High-blackness high-brightness black master batch and preparation method thereof

A bright black, masterbatch technology, applied in the field of color masterbatch and its preparation, to achieve the effect of high brightness dispersibility and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A high-black high-gloss black masterbatch, comprising the following components by weight:

[0024] Carbon black BP71750%,

[0025] Low-density polyethylene LDPE-1C7A14.2%,

[0026] Linear low density polyethylene LLDPE-2650 19.09%,

[0027] Polyethylene wax AC-6A11.54%,

[0028] Lubricant wax H-50S4.67%,

[0029] Antioxidant AO-500.5%.

[0030] A preparation method of high-black and high-brightness black masterbatch, comprising the following technological process:

[0031] Stirring - banburying - granulation - dehydration - encapsulation.

[0032] The stirring refers to sequentially mixing linear low density polyethylene LLDPE-2650, polyethylene wax AC-6A, slip wax H-50S and antioxidant AO-50 at 19.09%, 11.54%, 4.67% and 0.5% Put the ratio into a high-speed mixer for stirring, the stirring time is 10 minutes, the stirring temperature is 60°C, and then wait for 1 hour to obtain the mixture a.

[0033] The banburying refers to the low density polyethylene LDPE-1C7A...

Embodiment 2

[0037] Plastic Modification Test

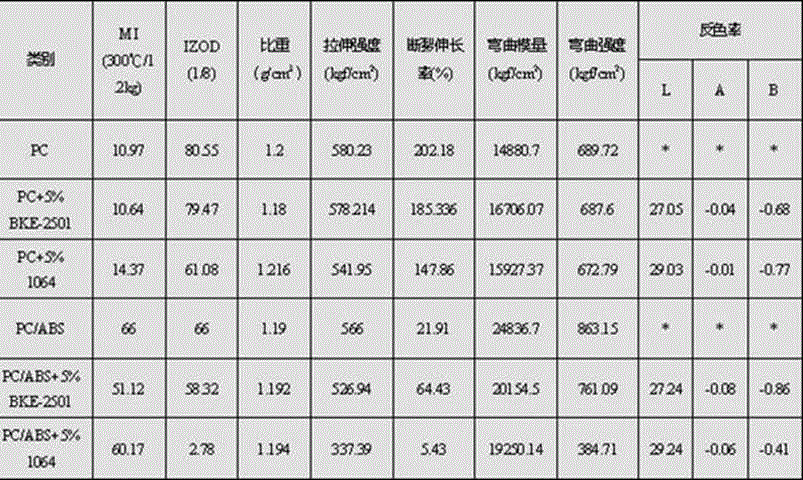

[0038] Taking the resin PC and PC / ABS as examples respectively, the effects of the black masterbatch BKE-2501 obtained in Example 1 and the existing black masterbatch 1064 on the market on the physical properties of the modified plastic are studied. The test results are shown in the table below :

[0039]

[0040] Analysis of test results: It can be seen from the above table that adding 5% of BKE-2501 has less effect on the physical properties of resin PC and PC / ABS than adding 5% of 1064; The value of the yellow-blue axis B is small, and the blue phase is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com