Light partition wall board, and manufacture method and installation method thereof

A lightweight partition board, mixed material technology, applied in the direction of manufacturing tools, chemical instruments and methods, building structure, etc., can solve the problems of inconvenient installation and use, achieve good frost resistance and durability, and excellent responsiveness , The effect of good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In Embodiment 1 of the present invention, the lightweight partition wall board includes:

[0050] A pair of autoclaved asbestos-free construction cellulose construction fiber cement CCA boards;

[0051] An interlayer is arranged between the pair of pressure-steamed asbestos-free construction cellulose construction fiber cement CCA boards, and the interlayer is filled with a mixed material, and the mixed material includes: in parts by weight, 50-60 parts of Portland cement, 50-60 parts of ceramsite, 1-3 parts of construction fiber, 40-50 parts of water, 10-15 parts of straw fiber, and 0.5-1.2 parts of cement accelerator.

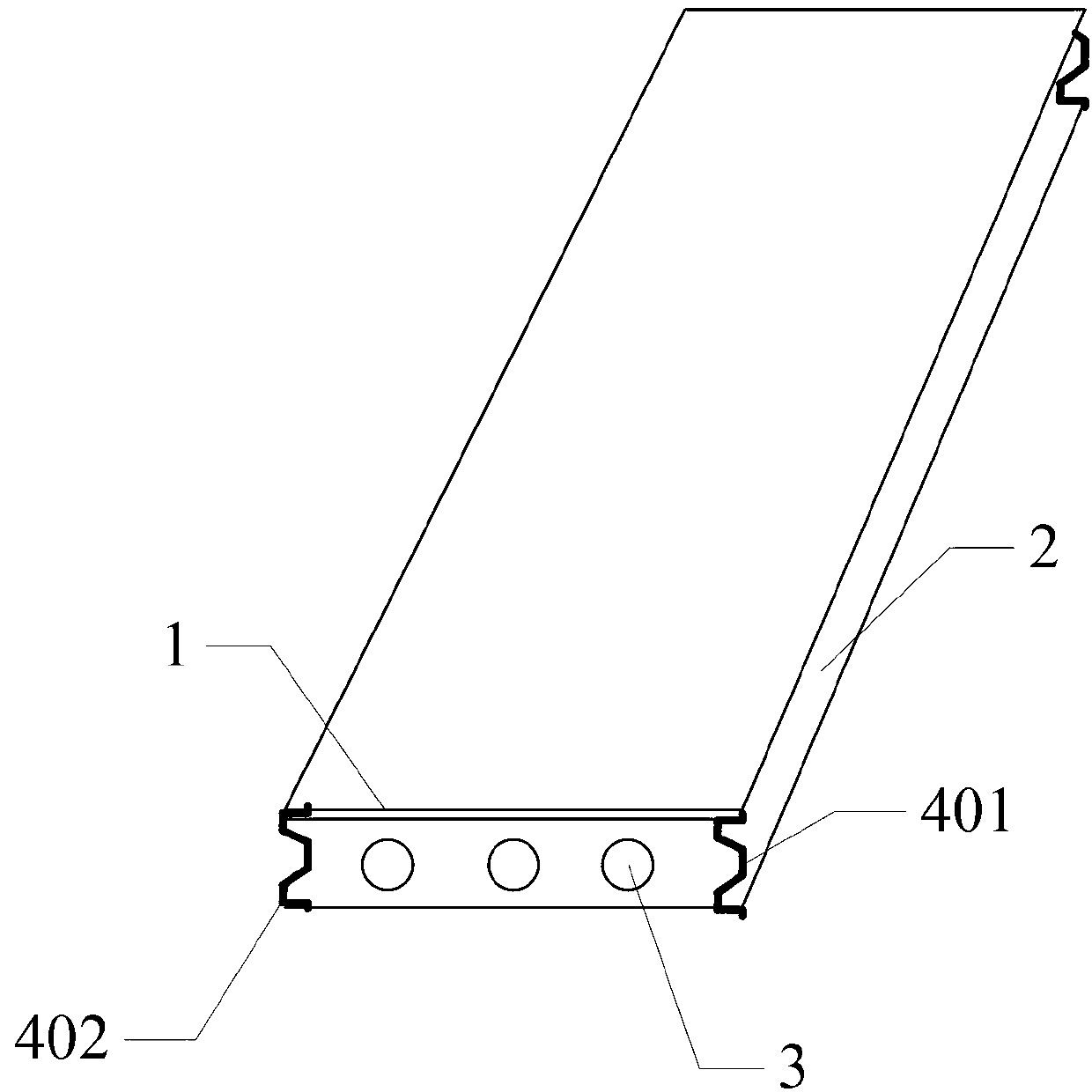

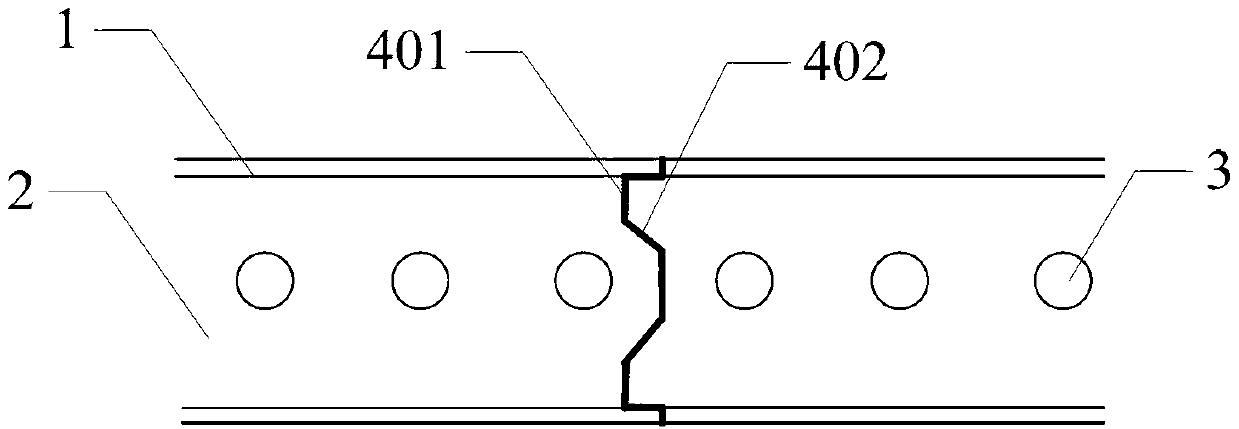

[0052] refer to figure 1, the lightweight partition wall board includes a pair of CCA boards 1, and an interlayer 2 of a mixed material is filled between the pair of CCA boards. The mixed material includes Portland cement, ceramsite, building fiber, water, straw fiber, and cement accelerator These materials are light inorganic materials, especially P...

Embodiment 2

[0065] In embodiment two, the manufacturing method includes:

[0066] Step 1: soaking the CCA board, the soaking time is 1-2 hours;

[0067] Step 2: In parts by weight, 50-60 parts of the Portland cement, 50-60 parts of the ceramsite, 1-3 parts of the construction fiber, 40-50 parts of the water, and the straw 10-15 parts of fibers and 0.5-1.2 parts of the cement coagulant are mixed and stirred to prepare the mixed material;

[0068] Step 3: pouring the mixed material between a pair of CCA plates;

[0069] Step 4: After the initial setting of the mixed material, the pair of CCA boards poured with the mixed material are cured.

[0070] The first step is to humidify the CCA board to increase the humidity of the CCA board so that the CCA board can better contact the poured mixed material, and after the mixed material condenses, the CCA board and the mixed material can be better integrated.

[0071] The second step is to prepare the mixed material poured between the CCA boards,...

Embodiment 3

[0078] In the third embodiment of the present invention, the installation method of the lightweight partition board includes:

[0079] Step 1: Carry out infrared rays at the installation position to draw fixed position control points;

[0080] Step 2: Install a U-shaped key at the side wall of the installation position and / or the fixed position control point of the column, and fix the lightweight partition board in the slot of the U-shaped key; Wherein, the lightweight partition wall board is placed sideways in the vertical direction; wherein, the interface structure is one side of the lightweight partition wall board that is sunken to the inside of the lightweight partition wall board and the load-bearing Wall and / or load-bearing column connections;

[0081] Step 3: Install a U-shaped key at the fixed position control point on the ground and / or top of the installation location, and fix the lightweight partition wall board in the slot of the U-shaped key.

[0082] The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com