Fireproof door core plate material and preparation process thereof

A fire door core board and raw material technology, which is applied to fire doors, door leaves, windows/doors, etc., can solve the problems of unguaranteed active ingredients, affecting fire performance, and poor workmanship, so as to achieve controllable final setting time and improve use efficiency , the quality is easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

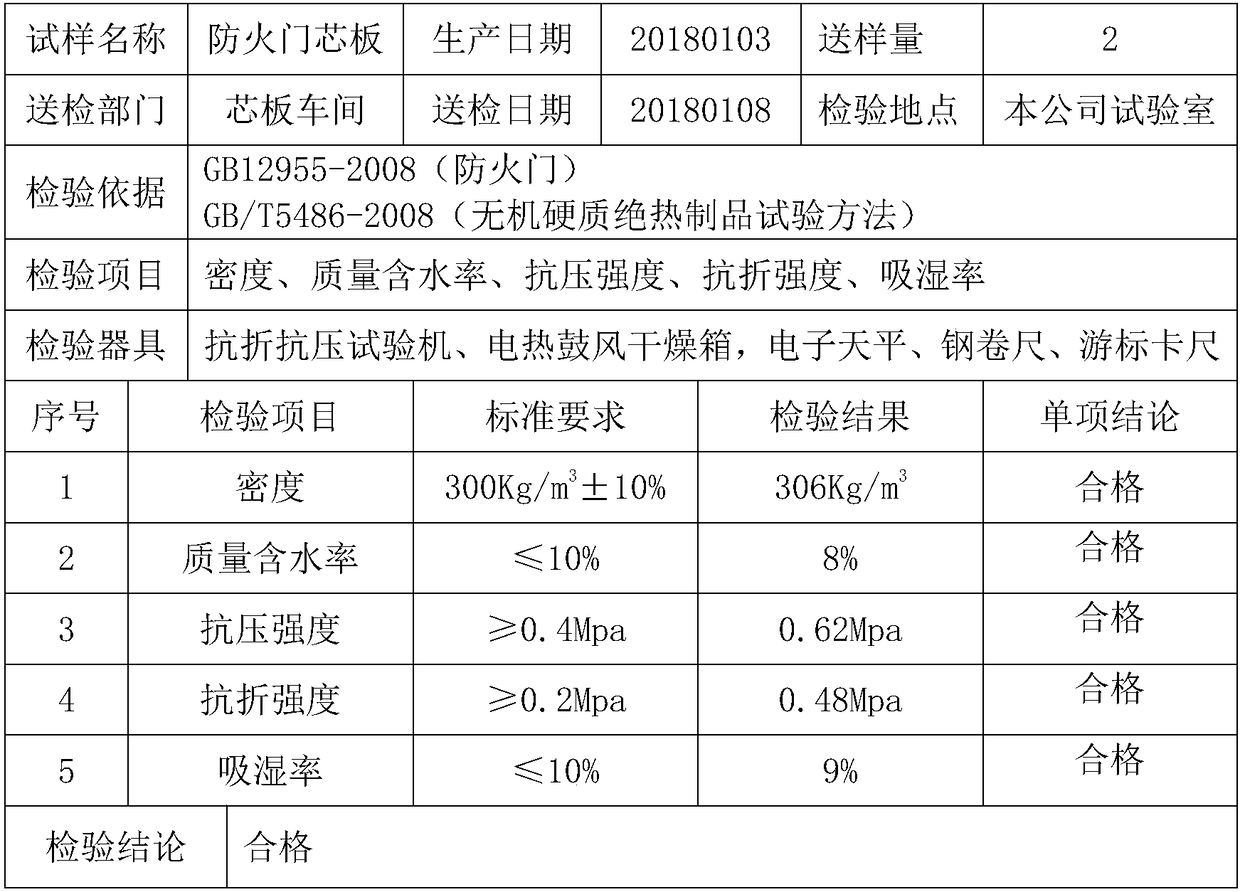

[0023] Fire door core board material, including the following raw materials: α-type high-strength gypsum 300Kg, tertiary vinegar emulsion 6Kg, polyvinyl alcohol 24880.2Kg, gypsum retarder 0.05Kg, foaming agent aqueous solution 40Kg, glass fiber with a length of 3cm 0.5Kg, water 100Kg, the weight ratio of foaming agent and water in the foaming agent aqueous solution is 1:70.

[0024] The preparation process is as follows: add water to the mixer, add α-type high-strength gypsum under stirring state, after stirring for 4 minutes, add tertiary vinegar emulsion, polyvinyl alcohol 2488, gypsum retarder and glass fiber, control the speed of the mixer to 30r / min, stir for another 3 minutes, beat the blowing agent into foam and add it to the mixer, control the speed of the mixer to 20r / min, and stir for 4 minutes.

Embodiment 2

[0026] Fire door core board materials, including the following raw materials: α-type high-strength gypsum 400Kg, tertiary vinegar emulsion 3Kg, polyvinyl alcohol 17881Kg, gypsum retarder 0.1Kg, foaming agent aqueous solution 20Kg, glass fiber with a length of 5cm 2Kg, water 140Kg, The weight ratio of foaming agent to water in the foaming agent aqueous solution is 1:90.

[0027] The preparation process is as follows: add water to the mixer, add α-type high-strength gypsum under stirring state, and after stirring for 6 minutes, add tertiary vinegar emulsion, polyvinyl alcohol 1788, gypsum retarder and glass fiber, and control the speed of the mixer to 50r / min, stir for another 5 minutes, beat the blowing agent into foam and add it to the mixer, control the speed of the mixer to 30r / min, and stir for 6 minutes.

Embodiment 3

[0029] Fire door core board material, including the following raw materials: α-type high-strength gypsum 350Kg, tertiary vinegar emulsion 4.5Kg, polyvinyl alcohol 2499 0.6Kg, gypsum retarder 0.08Kg, foaming agent aqueous solution 30Kg, glass fiber with a length of 4cm 1.3Kg , 120Kg of water, the weight ratio of foaming agent and water in the foaming agent aqueous solution is 1:80.

[0030] The preparation process is as follows: add water to the mixer, add α-type high-strength gypsum under stirring state, after stirring for 5 minutes, add tertiary vinegar emulsion, polyvinyl alcohol 2499, gypsum retarder and glass fiber, control the speed of the mixer to 40r / min, stir for another 4 minutes, beat the blowing agent into foam and add it to the agitator, control the speed of the agitator to 25r / min, and stir for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com