Processing technology for single-sheet cesium potassium fireproof glass

A technology of fireproof glass and processing technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of unsatisfactory fireproof treatment temperature control range, affecting fireproof glass performance indicators, uneven heat source, etc., and achieve machinable Good performance, high weather resistance, wide application field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

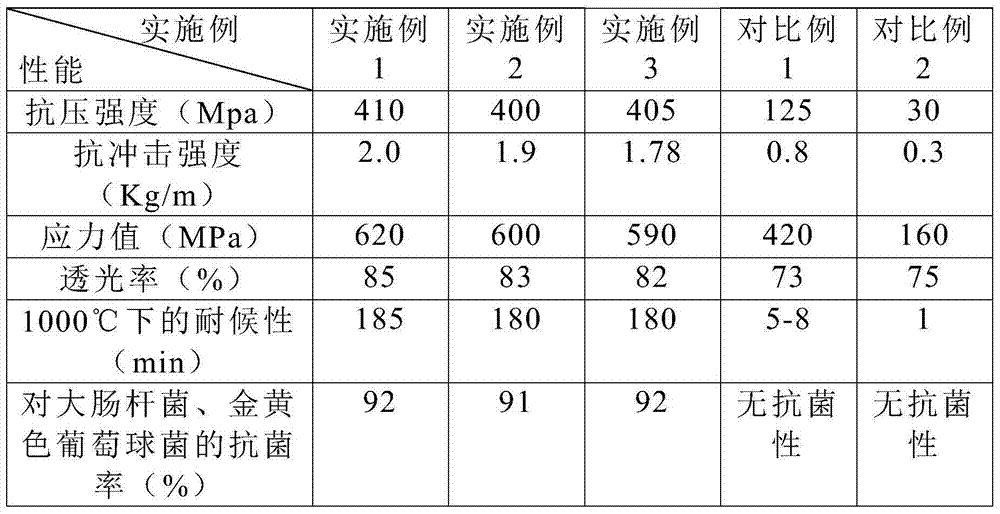

Examples

Embodiment 1

[0024] Glass pre-treatment: use 15% HF solution and 20% HNO 3 The acid solution mixed according to the volume ratio of 1.2:1 is used for acid treatment on the surface of the glass. The temperature of acid treatment is 18°C, and the time of acid treatment is 18min. Then the glass is cleaned and dried, preheated to 390°C, and kept warm. 28min;

[0025] Ion exchange treatment: immerse the preheated glass in cesium potassium salt solution at a temperature of 600°C for ion exchange treatment for 20 hours, wherein the composition and weight percentage of the cesium potassium salt solution in the ion exchange treatment are: AgNO 3 : 5%, KNO 3 : 88%, CsNO 3 : 4%, KOH: 0.4%, KCl: 0.3%, K 2 CO 3 : 0.8%, Al 2 o 3 : 0.2%, CeO 2 : 0.3%, diatomaceous earth: 1.0%;

[0026] Heat treatment: send the ion-exchange-treated glass into a tempering furnace for heat treatment, the heat treatment temperature is 700°C, and the heating time is 45s per mm thickness; the heating temperature at th...

Embodiment 2

[0029] Glass pre-treatment: use 10% HF solution and 25% HNO 3 The acid solution mixed according to the volume ratio of 1.5:1 is used for acid treatment on the surface of the glass. The temperature of acid treatment is 15°C, and the time of acid treatment is 20min. Then the glass is cleaned and dried, preheated to 400°C, and kept warm. 25min;

[0030] Ion exchange treatment: immerse the preheated glass in cesium potassium salt solution at a temperature of 650° C. for ion exchange treatment for 18 hours, wherein the composition and weight percentage of the cesium potassium salt solution in the ion exchange treatment are: AgNO 3 : 3%, KNO 3 : 90%, CsNO 3 : 3%, KOH: 0.2%, KCl: 0.4%, K 2 CO 3 : 1.5%, Al 2 o 3 : 0.2%, CeO 2 : 0.2%, diatomaceous earth: 1.5%;

[0031] Heat treatment: send the ion-exchange-treated glass into a tempering furnace for heat treatment, the heat treatment temperature is 690°C, and the heating time is 40s per mm thickness; the heating temperature at th...

Embodiment 3

[0034] Glass pre-treatment: use 20% HF solution and 15% HNO 3 The acid solution mixed according to the volume ratio of 0.8:1 is used to acid-treat the surface of the glass. The temperature of the acid treatment is 20°C, and the acid treatment time is 16 minutes. Then the glass is cleaned and dried, preheated to 380°C, and kept warm. 30min;

[0035] Ion exchange treatment: immerse the preheated glass in a cesium potassium salt solution at a temperature of 550° C. for ion exchange treatment for 22 hours, wherein the composition and weight percentage of the cesium potassium salt solution in the ion exchange treatment are: AgNO 3 : 8%, KNO 3 : 85%, CsNO 3 : 2%, KOH: 0.5%, KCl: 0.4%, K 2 CO 3 : 0.6%, Al 2 o 3 : 1%, CeO 2 : 0.5%, diatomaceous earth: 2.0%;

[0036] Heat treatment: Send the ion-exchange-treated glass into a tempering furnace for heat treatment. The heat treatment temperature is 710°C, and the heating time is 50s per mm thickness; the heating temperature at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com