Low-temperature crystallization method of ammonium polyvanadate

An ammonium polyvanadate and low-temperature crystallization technology is applied in the field of vanadium precipitation, which can solve the problems of increasing the subsequent wastewater treatment pressure, increasing the output of vanadium precipitation wastewater, and demanding process parameters, and reducing the output of vanadium precipitation wastewater. , Reducing energy consumption such as steam, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

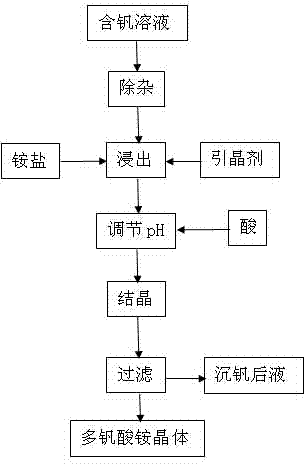

Image

Examples

Embodiment 1

[0046] Example 1: Taking the sodiumized roasting water leachate (containing vanadium solution, V=24.5g / l) of vanadium slag in a certain area of Chengde as an example, the specific process of the low-temperature crystallization method of ammonium polyvanadate is as follows.

[0047] (1) Add aluminum sulfate and magnesium chloride to the vanadium-containing solution, stir and react at 50°C for 1 hour, and then filter; the amount of aluminum sulfate added is: aluminum in the aluminum salt: silicon in the vanadium-containing solution = 1.5:1 (mol), and magnesium chloride is added Quantity: Dosed according to magnesium in magnesium salt: phosphorus in vanadium-containing solution = 1.2:1 (mol).

[0048] (2) Add ammonium sulfate, ammonium sulfate: vanadium element in the solution = 1.1:1 (mass).

[0049] (3) Add the seeding agent piperazine, the added mass is 10% of the mass of the ammonium salt, and keep stirring until it is completely dissolved.

[0050] (4) Add sulfuric acid to adjust ...

Embodiment 2

[0053] Example 2: Taking the stone coal acid leaching solution (a solution containing vanadium, V=45.6g / l) in a certain area of Hunan as an example, the specific process of the method for crystallization of ammonium polyvanadate at low temperature is as follows.

[0054] (1) Add aluminum chloride and magnesium nitrate to the vanadium-containing solution, stir and react at 80°C for 0.5h, and then filter; the amount of aluminum chloride added: aluminum in the aluminum salt: silicon in the vanadium-containing solution = 1.5:1 (mol) , The amount of magnesium nitrate added: add magnesium in magnesium salt: phosphorus in vanadium-containing solution = 1.2:1 (mol).

[0055] (2) Add ammonium chloride to the vanadium-containing solution, ammonium chloride: vanadium element in the solution = 0.8:1 (mass).

[0056] (3) Add the seeding agent ethylenediamine, the added mass is 5% of the mass of the vanadium element in the solution, and keep stirring until it is completely dissolved.

[0057] (4)...

Embodiment 3

[0060] Example 3: Taking a vanadium slag calcification roasting acid leaching solution (a solution containing vanadium, V=32.1 g / l) in a certain area of Sichuan as an example, the specific process of the method for crystallization of ammonium polyvanadate at low temperature is as follows.

[0061] (1) Add aluminum nitrate and magnesium chloride to the vanadium-containing solution, stir and react at 60°C for 0.6h, and then filter; the amount of aluminum chloride added: according to aluminum in the aluminum salt: silicon in the vanadium-containing solution = 1.2:1 (mol), add nitric acid The amount of magnesium added: According to the magnesium in the magnesium salt: the phosphorus in the vanadium-containing solution = 1.0:1 (mol).

[0062] (2) Add ammonium nitrate to the vanadium-containing solution, ammonium nitrate: vanadium element in the solution = 0.9:1 (mass).

[0063] (3) Add the seeding agent hexamethylenetetramine, the added mass is 20% of the mass of the vanadium element in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com