long thick place +40%×40cm, long thick place -35%×40cm;

[0050] Step (2), warping process:

[0051] Since there are only two types of fabric dyed yarns and the pattern cycle is simple, Swiss BENNINGER (BENNINGER) ZDA batch warping machine is used; in order to enable the shed to be opened and cleared with a small tension on the machine dur...

specific Embodiment 3

[0059] A kind of production technology according to described pure aloe fiber warp and weft double-elastic yarn-dyed wrinkle cloth, comprises the steps:

[0060] Step (1), winding process:

[0061] Autoconer338 winding machine is adopted, the winding speed is set to 1300m / min, the winding tension is 35cN, and the winding density is 0.42g / cm 3 , in order to improve the yarn quality, the machine is equipped with USTERQUANTUM-2 electronic yarn clearer to improve the accuracy of removing harmful yarn defects such as neps, thick places, and fine details. The yarn clearing process parameters are set to neps + 350%, Short thick place +220%×2.0cm, long thick place +40%×40cm, long thick place -35%×40cm;

[0062] Step (2), warping process:

[0063] Since there are only two types of fabric dyed yarns and the pattern cycle is simple, Swiss BENNINGER (BENNINGER) ZDA batch warping machine is used; in order to enable the shed to be opened and cleared with a small tension on the machine dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com