Tea drying process

A drying process and tea technology, applied in the direction of tea treatment before extraction, can solve the problems of difficult to tighten the tea sticks, the tea leaves are dry and wet inside, the coke is wet inside and so on, and the tea leaves can be fully stretched, the tea quality is high, and the aroma is full. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

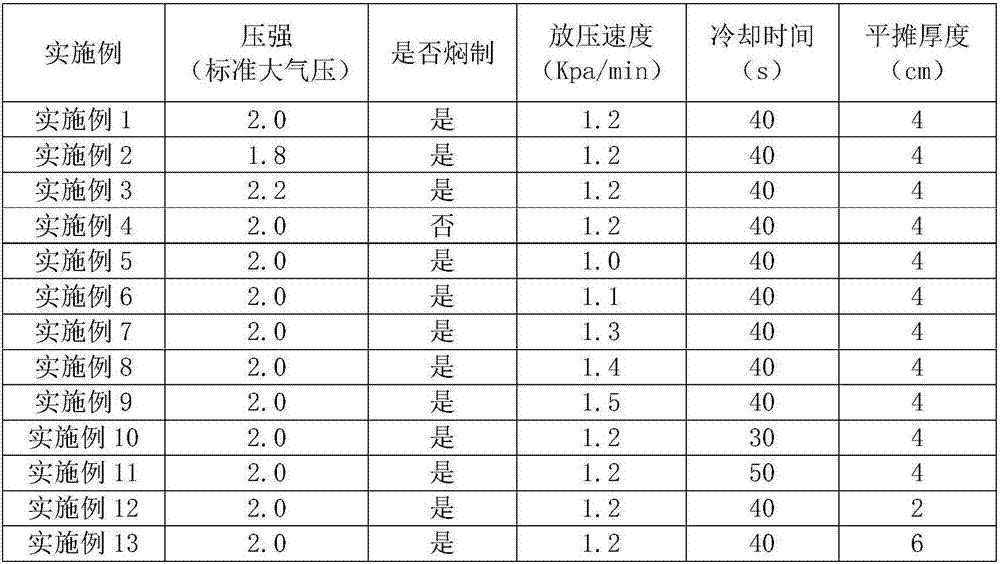

Examples

Embodiment 1

[0023] It includes the following steps:

[0024] Step 1: Place the tea leaves: Place the fermented black tea in a closed container, and fill the closed container with nitrogen so that the pressure in the closed container reaches 2.0 standard atmospheres;

[0025] Step 2. Preliminary drying: Heat the airtight container to make the temperature in the airtight container reach 115°C, stop heating, and simmer the tea leaves in the airtight container for 4 minutes, slowly release the nitrogen in the airtight container, and reduce the air pressure at a rate of 1.2Kpa / min until The air pressure in the closed container drops to standard atmospheric pressure;

[0026] Step 3. Secondary drying: Fill the airtight container with nitrogen at 2°C, cool the surface of the tea leaves for 40s, and then immediately take the tea leaves out of the airtight container, spread it out and cool it naturally;

[0027] Step 4. Completely dry: Spread the tea flatly in a drying room with a thickness of 4cm, blow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com