Surface treatment method for aluminum alloy

A technology of aluminum alloy surface and treatment method, which is applied in the field of aluminum alloy surface treatment, can solve the problems of unimproved wear resistance, poor ability to adapt to the environment, and uneven conversion film layer, etc., and achieve high brittleness, cost saving, and easy The effect of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

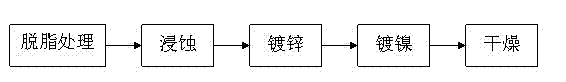

[0020] see figure 1 , the embodiment of the present invention includes:

[0021] A method for surface treatment of an aluminum alloy, comprising the steps of:

[0022] 1) Degreasing treatment: wipe the surface of aluminum alloy with absorbent cotton wetted with solvent to remove surface oil;

[0023] 2) Etching: Etching the degreased aluminum alloy in an etching solution to remove the oxide film on the surface of the aluminum alloy, then washing and drying;

[0024] 3) Galvanizing: immerse the etched aluminum alloy in the galvanizing solution, keep it at room temperature for 40-50s, wash with water and then dip in the stripping solution for 1mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com