Method of sealing in small spatial obstructs at entrance end of tin pot in product line float glass, and seal structure

A float glass and production line technology, applied in the field of float glass production, can solve the problems of lower production stability, lower glass quality, attenuation of pure nitrogen flow stiffness, etc. material reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

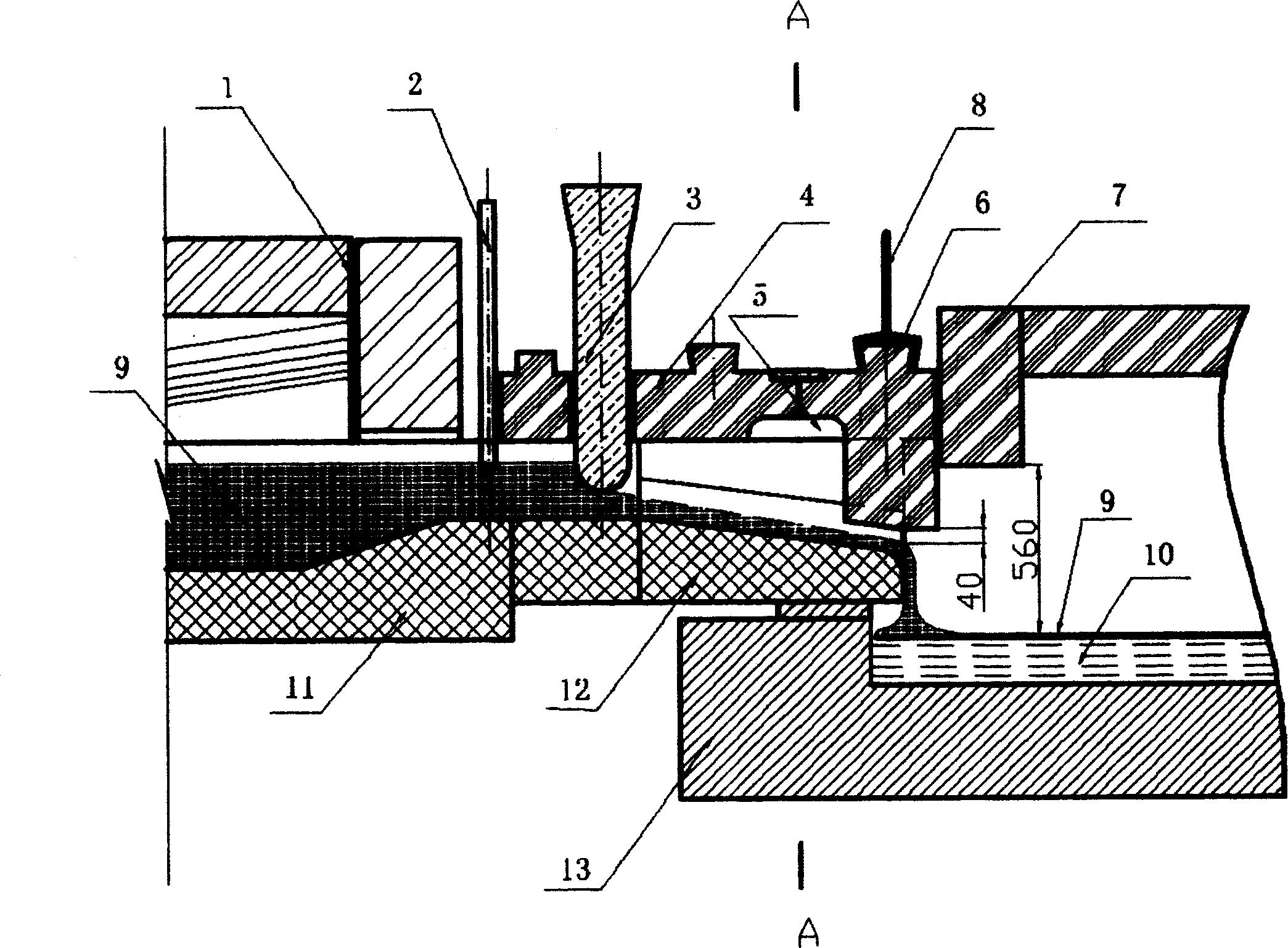

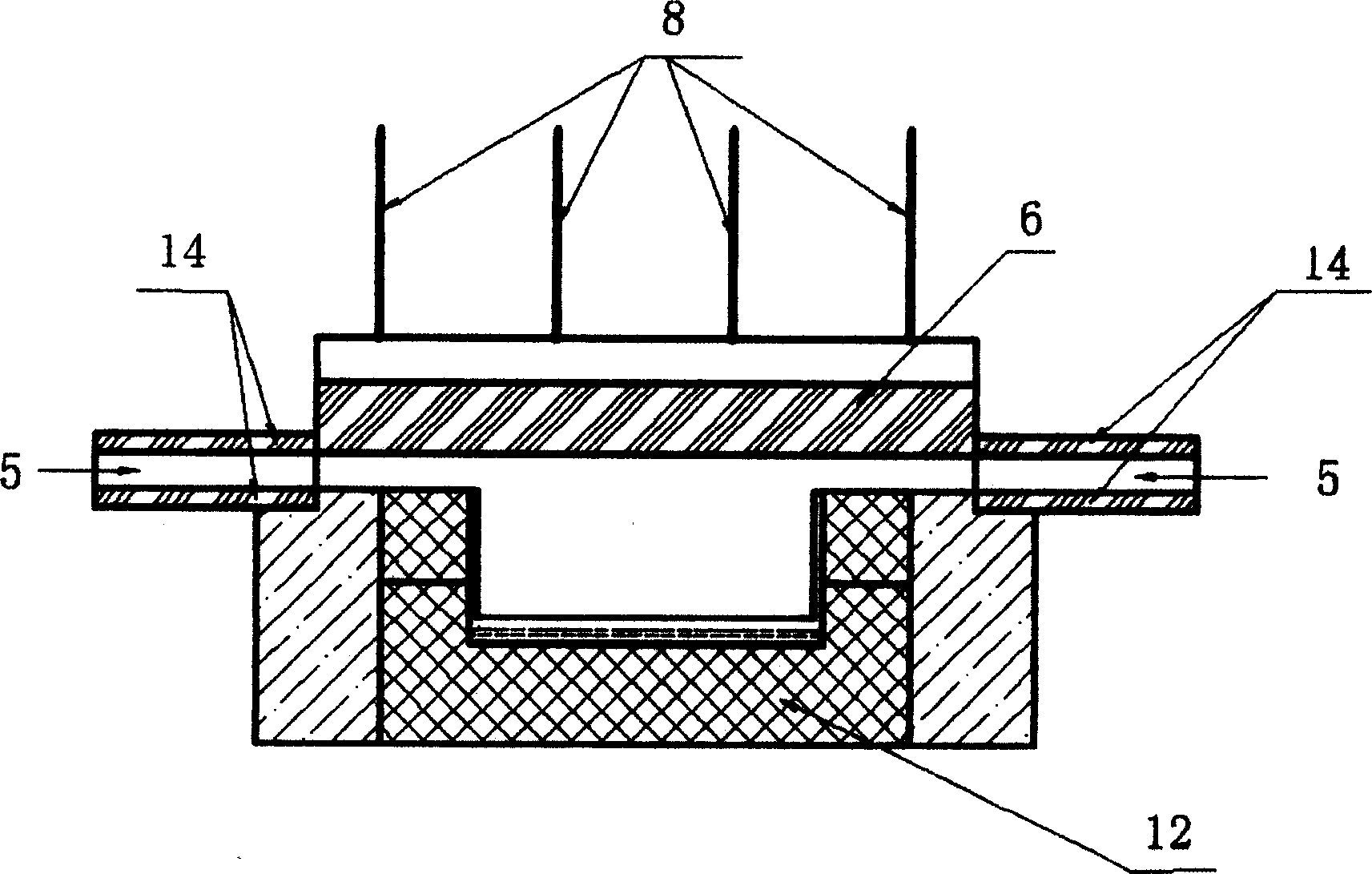

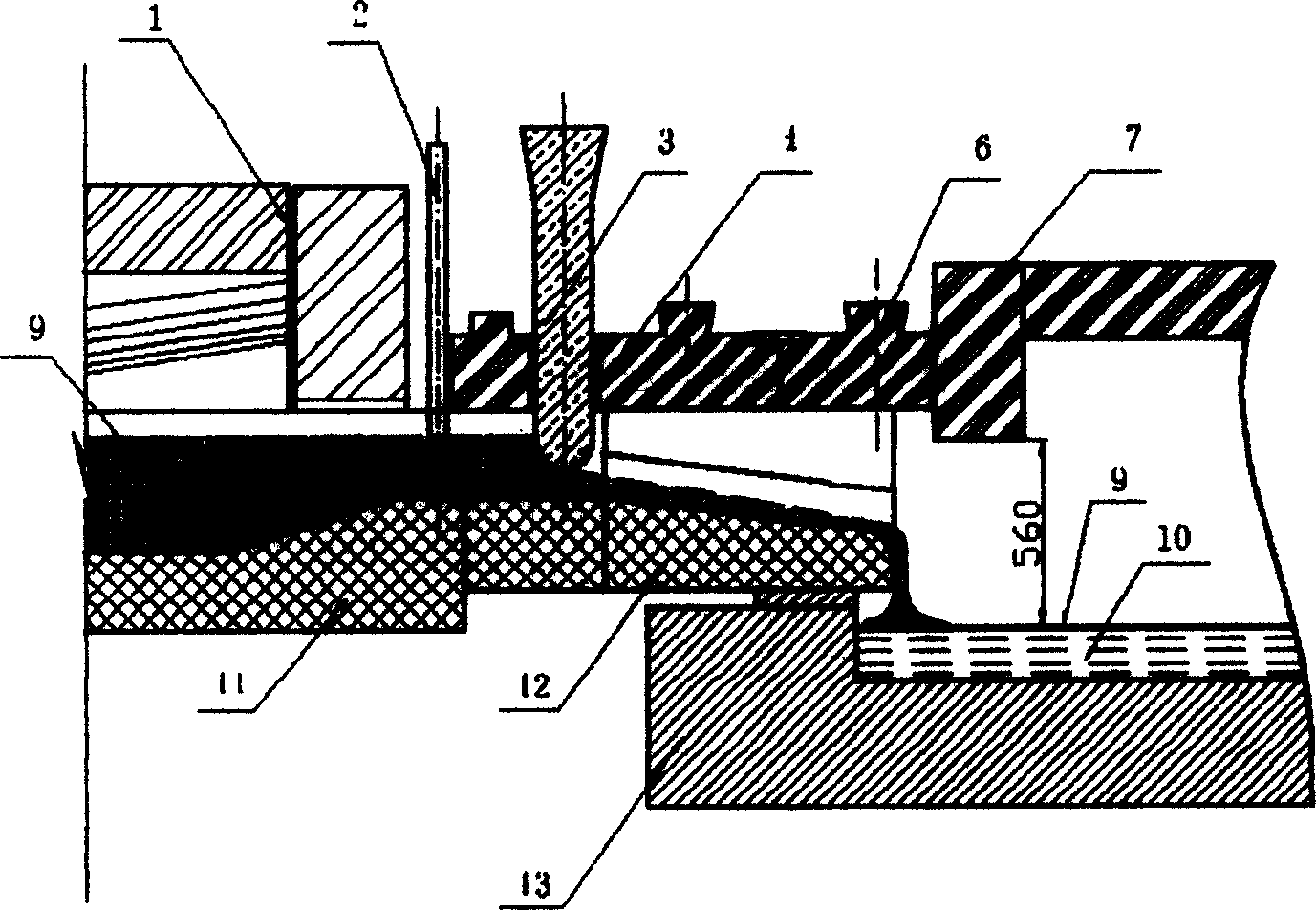

[0023] In conjunction with accompanying drawing, embodiment of the present invention is described as follows:

[0024] Such as figure 1 , 2 As shown, by setting a separation wall between the launder and the tin launder, a small air-permeable gap is formed between the tin ladle and the launder, and the upper part of the launder between the flow gate 3 and the separation wall 6 The space constitutes a closed space with only a small air gap. Nitrogen gas is introduced from both sides to the upper space between the flow gate and the separation wall. In this space, that is, the space above the launder, a pure nitrogen sealing area is formed. Taking a float glass production line with a melting capacity of 300 tons as an example, the amount of nitrogen introduced on each side is 15Bm 3 / h, the gas pressure of 50Pa can be formed in the upper space of the launder, which is greater than the pressure of the tin bath and the cooling part of the melting furnace, which can effectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com