Preparation method of high temperature-resistant type precoated sand

A technology of high-temperature-resistant and coated sand, which is applied to casting molding equipment, casting molds, and cores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

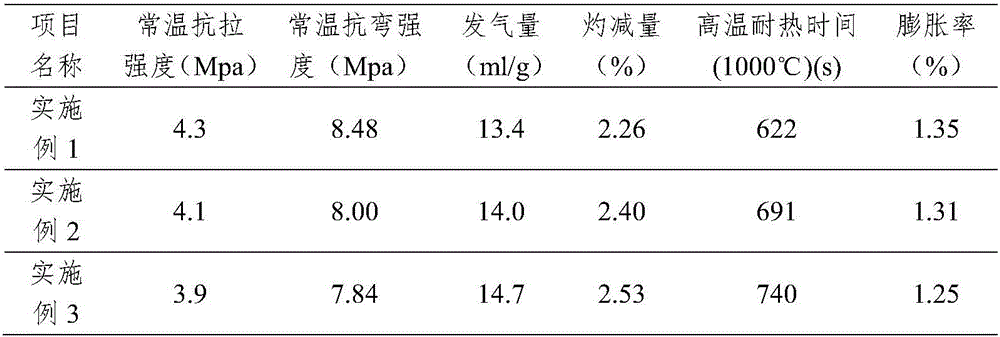

Examples

Embodiment 1

[0022] The preparation method of the high temperature resistant type coated sand in the present embodiment comprises the following steps:

[0023] Step 1: Heat the original sand, add the original sand to the sand mixer when the sand temperature rises to 140-160°C, then add the binder and mix the sand for 20s-120s to obtain the binder sand, and wait for the binder to be completely melted Then add high temperature resistant additives and lubricants in turn, and continue stirring to make the additives and lubricants evenly dispersed in the binder;

[0024] Step 2: When the sand temperature drops to 90-110°C, add the curing agent and mix for 20-50s to obtain the curing agent sand;

[0025] Step 3: Add lubricant to the curing agent sand again and mix the sand for 20-120s. When the sand temperature drops to 70-80°C, add the lubricant again and mix for 10-30s to produce sand to obtain high temperature resistant coated sand.

[0026] Wherein, the added weight of the binder is 1.5% of...

Embodiment 2

[0032] The steps of preparing high temperature resistant coated sand are the same as those in Example 1, and the difference from Example 1 lies in the ratio of each raw material component, and the difference is as follows:

[0033] The added weight of the binder is 2.0% of the total weight of the original sand, the added weight of the high temperature additive is 25% of the added weight of the binder, the added weight of the curing agent is 15% of the added weight of the binder, and the total added weight of the lubricant is. The weight is 6% of the added weight of the binder.

[0034] The high temperature resistant additives include: one or more selected from graphite, magnesium hydroxide, aluminum hydroxide, antimony trioxide, zinc borate and triphenyl phosphate.

[0035] The specific choice of which high temperature resistant additive in graphite, magnesium hydroxide, aluminum hydroxide, antimony trioxide, zinc borate, and triphenyl phosphate should be determined according ...

Embodiment 3

[0039] The steps of preparing high temperature resistant coated sand are the same as those in Example 1, and the difference from Example 1 lies in the ratio of each raw material component, and the difference is as follows:

[0040] The added weight of the binder is 2.5% of the total weight of the original sand, the added weight of the high temperature resistant additive is 30% of the added weight of the binder, and the added weight of the curing agent is 20% of the added weight of the binder, The added weight of the lubricant is 6% of the added weight of the binder;

[0041] The high temperature resistant additives include: one or more selected from graphite, magnesium hydroxide, aluminum hydroxide, antimony trioxide, zinc borate and triphenyl phosphate.

[0042] The specific choice of which high temperature resistant additive in graphite, magnesium hydroxide, aluminum hydroxide, antimony trioxide, zinc borate, and triphenyl phosphate should be determined according to the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com