Patents

Literature

98 results about "50S" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

50S is the larger subunit of the 70S ribosome of prokaryotes. It is the site of inhibition for antibiotics such as macrolides, chloramphenicol, clindamycin, and the pleuromutilins. It includes the 5S ribosomal RNA and 23S ribosomal RNA.

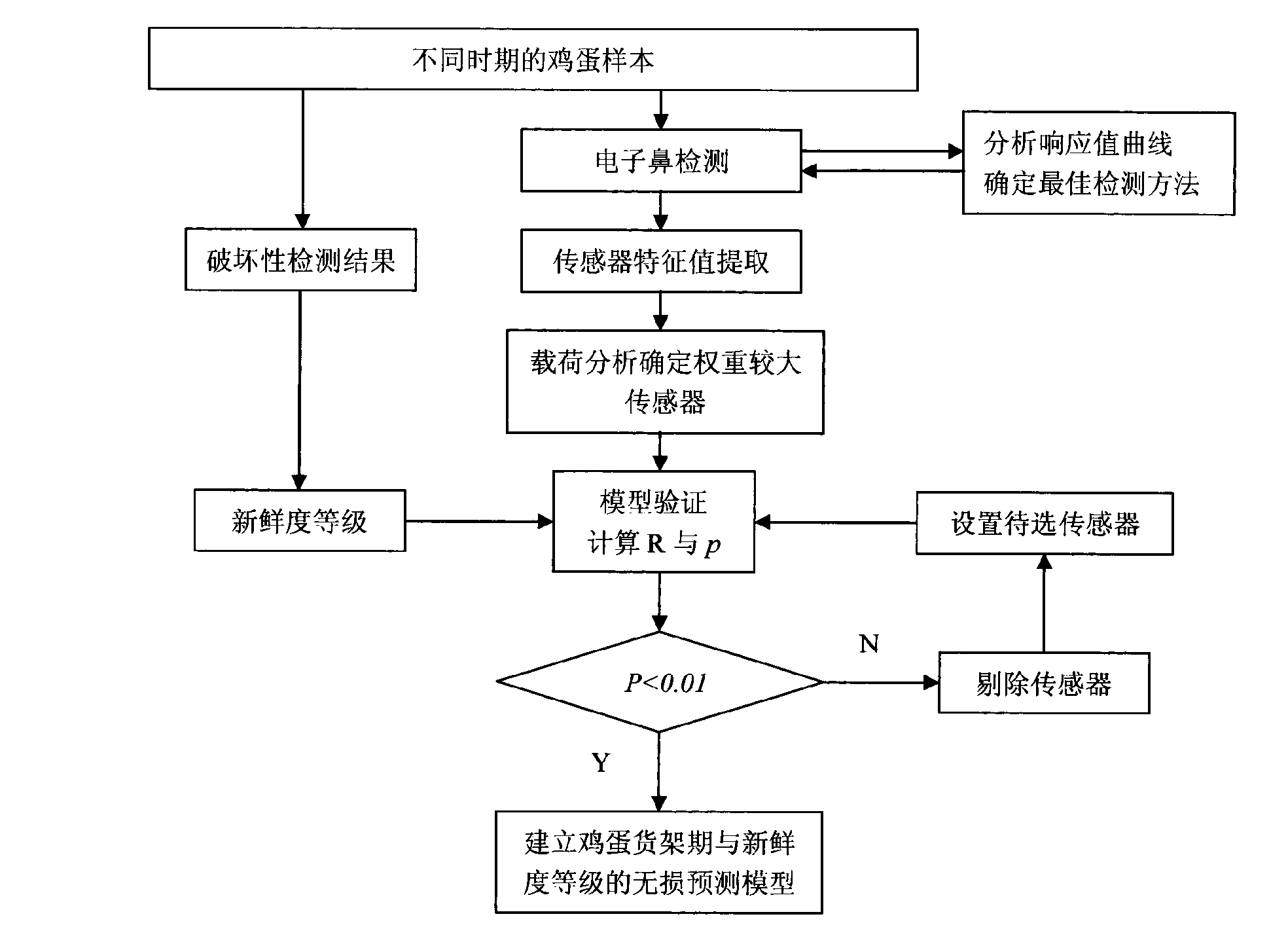

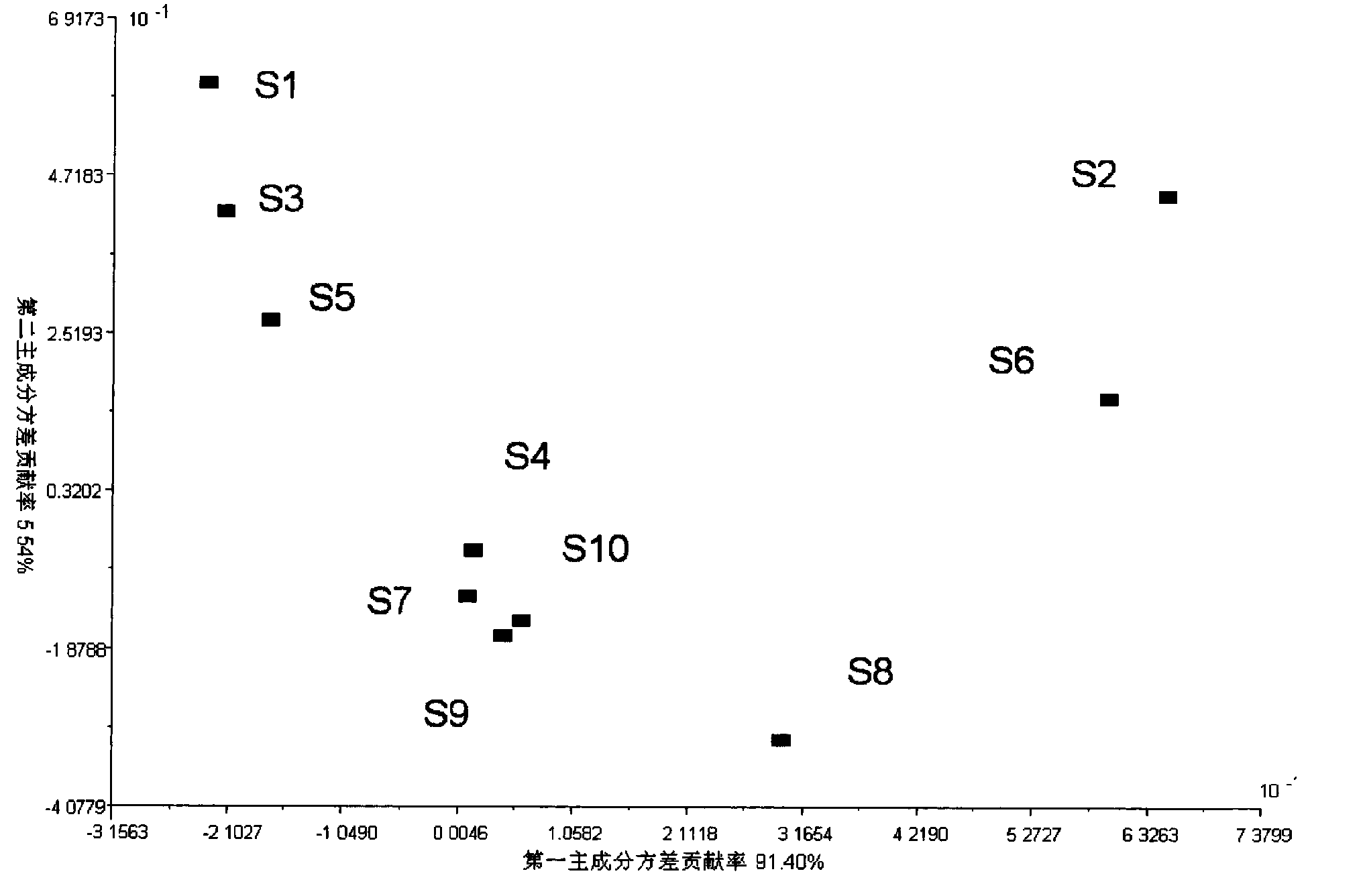

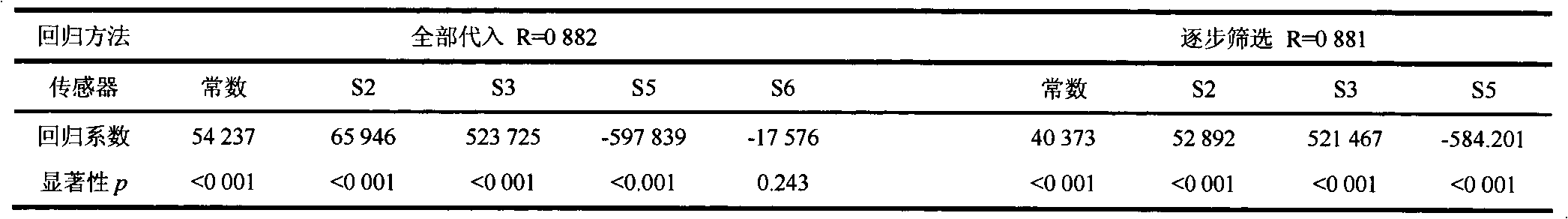

Method for detecting egg freshness by using gas sensor

The invention relates to a nondestructive detecting method for detecting egg freshness by using a gas sensor, belonging to the nondestructive detecting field of agricultural products. In the technicalmethod, a single egg is put in a 250ml of beaker, the proper value extracting time of an electronic nose is set to 50s, and the elution time is 90s; the proper value Sn of the sensor is brought intoan egg shelf life forecasting model or an egg freshness grade forecasting model, and then egg storage time under the condition of 20 DEG C and 70% RH of egg shelf life and the nondestructive detectedgrade of the egg freshness are respectively obtained. The method can rapidly and nondestructively detect the egg freshness so as to reduce the loss of the labor expenses and the detection time, and can monitor the quality of egg products in actual processes of production, circulation, storage and vendition. Meanwhile, the nondestructive detecting method optimizes sensor combination and reduces thedeveloping and manufacturing cost of instruments according to experimental results.

Owner:镇江凤来仪生态农业有限公司

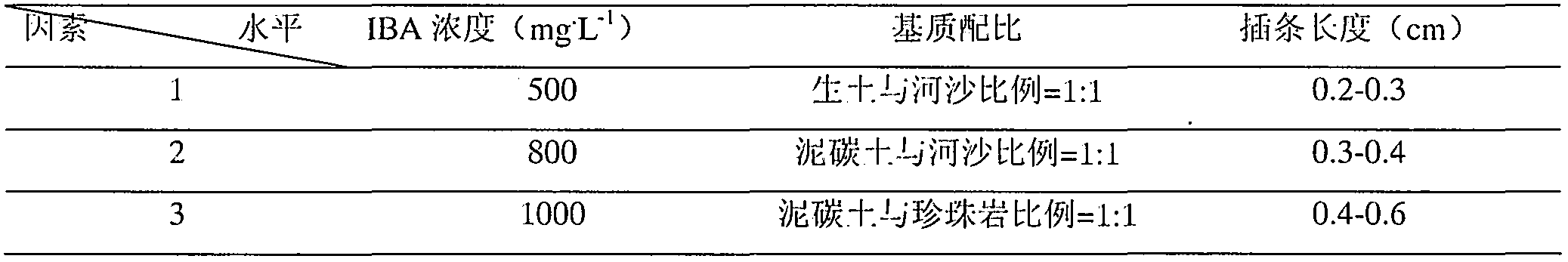

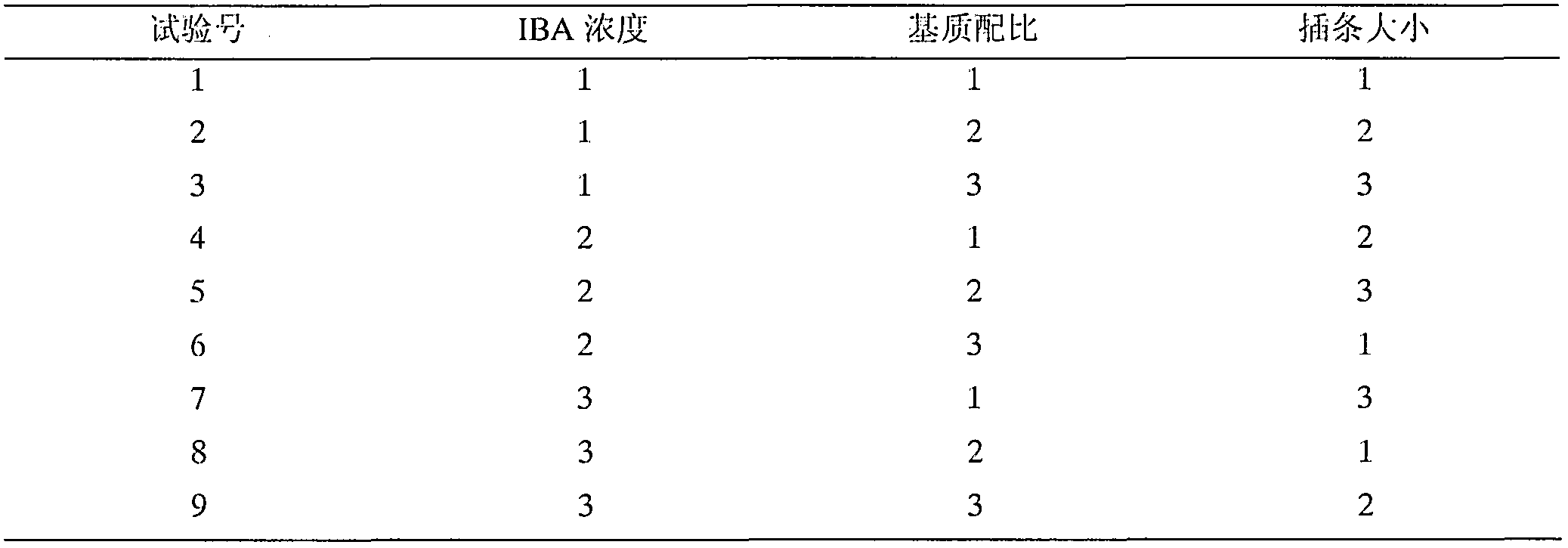

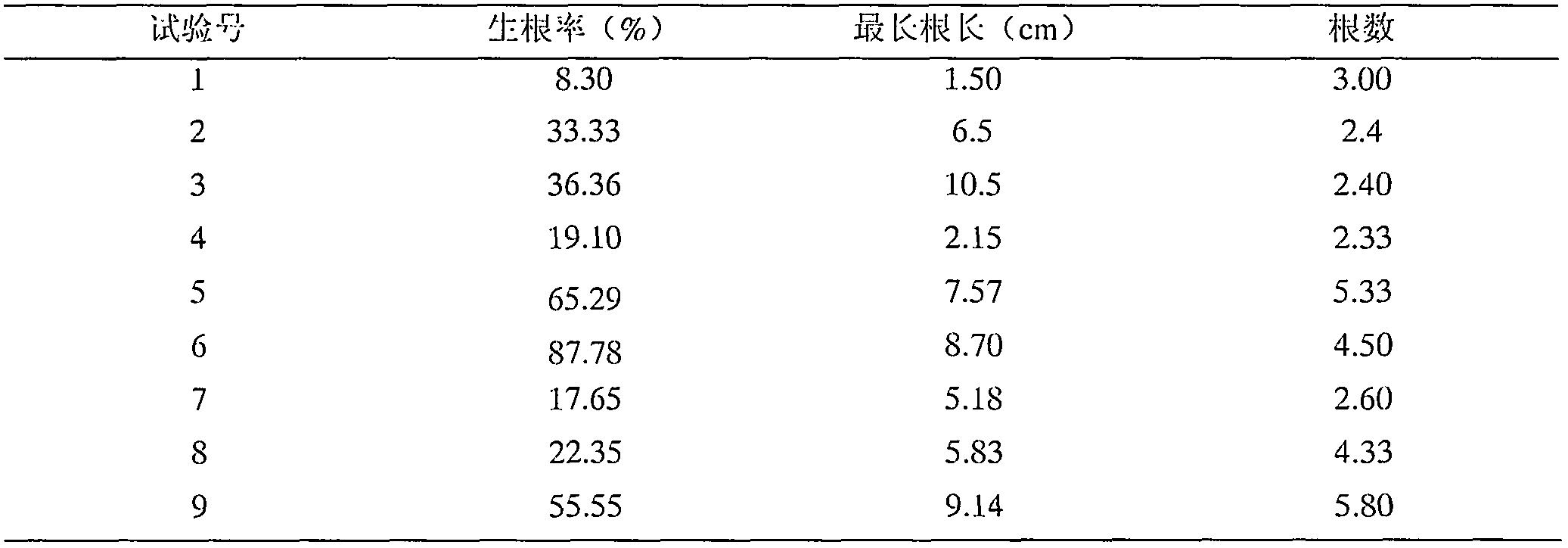

Propagation method for hard wood cutting of 'golden common vetch'

The invention provides a 'propagation method for the hard wood cutting of 'golden common vetch''. The propagation method is characterized by comprising the following steps of: selecting the annual 'golden common vetch' branches free of plant diseases and insect pests and with the coarseness within the range of 0.2-0.6cm in March, shearing into cutting slips with the lengths of 5-10cm, and soaking in water for 12-24 hours; dipping the roots of the cutting slips at 1.5-3.0cm for 10-20s by 75% ethyl alcohol, washing by clean water for 2-3s, inserting into 800-1000mg.L<-1> IBA (iso butyl alcohol) solution for 30-50s, and inserting into a matrix mixed by mire soil and perlite according to the proportion of 1:1, wherein the cottage depth is 1 / 2 of the length of the cutting slips, and one golden common vetch is inserted into every one hole disc; spraying water after cottage, so that the branches are tightly contacted with the matrix; and entering a seedling exercising period when the rooting percentage of the cutting slips reaches up to 60-70% of a sword, and planting when the seedling exercising time is 10-15d. The survival percentage of the cutting slips of 'golden common vetch' propagated by the method disclosed by the invention can reach to be more than 80% of the sword under the condition of a fog system, and the method is ordered in nursery stock, enough in delayed effect, and extremely good in commodity.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

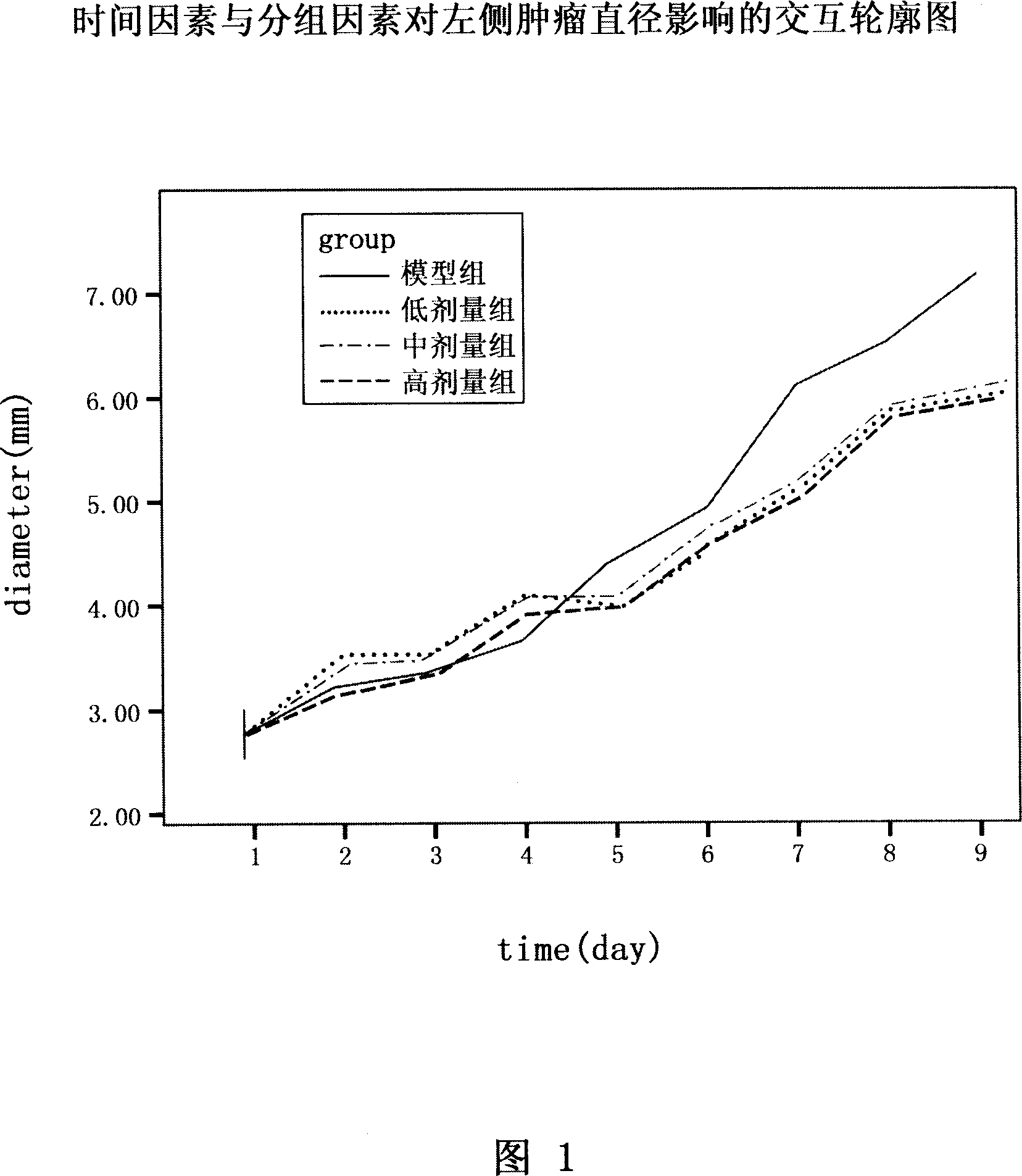

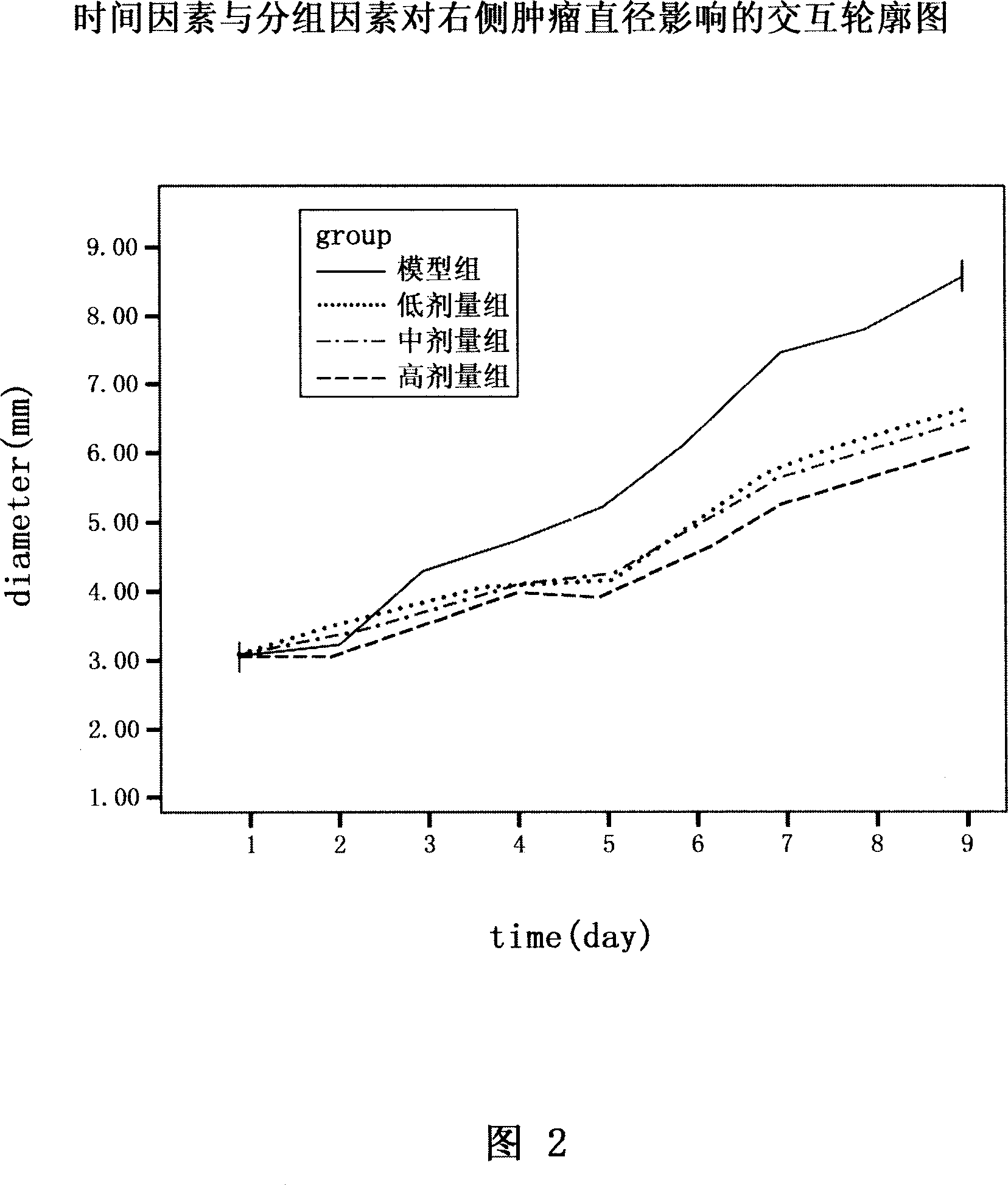

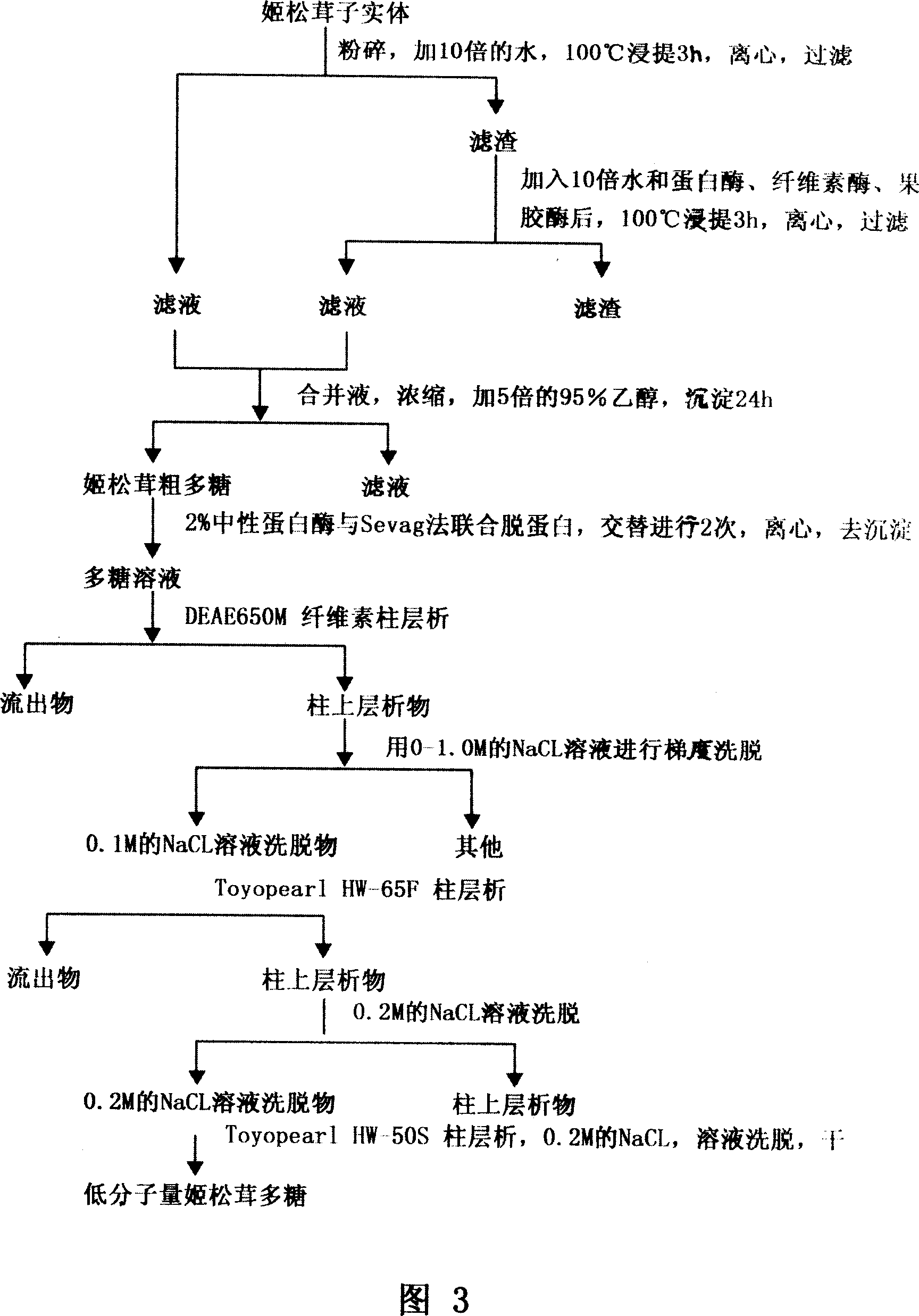

Low molecular Brazil mushroom polysaccharide and its prepn process and application in antagonizing tumor metastasis

InactiveCN101067006AHigh purityImprove performanceOrganic active ingredientsFungi medical ingredientsChromatographic separationCellulose

The present invention discloses one kind of low molecular Brazil mushroom polysaccharide and its preparation process and application in antagonizing tumor metastasis. The low molecular Brazil mushroom polysaccharide extracted from the sporophore of edible fungus Brazil mushroom has homogeneous glucosan in molecular weight of 48,000 as the main component. It is prepared with sporophore of Brazil mushroom, and through crushing, leaching in distilled water, precipitating in alcohol to obtain coarse Brazil mushroom polysaccharide product, deproteinizing, chromatographic separation in DEAE650M cellulose column, gradient eluting with NaCl solution, chromatographic separation of eluted liquid in Toyopearl HW-65F column, eluting with NaCl solution, chromatographic separation of eluted matter in Toyopearl HW-50S column, eluting with NaCl solution, and drying.

Owner:QIQIHAR MEDICAL UNIVERSITY

Wear-resistant composite wood plate working method

InactiveCN1935474AImprove flatnessUniform internal stressPlywood pressesVeneer pressesWear resistantFree cooling

The present invention relates to a production method of wear-resistant composite wooden plate. Said production method includes the following several steps: cutting log to obtain single plate, drying, water content of single plate is less than or equal to 7%, the thickness of top layer single plate is greater than that of lower portion single plate, gluing, prepressing at normal temperature by using 12MPa-18MPa, retaining pressure for 15 min-20 min, hot-pressing by using 14MPa-22MPa at 110-130 deg.C, retaining pressure for 3 min-12 min, placing wear-resistant decorative layer, hot-pressing by using 14-20MPa at 160-190 deg.C, retaining pressure for 30s-50s, cooling and cutting so as to obtain the invented finished product.

Owner:孙维

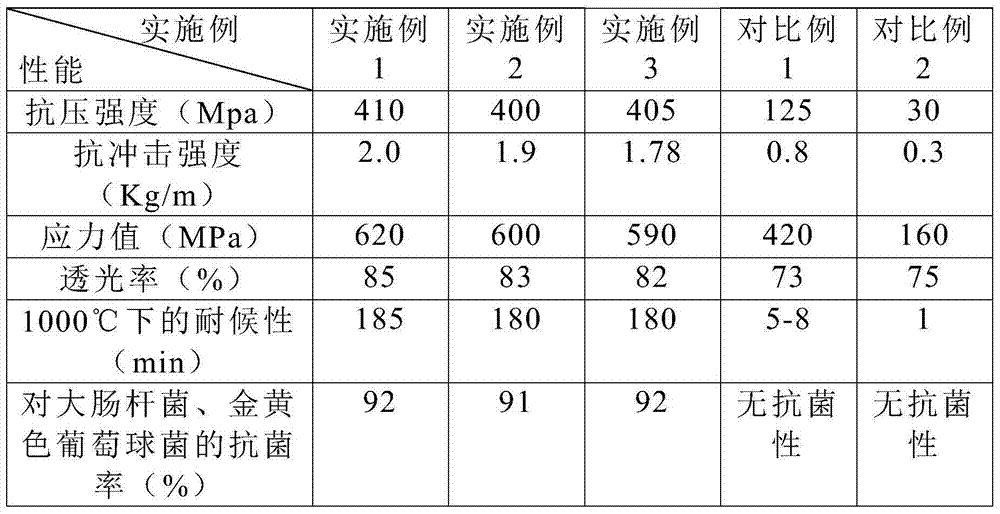

Processing technology for single-sheet cesium potassium fireproof glass

InactiveCN104291688AImprove fire protectionImprove antibacterial propertiesGlass tempering apparatusThermal insulationPotassium

Belonging to the technical field of building materials, the invention relates to a processing technology for a single-sheet cesium potassium fireproof glass. The processing technology comprises the following steps of: pretreatment of glass: conducting surface acid treatment on glass, then carrying out cleaning, drying and preheating to 380-400DEG C, and performing thermal insulation for 25-30min; ion exchange treatment: subjecting the glass to ion exchange treatment in a cesium potassium salt solution at 550-650DEG C for 18-22h; heat treatment: performing heat treatment on the glass subjected to the ion exchange treatment at 690-710DEG C, with the heating time being 40-50s per millimeter thickness; air cooling molding: taking out the glass and sending the glass into an air grid at a speed of 300-500mm / s to undergo air cooling molding, and finally conducting cooling to obtain the single-sheet cesium potassium fireproof glass. The processing technology provided by the invention is simple and practicable, and the prepared glass not only has very good fireproof function, but also has high strength, weathering resistance and machinability.

Owner:NINGBO HEXIN GLASS TECH

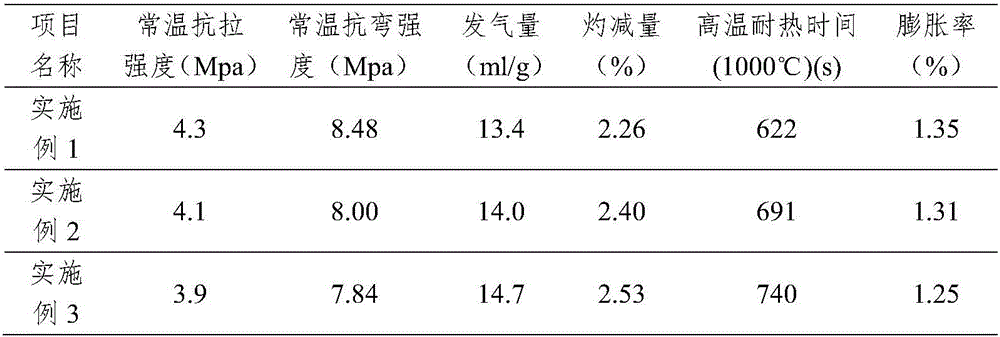

Preparation method of high temperature-resistant type precoated sand

The invention discloses a preparation method of a high temperature-resistant type precoated sand. The preparation method specifically comprises the following steps of 1, heating raw sand, adding the raw sand into a sand mixing machine after the sand temperature is increased to 140 to 160 DEG C, adding an adhesive, mixing the sand, and stirring for 20 to 120s, so as to obtain adhesive sand; after the adhesive is completely melted, sequentially adding high temperature-resistant additive and lubricant, continuing to stir, and uniformly dispersing the additive and the lubricant into the adhesive; 2, stopping heating, adding a curing agent after the sand temperature is decreased to 90 to 110 DEG C, and mixing for 20 to 50s, so as to obtain curing agent sand; 3, adding the lubricant into the curing agent sand, mixing the sand for 20 to 120s, adding the lubricant again after the sand temperature is decreased to 70 to 80 DEG C, mixing for 10 to 30s, and discharging sand, so as to obtain the high temperature-resistant type precoated sand. The high temperature-resistant type precoated sand prepared by the preparation method has the advantages that the fluidity is good, the high temperature heat-resistant time is long, the expansion rate is low, the anti-crack and anti-sand sticking effects are realized, and the like.

Owner:西峡县北雁铸造材料有限公司

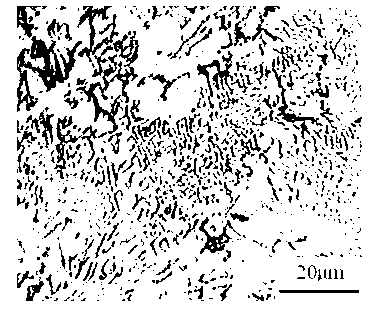

Method for preparing aluminum cerium intermediate alloy through high-intensity ultrasound

A method for preparing aluminum cerium intermediate alloy through high-intensity ultrasound comprises the following steps of: (1) placing pure aluminum ingots in a crucible for heating to melt, wrapping rare earth cerium particles in the diameter of 20-100mu m by using aluminized paper, pressing in the pure aluminum melt, keeping warm for 20-30 minutes at the temperature of 725DEG C-745 DEG C, and enabling the rare earth cerium content to be 18% of the total weight; (2) stretching a ultrasonic amplitude transformer in a position which is 8-15mm away from a liquid level of alloy melt to conduct batch-type high-intensity ultrasound and enabling ultrasound intensity to be 0.6kw / cm<2>-0.8 kw / cm<2>; (3) enabling ultrasound execution time to be 8-15 minutes, enabling each time of high-intensity ultrasound execution time to be 30-50s, and enabling rest time to be 30-50s; and (4) cooling the alloy melt to 700DEG C-710 DEG C for refining and impurity removing, and conducting pouring. The method is low in melting temperature, capable of effectively avoiding burning loss of rare earth, stable in rare earth content, low in energy consumption, simple in process, safe, reliable and uniform in alloy content and reduces segregation.

Owner:NANCHANG UNIV

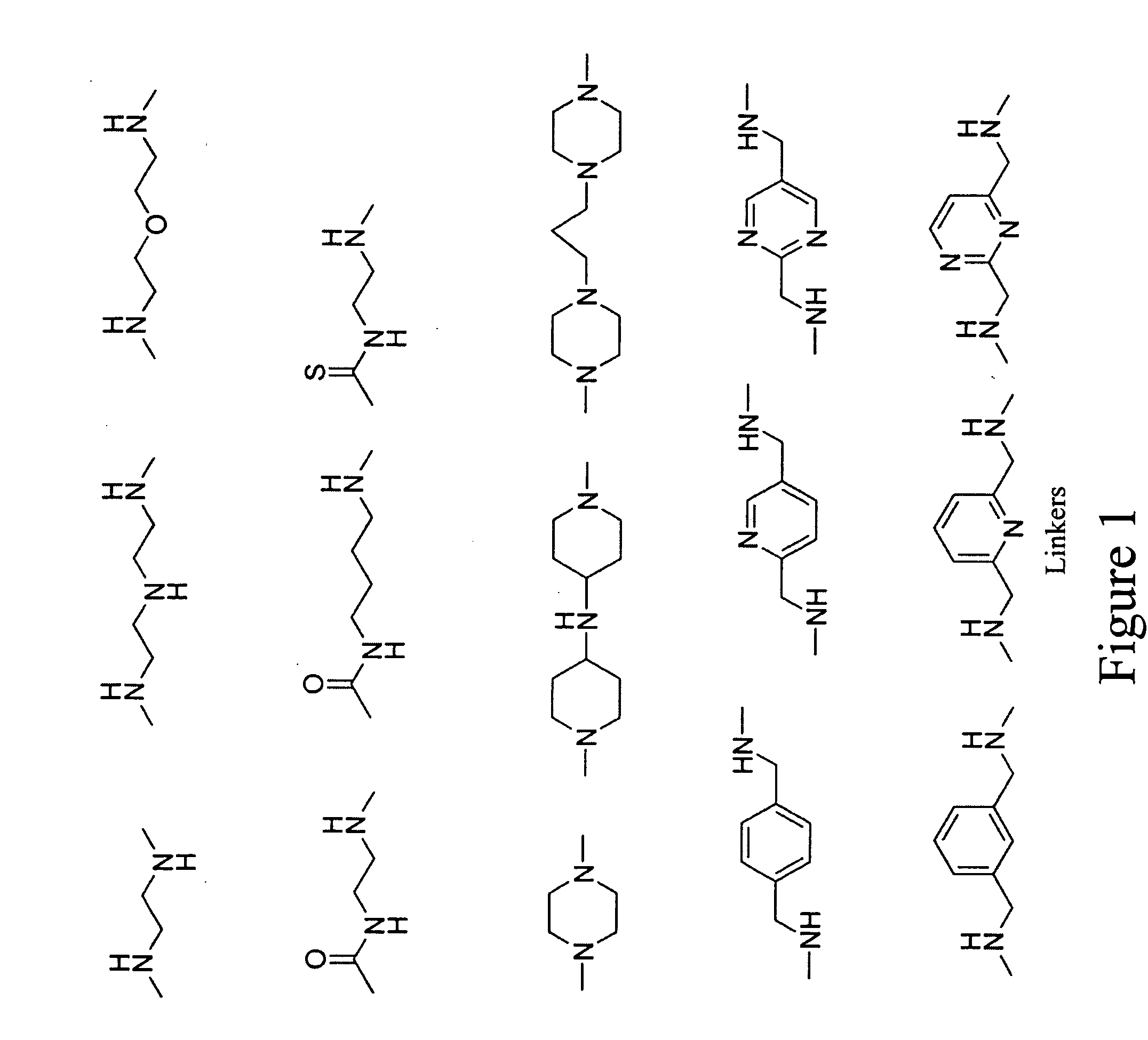

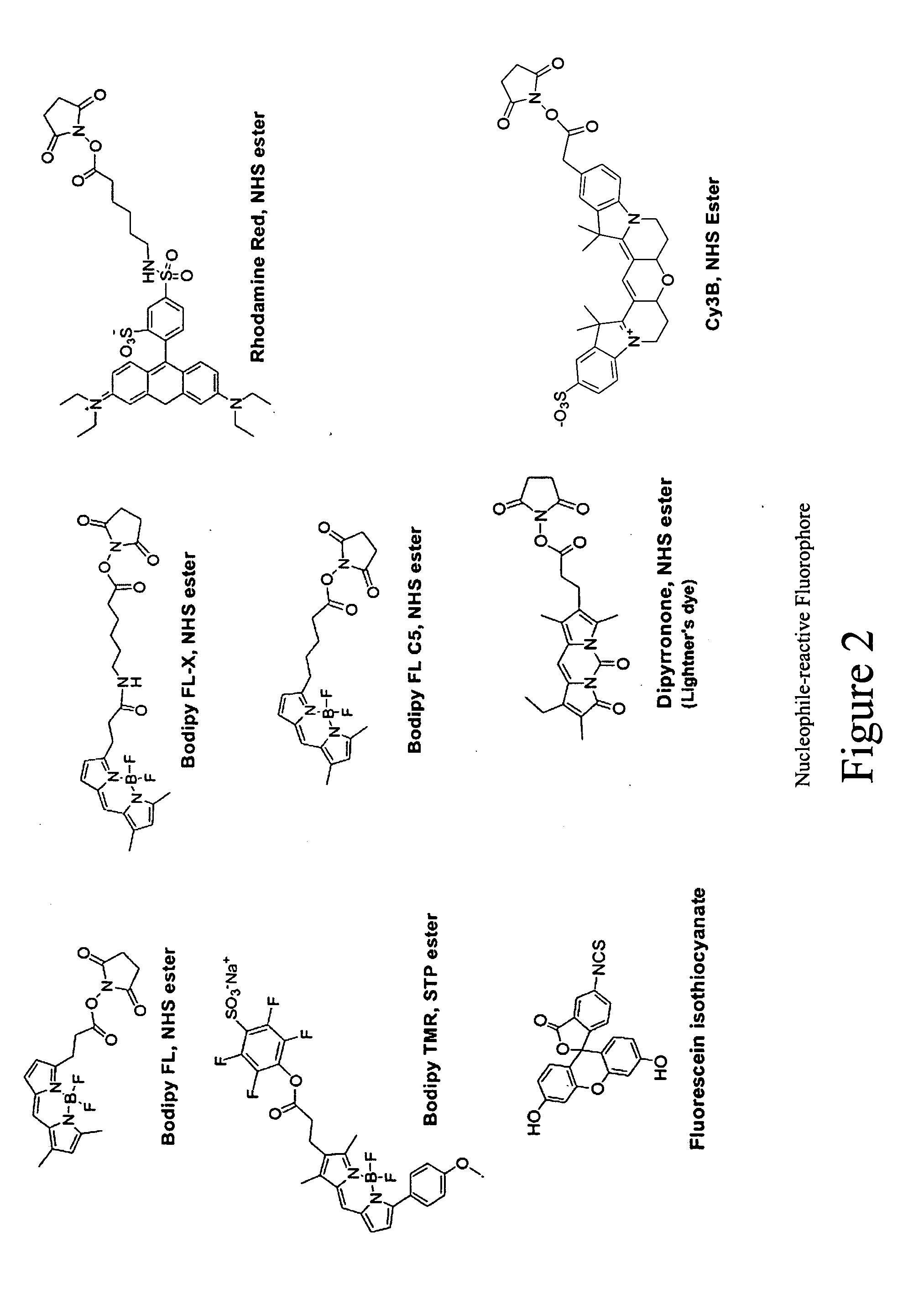

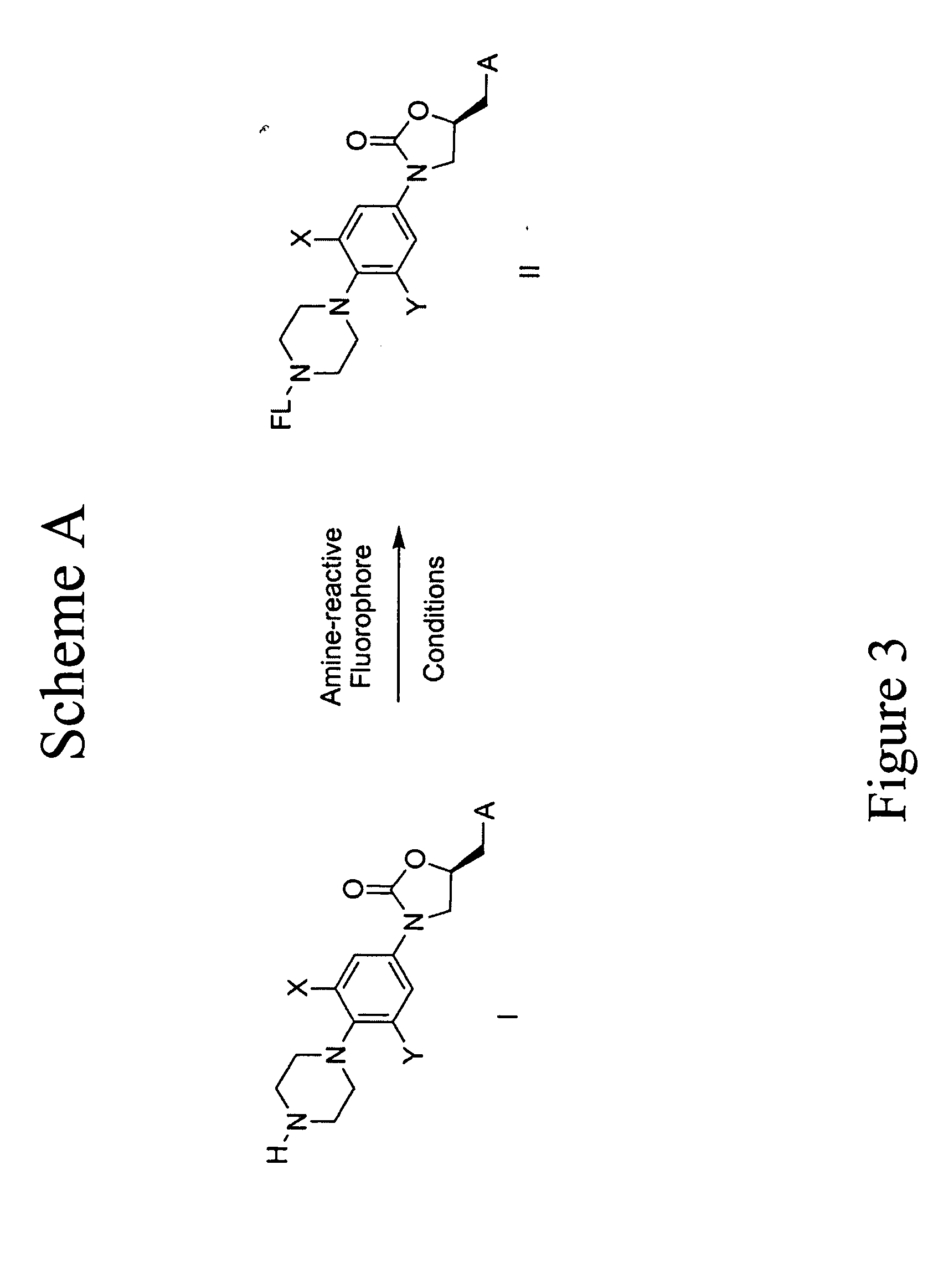

Fluorescent probes for ribosomes and method of use

InactiveUS20050118624A1High-throughput screeningSilicon organic compoundsCompound screeningFluorescence50S

Fluorescent probes that have binding affinity to ribosomes. The fluorescent probes are useful tools for identifying small molecules that bind to the 50S or 30S subunits of the bacterial and other ribosomes and serve as novel ribosome inhibitors. These probes are also useful for determining the interactions between a specific ligand and the ribosome.

Owner:CUMBRE

Pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and production technology thereof

The invention discloses pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and a production technology thereof. The pure aloe fiber warp and weft double-elasticity yarn-dyed fabric comprises a warp yarn, a weft yarn and an elastic yarn, wherein 60S aloe fiber yarns are adopted as the warp yarn and the weft yarn; aloe 50S / 20D is adopted as the elastic yarn; a plain fancy cellular structure is adopted as a fabric structure; a bottom structure formed by plain as main material and triple fancy cellular structures in the transverse direction and longitudinal direction; an edge structure is the plain; and a jacquard part is formed by the fancy cellular structure as main part in transverse direction and horizontal direction matched with the shrinkage action of an aloe fiber spandex core-spun yarn. The production technology comprises a spooling step, a warping step, a slashing step, a drafting step and a weaving step. The fabric is reasonable in color match, light and thin in texture and slight in wrinkle, and gives a casual feeling to a consumer. Meanwhile, the pattern is relatively large in cycle, and is matched with unique plain fancy cellular structure, so that the fabric is high in third dimension and good in breathability. The weaving efficiency reaches 91%; and the first grade percentage put in storage reaches 99%.

Owner:IANGSU COLLEGE OF ENG & TECH

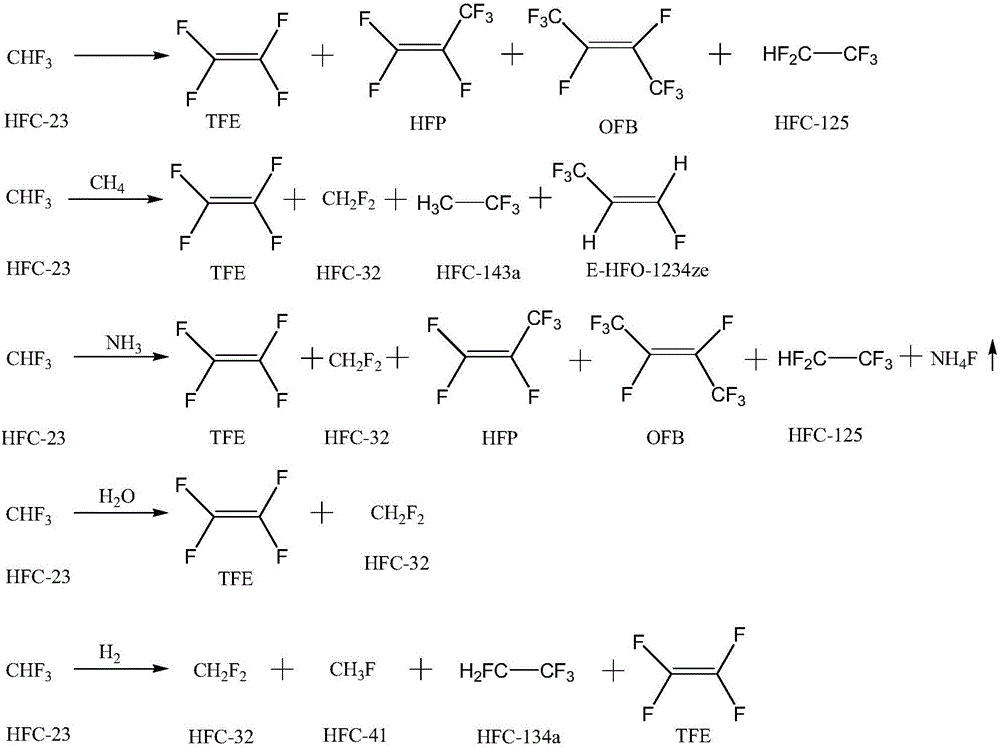

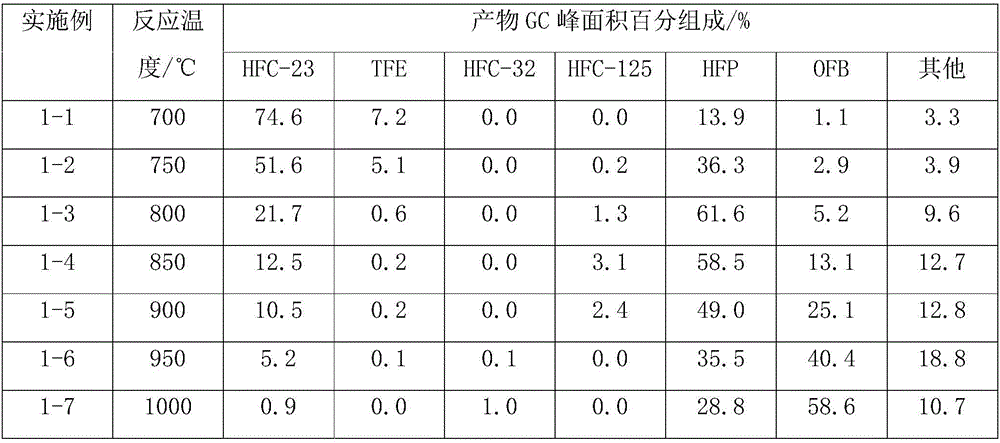

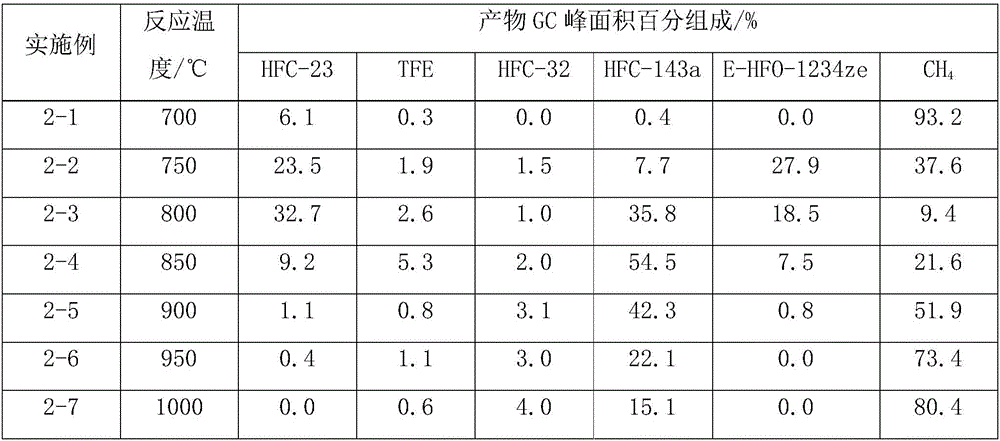

Method for preparing fluorinated compound CFR1=CFR2 (R1, R2=F or -CF3) through trifluoromethane thermolysis

ActiveCN106565410ANo deactivationGood repeatabilityHydrocarbon by hydrogenationHalogenated hydrocarbon preparationHydrogenReaction temperature

The invention discloses a method for preparing a fluorinated compound CFR1=CFR2 (R1, R2=F or -CF3) through trifluoromethane thermolysis. The method comprises the following steps that under the condition of no catalyst, trifluoromethane takes a gas phrase reaction with CH4, NH3, H2O or hydrogen gas to obtain the fluorinated compound under the reaction conditions that the reaction pressure is 0.1 to 1.5 MPa; the reaction temperature is 700 to 1000 DEG C; the mol ratio of the trifluoromethane to any one or several kinds of materials of CH4, NH3, H2O or hydrogen gas is (1:0) to (1:40); and the dwell time is 0.1 to 50s. The method provided by the invention has the advantages that the raw materials can be easily obtained; a catalyst does not need to be used; the operation and the control are easy; in addition, the experiment repeatability is high; and meanwhile, the conversion and reutilization of HFC-23 are well realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Process for blending mulberry bark and cotton into bedding fabric as well as printing pattern design

InactiveCN103320934AMany layers without chaosWith skin careDuplicating/marking methodsWoven fabricsYarnWrinkle skin

The invention discloses a mulberry bark / cotton blended bedding fabric and a design of Chinese-style blue and white printing patterns. The design comprises a yarn spinning process, a weaving process and a printing pattern design. The bedding fabric adopts a fabric specification of 136', adopts compact spinning 50S* and vortex spinning 40 S / 179 * 115, adopts the matching ratio of mulberry bark to cotton in weft and warp yarn to be 30:70, adopts five-shaft warp satins structures and comprises total 24,340 pieces of warp yarn. The Chinese-style blue and white printing patterns of the bedding fabric take blue as a theme color, adopt blue and white and auspicious cloud elements, are designed in a two-side continual / independent pattern form, have multiple layers without disorder and attach an implied meaning of a beautiful future. According to the design, comfort, renewability and biodegradability of natural cotton fiber are preserved, silkiness lustre, antibacterial property, wear resistance and wrinkle resistance are endowed to the fabric simultaneously, and the requirements for a top-grade fabric are met in the aspects of softness and fineness of the fabric. The manufactured bedding fabric has all excellent characteristics of fabrics, shows semitransparent blue patterns due to conversion of color gradation of the patterns, vividly shows new Chinese style charm, and makes people feel elegant and stable.

Owner:YANCHENG INST OF IND TECH

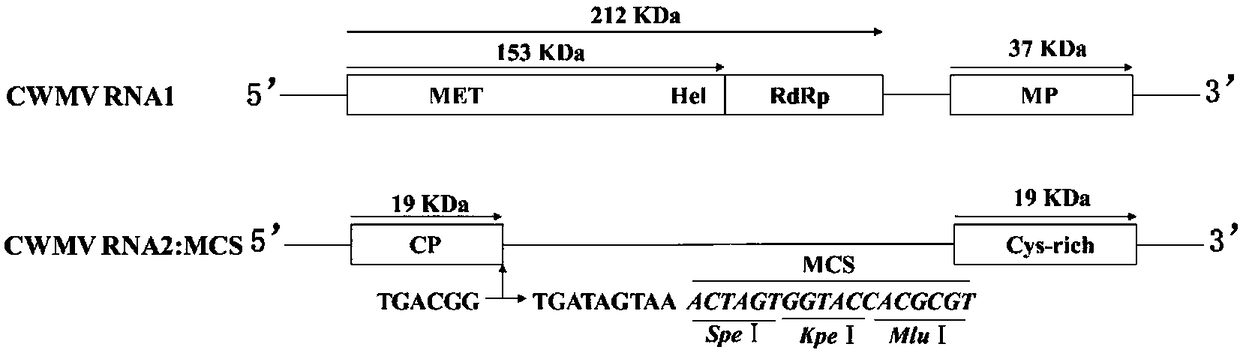

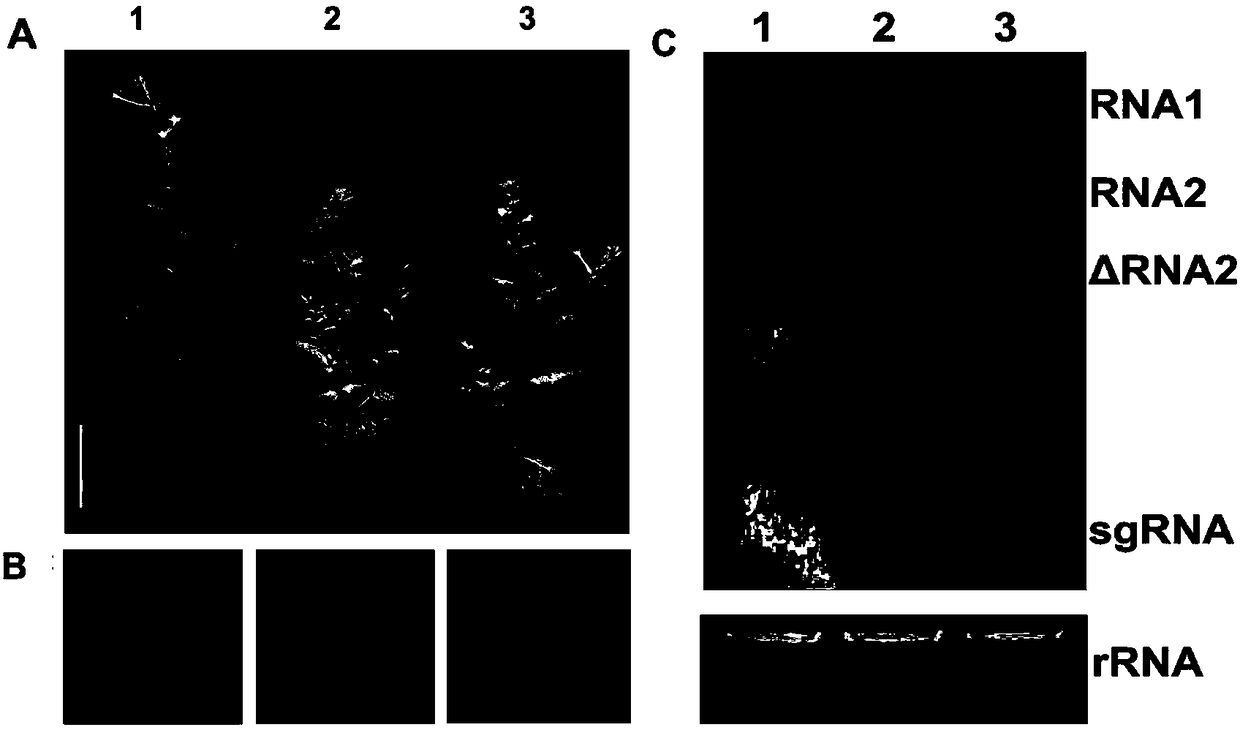

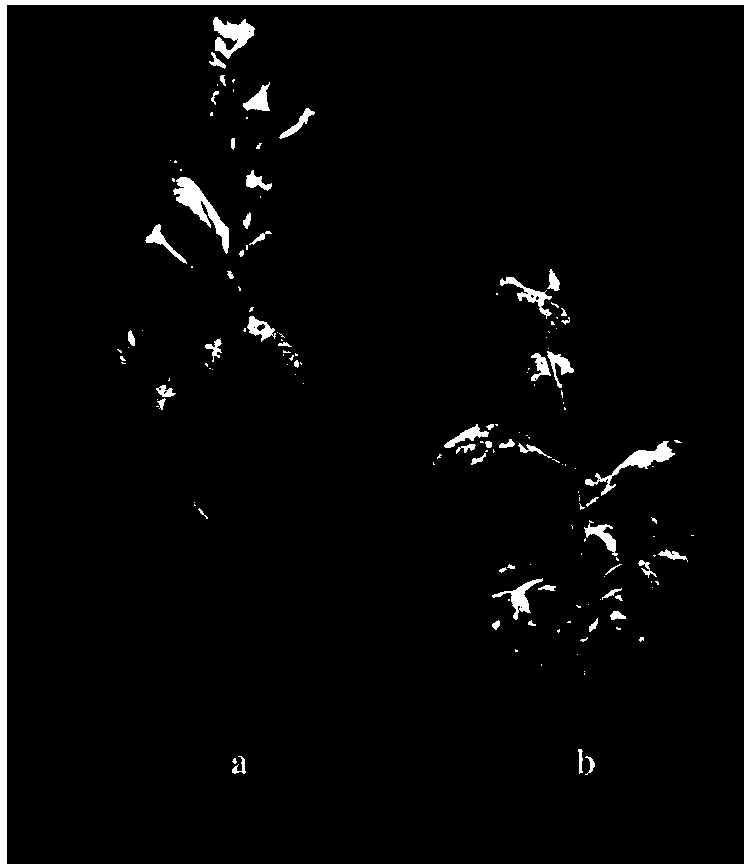

Construction and application of gene silencing vector induced by Chinese wheat yellow mosaic virus

InactiveCN108517332ARich varietyVector-based foreign material introductionAngiosperms/flowering plantsRibosomal proteinTriticeae

The invention mainly relates to construction of a gene silencing vector induced by Chinese wheat yellow mosaic virus, and application thereof to nicotiana benthamiana. The biological active analysis results show that the constructed CWMV-VIGS can successfully infect the nicotiana benthamiana and can realize the silencing after the effective transcription on relevant genes such as phytoene desaturase and 50S ribosomal protein L12. The types of the VIGS vectors are enriched; in addition, the effective technical measures are provided for the gene function study.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Method for processing leather-making malodorous gas by biological filter

InactiveCN102029107AEfficient removalReduce pollutionDispersed particle separationSustainable biological treatmentSludgeBiological filter

The invention provides a method for processing leather-making malodorous gas by a biological filter, comprising the following steps of: firstly, adding nutrient fluid into waste water and aerating; next, adding trimethylamine, NH4Cl and sulfureted hydrogen into the waste water to acclimate and inoculating mud into filling when the concentration of the mud reaches 4-5g L<-1>, wherein the filling is a compound material comprising porcelain granules, national clinoptilolite and Pall rings, the volume of the filling is 5-10m <3>, and microorganisms are attached on the surface of the filling; then, pumping waste gas into a humidifier and spraying the malodorous gas which enters the humidifier at the same time; and after the sprayed malodorous gas enters the bottom of a biological filtering tank, diffusing the sprayed malodorous gas to a filling layer through a gas distribution plate in an upflow mode, wherein malodorous components are adsorbed and intercepted by a biological film on the filling and finally adsorbed and utilized by microbial populations attached on the surface of the filling after stopping 30-50s in a filtering bed, and purified gas is exhausted by an exhauster. The invention has a good removing function on malodorous gas of a leather-making industry, reduces air pollution and increases production efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

Processing method of polylactic acid fiber-silk interlaced necktie fabric

The invention discloses a processing method of polylactic acid fiber-silk interlaced necktie fabric which adopts polylactic acid fiber and silk to interlace and prepare simple twill or satin weaves. The processing method is characterized in that the 75-150D of polylactic acid fiber filament is used as weft and the silk as warp is used as warp to interlace, then presetting is performed at 120-130 DEG C for 40-60s, then preshrinking is performed at 120-130 DEG C for 40-80s with the preshrinking rate of 10-15%, and then nano-finishing is performed by using 1-3g / L of nano-finishing agent at 105-115 DEG C for 30-50s. The invention resolves the process problem of using core filament- silk interlaced fabric to prepare necktie, reduces the process cost of silk necktie and is characterized by gorgeous colour, soft hand feeling, and good elasticity and drapability.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Preparation method of sodium calcium silicate glass bottles

ActiveCN108117267AImprove the strengthening and toughening effectImproved high thermal shock resistanceGlass blowing apparatus50SMagnesium

The invention relates to a preparation method of sodium calcium silicate glass bottles. The preparation method specifically comprises the following steps: (1) weighing quartz sand, crushed glass, limestones, sodium carbonate, sodium nitrate, borax, barium carbonate, magnesium carbonate, mullite crystal whiskers, silicon nitride crystal whiskers, cerium oxide powder and selenium powder; and ball-milling and mixing the components to obtain a mixed material; (2) feeding the mixed material into a smelting furnace, wherein the temperature of the mixed material reaches 1570-1600 DEG C, and keeping the temperature for 9-11h; and (3) cooling a glass stock solution to 1320-1350 DEG C, and blowing and forming the glass bottles; converting the glass bottles to an annealing furnace at 420-430 DEG C, keeping the temperature for 80-130min first, then heating the glass bottles to 500-520 DEG C, keeping the temperature for 80-120min, taking out the glass bottles, cooling the glass bottles for 6-9s with a air flow at 35-40 DEG C, and then cooling the glass bottles for 30-50s with a air flow at 9-15 DEG C. The internal stresses in the glass bottles can be removed effectively, and the glass bottles keep relatively good strength, and are good in impact resistance, breakage-proof and stable in chemical property.

Owner:安徽钦同瓶业有限公司

Method for reducing semisteel steel-making final slag total iron content

The invention relates to a method for reducing semisteel steel-making final slag total iron content and belongs to the technical field of metallurgy. The invention aims at providing the method for reducing the semisteel steel-making final slag total iron content. The method comprises the following steps: adding a magnesium carbon ball after finishing semisteel converter smelting, performing top-blowing nitrogen for 20-50s, standing for 60-120s after finishing nitrogen blowing, and tapping. By adopting the method, the semisteel steel-making converter final slag TFe content is controlled within 18%, the final slag TFe is obviously reduced and the effect is obvious, additionally the method is simple in operation, few in magnesium carbon ball dosage and low in cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

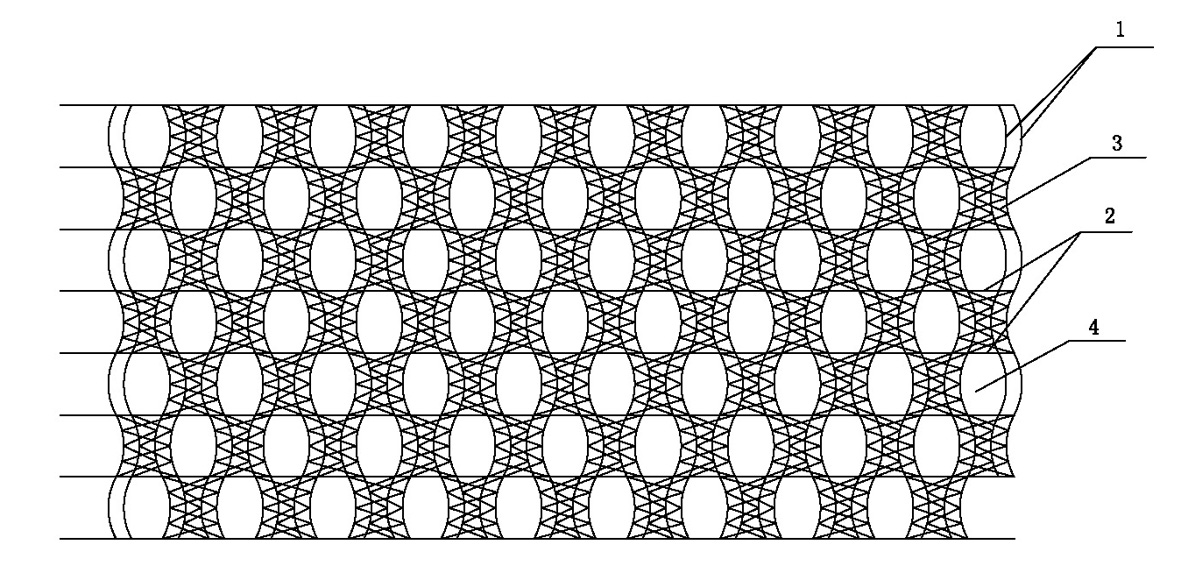

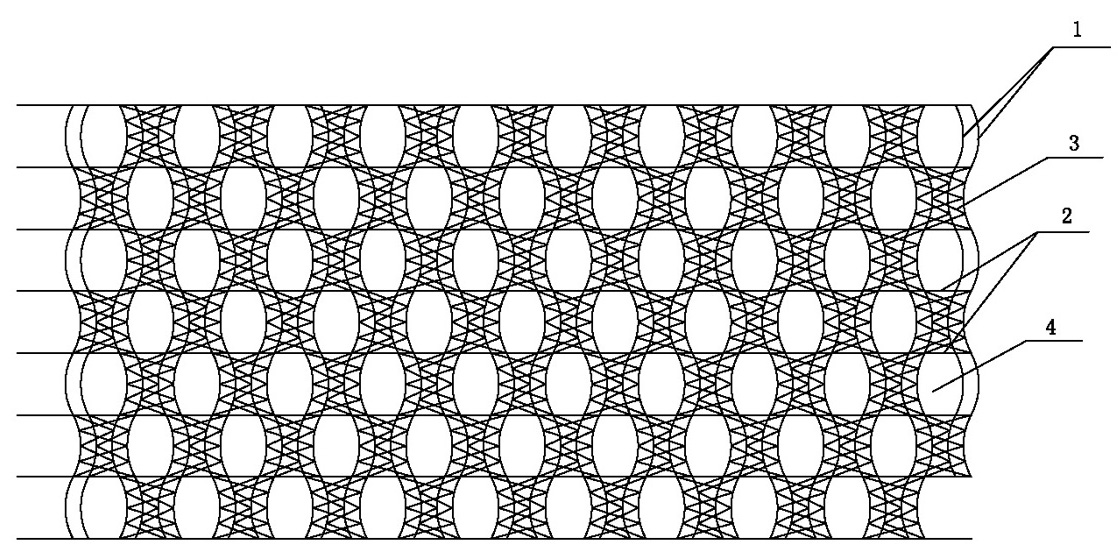

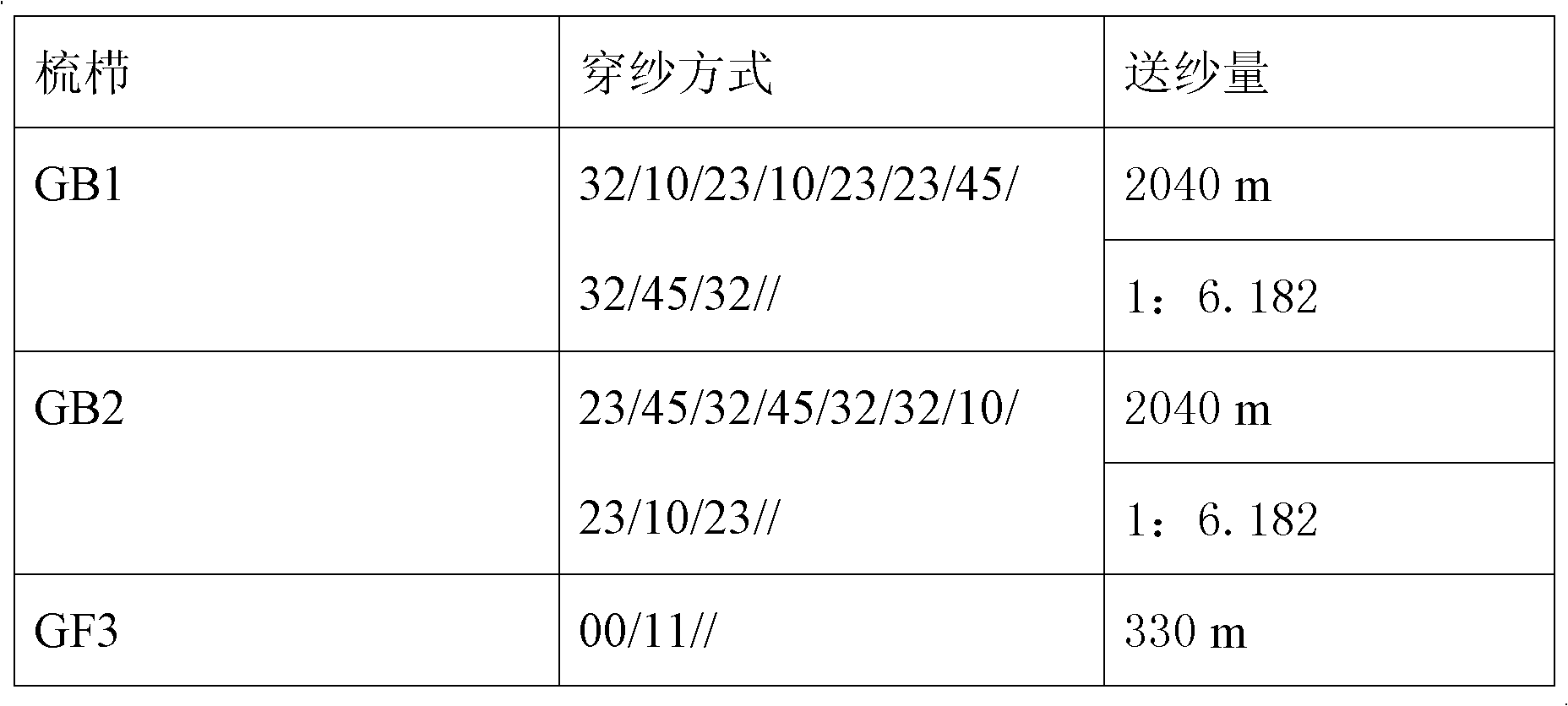

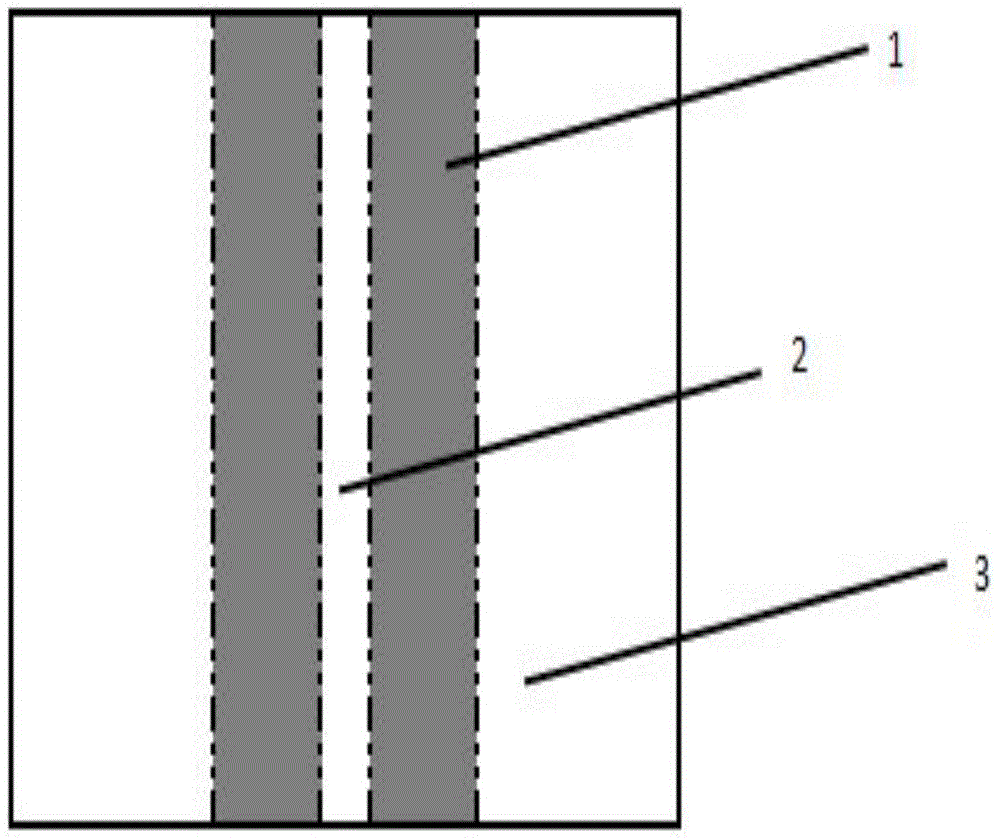

Warp knitted eyelet fabric capable of shielding microwave

InactiveCN102002807AOvercoming the prone phenomenon of latitudinal "train track"Overcome latitude "train track" phenomenonFibre typesWarp knittingPolyesterMicrowave

The invention relates to a warp knitted eyelet fabric capable of shielding microwave. The warp knitted eyelet fabric is prepared by the following steps: weaving with warp yarn, weft yarn and binding yarn by a warp knitting weaving process, dyeing, shaping and coiling to obtain the product, wherein, the warp yarn is 30S / 2-50S / 2 polyester acrylic blended conductive yarn, the weft yarn is combination of 30S / 2-50S / 2 polyester acrylic blended conductive yarn and 500D-1000D high-strength low-shrinkage polyester drawn yarn, the binding yarn is 50D-200D polyester drawn yarn and the warp knitted eyelet fabric capable of shielding the microwave is integrally in a honeycomb shape composed of a plurality of meshes. The warp knitted eyelet fabric capable of shielding the microwave can be used for solving the defects of poor fixing performance, high possibility of displacement, poor pattern regularity and the like of a low-density warp knitting material, and has the advantages of high fixing performance, regular grids and less possibility of displacement; and the shielding efficiency of frequency segments reaches 20dB and energy attenuation reaches over 98%, thus meeting the protection demand of people on the microwave.

Owner:ZHEJIANG GAODA NEW MATERIAL

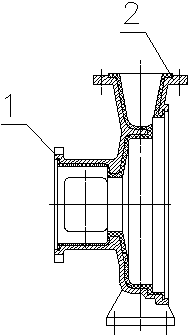

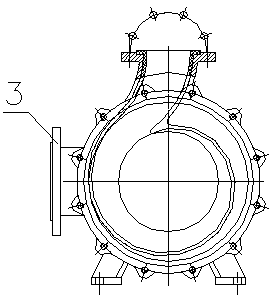

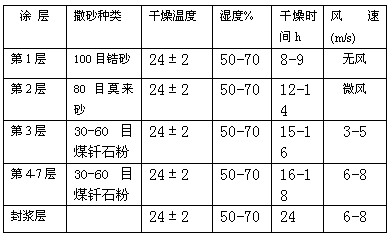

Casting method of centrifugal pump body

InactiveCN103506582AEasy to processImprove casting qualityFoundry mouldsFoundry coresWaxInjection pressure

A casting method of a centrifugal pump body comprises the following steps of: 1) urea core fabrication: mixing urea and white granulated sugar strictly at a mass ratio of 100:6, heating to 140-160 DEG C, injecting into a cavity after melting, taking out the urea core for inspection after cooling, allowing the urea core to be white and free from any open defects on the surface, 2) wax mold fabrication: controlling wax pressing temperature to be 55-62 DEG C, injection pressure to be 0.8-1.0MPa, injection time to be 50s, and dwell time to be 10min, allowing the surfaces of a wax mold and the cavity to be smooth, clean and free from cracks, 3) pouring system design: taking feeder head top pouring mode as an injection mode and adopting a crossed assembly welding mold head, 4) shell fabrication: adopting a silicasol technology and referring to Figure 3 for shell fabrication parameters in order to ensure shell strength and roughness of a cast surface, and 5) shell roasting and pouring: allowing the roasting temperature to be 1080-1000 DEG C and roasting time to be 1h. The method facilitates processing, improves the casting quality, and does not produce defects such as shrinkage cavities and slag inclusion.

Owner:JIANGSU XINYUE PUMP IND MFG

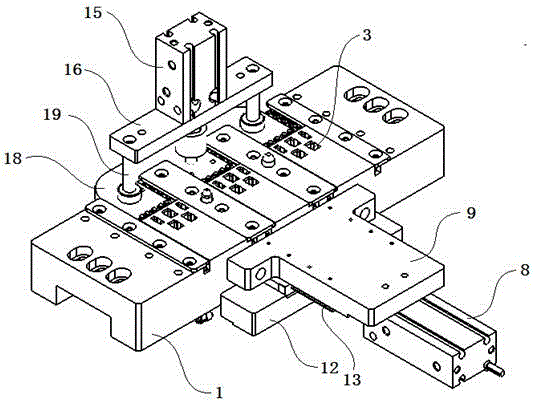

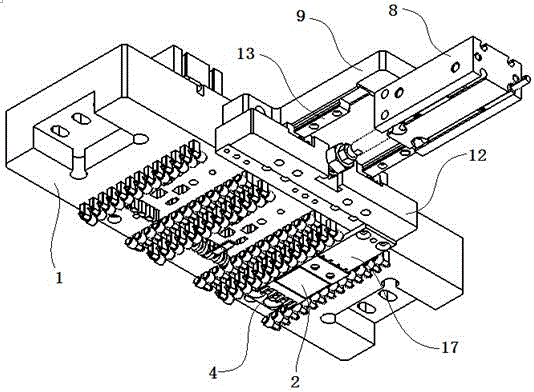

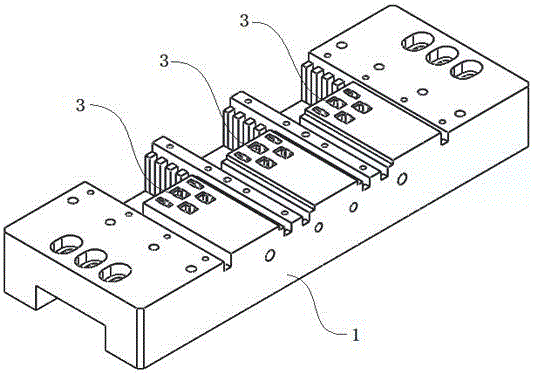

Magnet poking mechanism used for magnet assembling mechanism

ActiveCN106043763AHigh degree of automationImprove efficiencyIndividual articlesMagnetic polesEngineering

The invention discloses a magnet poking mechanism used for a magnet assembling mechanism. The magnet poking mechanism consists of a separating table, a separating plate, a horizontal pushing device and a vertical pressing device, wherein magnets fall off via magnet runners of the separating table; when the magnets fall to the bottoms of the magnet separating runners of the separating table, the magnets are pushed to the deep parts of the magnet separating runners under the action of a cylinder of the horizontal pushing device; and the magnets are pushed into a tray from magnet outlets by a cylinder of the vertical pressing device. The magnet poking mechanism is high in automation degree and high in efficiency, is stable and safe, can effectively replace manual work, is low in cost, is favorable to being applied to the processing of various electronic industries, and has incompatible advantages over a traditional manual arrangement method. The magnet poking mechanism can ensure that the same magnetic poles are placed towards the same directions, is high in accuracy, does not need manual work, can automatically separate and arrange various dimensions of magnets in the tray in order, spends about 50s in assembling one tray of magnets (about 300 pieces), is very high in efficiency, and has advantages over the existing mechanisms on the market in the aspects of automatic positioning and precision.

Owner:苏州茂特斯自动化设备有限公司

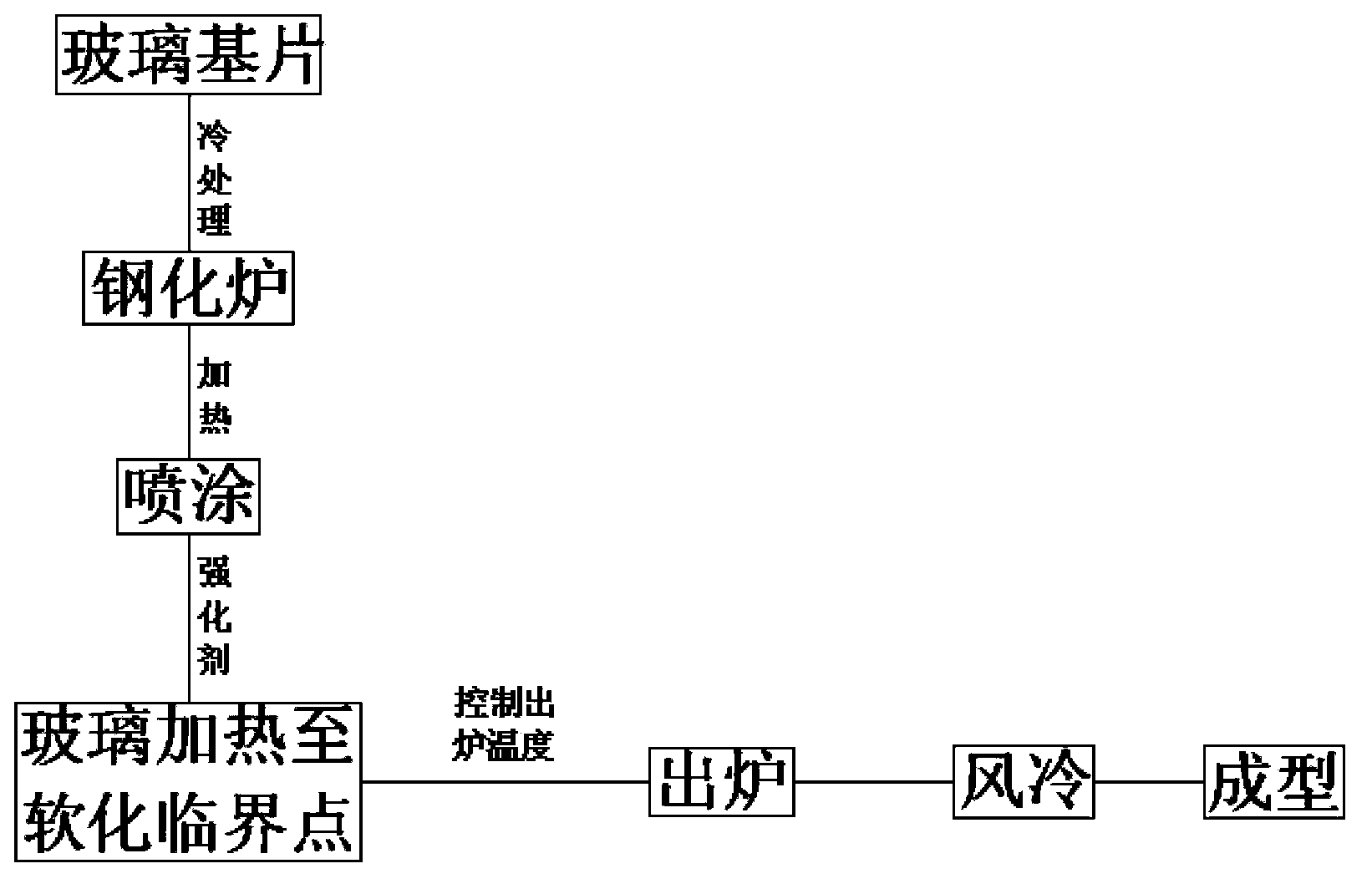

Preparation method of high-strength fireproof glass

InactiveCN103833200AHigh melting temperatureGood chemical stabilityGlass tempering apparatusCold treatmentHeating time

The invention discloses a preparation method of high-strength fireproof glass. The preparation method comprises following steps: float glass is taken as a substrate, and is subjected to cold treatment including edge polishing, circular corner polishing, and cleaning; the treated float glass is delivered into a toughening furnace for heat treatment, wherein the treated float glass is heated to 700 to 720 DEG C, heating time is 50S / mm, spraying of a reinforce is carried in the heating process, and the treated float glass is heated to softening critical states; a temperature sensor is used for controlling a discharging temperature to be 700 to 710 DEG C; the glass which is heated to the softening critical states is delivered into an air cooling device with a speed of 200mm / s-300mm / s, upper air pressure of the air cooling device is controlled to be 680 to 700kPa, and lower air pressure is controlled to be 640 to 660kPa. According to the preparation method, spraying of the reinforce in the high-temperature heating process is adopted, so that the obtained glass possesses fire resistance, and strength of the glass is more than 5 times of original strength of the glass; the preparation method is simple and convenient; production cost is reduced; and pollution on the environment is reduced.

Owner:虞建忠

Technique for cleaning diesel engine cylinder block

InactiveCN106272091AImprove quality and efficiencyImprove cleaning efficiencyLiquid surface applicatorsRevolution surface grinding machinesWorking environmentCylinder block

A technique for cleaning a diesel engine cylinder block includes the following steps that a gas outlet needle of the diesel engine cylinder block to be processed is removed, the residual root of the gas outlet needle is shorter than 10 mm, burnt-on sand in an inner cavity of the diesel engine cylinder block is removed through core hitting, and the core hitting time is 35-50s; the diesel engine cylinder block is placed in a shot blasting machine to be subjected to primary shot blasting and secondary shot blasting; manual shot blasting is carried out after secondary shot blasting; sand on the diesel engine cylinder block is blown by gas after manual shot blasting, and residual powder grains on the surface are removed; and high-temperature antirust paint is sprayed, and the diesel engine cylinder block is checked and stored. According to the technique for cleaning the diesel engine cylinder block, manual shot blasting is carried out after secondary shot blasting in the shot blasting machine, so that shot blasting quality and cleaning efficiency of the diesel engine cylinder block are improved, and the shot blasting quality of the inner cavity of the diesel engine cylinder block is ensured; sand blowing is conducted after manual shot blasting, and then the high-temperature antirust paint is sprayed, so that the diesel engine cylinder block has excellent mechanical performance and is superior in chemical corrosion resistance such as acid resistance, alkali resistance and hot oil resistance; and according to the cleaning technique, dust pollution is lowered, and the working environment is improved.

Owner:HEFEI JAC CASTING

Processing method for nano-texture glass with high reflectivity

InactiveCN107698169AIncrease reflectionGood weather resistanceDecorative surface effectsCoatingsHigh reflectivityReflective layer

The invention discloses a method for processing high-reflectivity nano-textured glass, which comprises the steps of preprocessing, micro-structure layer texture processing and reflective layer processing. The micro-structure layer texture processing step includes: on tempered glass 200-300 mesh screen printing or spraying glass UV high-transparent ink layer, the coating thickness is 30-45μm; the glass and the template are pressed by roller pressing and pressing equipment, and the distance between the rollers is the total thickness of the glass and the template ‑0.3mm; pre-curing the UV high-transmittance ink layer on the glass at a temperature of 45~55℃, the pre-curing power is 5.6KW, the UV wavelength is 365nm, and the pre-curing time is 30S; mold release transfer; The high-permeability ink coating is completely cured, so that the nano-texture is cured on the glass surface, and the UV high-permeability ink layer on the glass is completely cured at a temperature of 45-55°C. The curing power is 11.2KW, the UV wavelength is 365nm, and the curing is 40-50S. The invention can embody the characteristics of small patterns, good processing quality and the like.

Owner:深圳市锦瑞新材料股份有限公司

Processing technology of aluminum substrate

InactiveCN104105348ADetailed processing stepsExtended service lifePrinted circuit manufactureAnodizingSolder mask

The invention discloses a processing technology of an aluminum substrate. The processing technology comprises the following concrete steps of cutting, removing surface oil, anodizing, cleaning, drying, applying a coupling agent, drying, laminating, trimming, performing primary drilling, printing a wet film, performing primary preliminary drying, performing primary exposure, performing primary development, etching, removing the film, printing solder mask white oil, performing secondary preliminary drying, performing secondary exposure, performing second development, performing secondary drilling, cleaning the substrate subjected to the secondary drilling with an acid cleaning solution in an ultrasonic cleaner for 40-50s, taking out, washing, cooling, drying with 81-85 DEG C hot air, pasting a medium-viscosity protective film on a circuit surface with a hot pressing roller, performing numerically-controlled drilling and milling for shaping, inspecting and shipping. The processing technology has the advantages that the technology is mature, and the service life of a finished product is long.

Owner:张龙

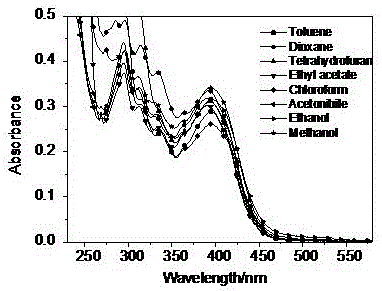

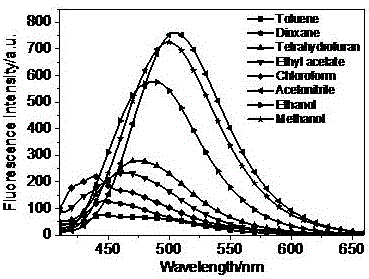

Carbazole-contained benzimidazole-substituted quinoline derivative, preparation method and application thereof

ActiveCN105968098AImprove complexation effectQuick responseOrganic chemistryFluorescence/phosphorescenceQuinolineSolvent

The invention belongs to the technical field of analytical chemistry, and in particular relates to a carbazole-contained benzimidazole-substituted quinoline derivative, a preparation method and an application thereof. The carbazole-contained benzimidazole-substituted quinoline derivative is 3-(2-(8-(1H-benzo[d] imidazole-2-yl) quinoline-2-yl) ethenyl)-9-benzyl-9H-carbazole. The preparation method includes the steps of placing 2-methyl-8-(1H-benzimidazole) quinoline and 9-benzyl-9H-carbazole-3-formaldehyde into polar solvents, adding catalysts, stirring and performing backflow reaction; performing purification after the backflow reaction to obtain a target compound carbazole and benzimidazole-substituted quinoline derivative L. A benzimidazole quinoline derivative zinc ion fluorescent probe is excellent in complexing action with zinc ions and rapid in response, the response time of the Zn<2+>fluorescent probe for Zn<2+> is 50s, the lowest detection limit is 6.69*10-8mol / L, and the fluorescent probe can be used for quantitative trace detection of the zinc ions by fluorescence spectrophotometry.

Owner:CHINA THREE GORGES UNIV

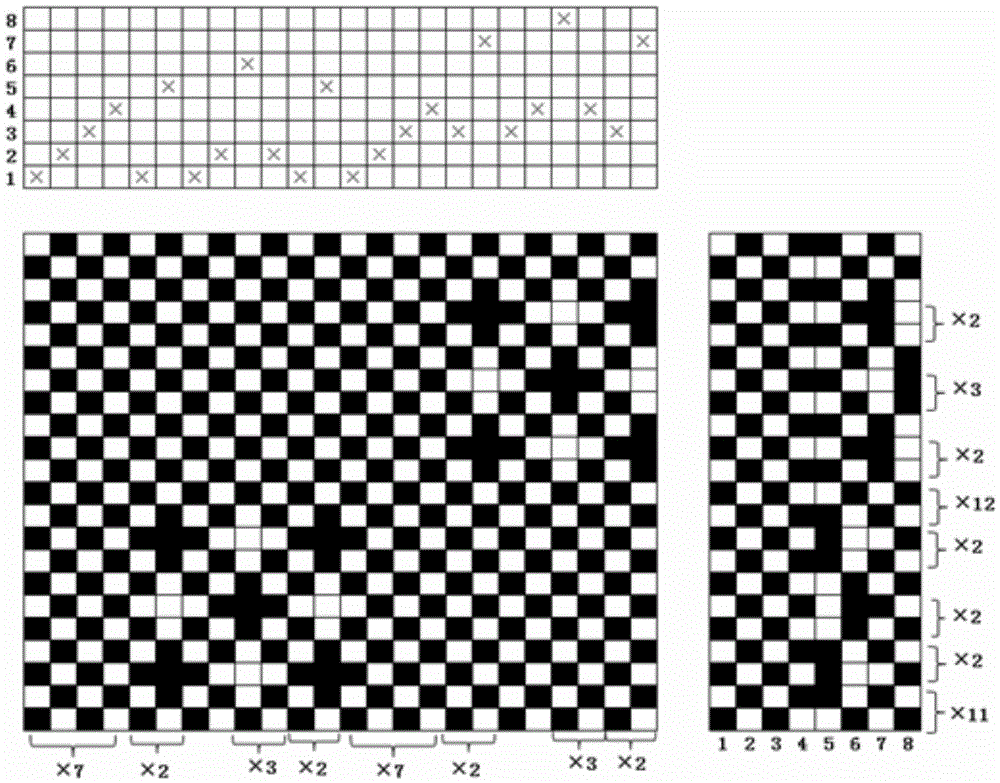

Chemical fiber/cotton blended colored woven fabric and weaving process thereof

The invention discloses a chemical fiber / cotton blended colored woven fabric which is interweaved by warps and wefts. The fabric is in 1 / 1 plain weave; the warps include four raw materials of rose 50S ecological cotton, brown 50S ecological cotton, white 50S ecological cotton and sea blue 50S ecological cotton; the wefts also include four raw materials of pink 70D / 40D brocade / spandex, green 70D / 40D brocade / spandex, white 70D / 40D brocade / spandex and dark green 70D / 40D brocade / spandex; the warp density of the fabric is 175 / ft. and the weft density of the fabric is 90 / ft. The chemical fiber / cotton blended colored woven fabric provided by the invention has the following technical effects of soft handfeeling of the fabric, clear and good-looking patterns, mild luster, bright color, simple and easy weaving process, high production efficiency and low cost.

Owner:HAIAN LIANFA ZHANGSHI YARN DYED

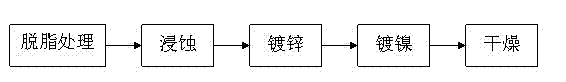

Surface treatment method for aluminum alloy

InactiveCN102877043AImprove uniformityHigh hardnessLiquid/solution decomposition chemical coatingNickel saltRoom temperature

The invention provides a surface treatment method for aluminum alloy. The method comprises the following steps of: 1) degreasing, namely dipping absorbent cotton in solvent, and wiping the surface of the aluminum alloy to remove greasy dirt on the surface; 2) etching, namely etching the degreased aluminum alloy in an etching solution and etching to remove an oxide film on the surface of the aluminum alloy, and washing and drying; 3) plating zinc, namely immersing the etched aluminum alloy in a zinc plating solution, keeping at the room temperature for 40 to 50s, washing, dipping in a stripping solution for 1 minute, washing and drying; 4) plating nickel, namely dipping the aluminum alloy on which zinc is plated in a nickel salt solution and controlling the temperature of the nickel salt solution to be 90 DEG C; and 5) drying. By the mode, the plating layer with high uniformity can be obtained, is high in hardness and brittleness, high in wear resistance and corrosion resistance, and is smooth and easy to braze.

Owner:昆山市源丰铝业有限公司

Preparation method for high-performance stamping cold-rolled and galvanized steel strip

InactiveCN104946971AGuaranteed concentrationGuaranteed processing performanceHot-dipping/immersion processesChemical compositionStrip steel

The invention discloses a preparation method for a high-performance stamping cold-rolled and galvanized steel strip. The preparation method is characterized in that the steel strip comprises the following chemical components in percentage by mass: 0.01-0.06% of C, 0.10-0.50% of Mn, less than or equal to 0.020% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Si, greater than or equal to 0.020% of Als, greater than or equal to 0.0040% of N, and the balance of Fe and impurities within a permissible range. The method comprises a holt rolling process, a cold rolling process and a galvanizing process, wherein in the hot rolling process, a heating temperature of steel billet is 1100-1200 DEG C, the heat preservation is carried out for 1-2 hours, and a final-rolling temperature is 890-910 DEG C; a cooling mode adopts a front-stage cooling mode, and a rolling temperature is 670-700 DEG C; in the galvanizing process, the heating temperature of the strip steel is 760-830 DEG C, the soaking temperature is 760-810 DEG C, an annealing cooling rate is greater than or equal to 20 DEG C / s, and the strip steel is added into a zinc pot when being cooled to 460-490 DEG C; and during cooling after plating, overaging time of the strip steel is guaranteed to be greater than or equal to 50s. According to the preparation method disclosed by the invention, the stamping surface and the applicability in various purposes of a product are greatly improved; and the product is guaranteed to be prevented from stamping problems such as transverse grains and the like in a processing and forming process.

Owner:TANGSHAN IRON & STEEL GROUP

High-blackness high-brightness black master batch and preparation method thereof

The invention relates to high-blackness high-brightness black master batch and a preparation method thereof. The high-blackness high-brightness black master batch comprises the following ingredients by weight: 50 percent of carbon black BP717, 14.2 percent of low-density polyethylene LDPE-1C7A, 19.09 percent of linear low-density polyethylene LLDPE-2650, 11.54 percent of polyethylene wax AC-6A, 4.67 percent of lubricant wax H-50S, and 0.5 percent of an antioxygen AO-50. The preparation method comprises the following processes: stirring, mixing, granulating, dewatering and packing. Compared with the prior art, the high-blackness high-brightness black master batch is low in impact on a plastic material to-be-modified, and easy to dilute in a plastic product, and has the advantages of high blackness, high blue phase, high brightness, and excellent dispersity, thereby having high popularization value.

Owner:茂康材料科技(常熟)有限公司

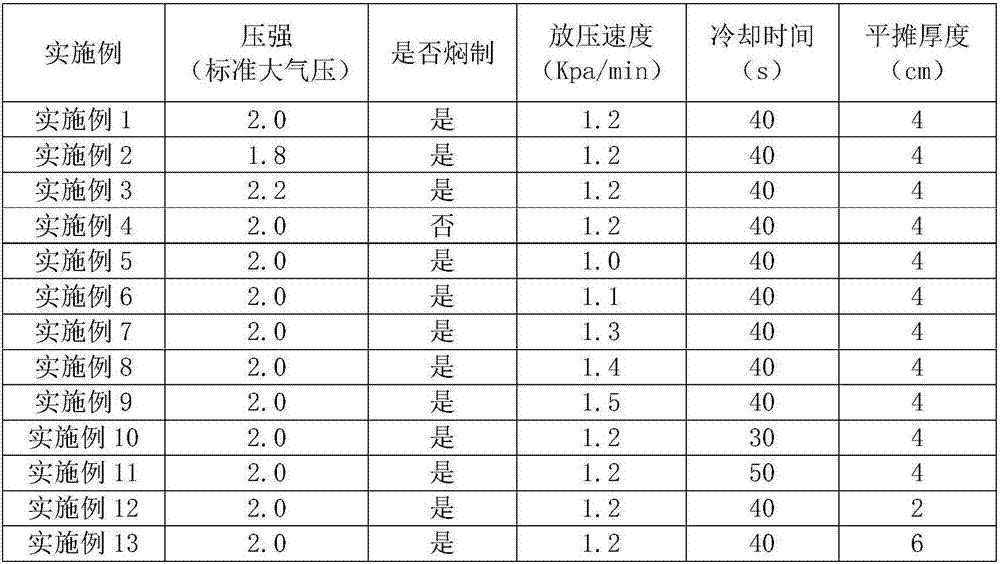

Tea drying process

InactiveCN107047823APrevent high temperature stuffinessWill not cause "dead bar" phenomenonPre-extraction tea treatmentCold airFree cooling

The invention relates to the field of agricultural product processing and discloses a tea drying process. The process comprises the following steps of: placing the black tea that is fermented for 4-6 hours in a sealed container and introducing nitrogen into the sealed container to increase the air pressure in the sealed container to 1.8-2.2 standard atmospheric pressure (atm); heating the sealed container to increase the temperature inside the sealed container to 110-120DEG C; releasing the nitrogen inside the sealed container slowly to decrease the air pressure at a speed of 1-1.5 Kpa / min until the air pressure inside the sealed container is decreased to the standard atmospheric pressure; introducing nitrogen of 0-5 DEG C into the sealed container and cooling the surface of the tea for 30-50s, then immediately taking out the cooled tea from the sealed container and spreading and cooling naturally; and spreading the tea in a drying shed and introducing cold air of 0-5 DEG C to the drying shed for carrying out air drying with the cold air completely until the moisture content of the tea is decreased to be 5% or below. Compared with the prior art, the tea drying process has the advantage that the tea has a stronger aroma and higher quality.

Owner:ZHENGAN COUNTY FUYAN TEA IND CO LTD

Method for rapid detection of SiO2 film thickness and film compact

InactiveCN104865178AQuick checkImprove test efficiencyWeather/light/corrosion resistanceProduction lineTest efficiency

The invention provides a method for rapid detection of SiO2 film thickness and film compact, and relates to the technical field of glass detection. The detection method is as follows: 1) preparing an acidic solution containing HF, HNO3 and DI water in a ratio of 2.4%:1.6%:96%, and storing the acidic solution in a plastic cup; 2) cutting a sample to be tested into small pieces, and attaching two parallel tapes with spacing of 1mm to the surface to form a step, compacting the tapes along the same direction and keeping the step edges smooth; 3) heating a water bath, setting the temperature to 30 DEG C, and heating the plastic cup filled with acidic solution in the water bath; and confirming the temperature of the acidic solution reaching 30+ / -2 DEG C; and 4) soaking the step into the acidic solution with specified temperature, and detecting the etching rate at the soak time of 50s, 70s, 90s and 110s. The method can directly use adverse glass in the production line in the production process for test again, does not need an oil pen line for production of sample steps, and greatly improves test efficiency and productivity.

Owner:安徽立光电子材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com