Preparation method of thin-wall A-type graphite casting piece A

A technology of graphite and castings, which is applied in the field of preparation of thin-walled A-type graphite castings, and can solve the problems that the oil passages in the inner cavity are prone to have pores and scars, which cannot meet the requirements of tensile strength, hardness and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] On April 7, 2012, eight 50237500-type castings were produced according to the above method. The composition of the castings was tested: carbon 3.35%, silicon 1.9%, manganese 0.89%, sulfur 0.08%, chromium 0.226%, copper 0.516%, A-type graphite> 90 %.

[0054] The body hardness is 194HBW, the tensile strength is 260 MPa, and the air tightness test pressure is greater than 20bar.

Embodiment 2

[0056] On April 17, 2012, eight 50234700-type castings were produced according to the above method. The composition of the castings was tested: carbon 3.34%, silicon 1.82%, manganese 0.908%, chromium 0.259%, copper 0.551%, and A-type graphite> 90%.

[0057] The body hardness is 205HBW, the tensile strength is 263 MPa, and the air tightness test pressure is greater than 20bar.

Embodiment 3

[0059] On May 4, 2012, eight 50237100-type castings were produced according to the above method. The composition of the castings was tested: carbon 3.36%, silicon 1.8%, manganese 1.09%, chromium 0.254%, copper 0.6%, and A-type graphite> 90%.

[0060] The body hardness is 198HBW, the tensile strength is 259 MPa, and the air tightness test pressure is greater than 20bar.

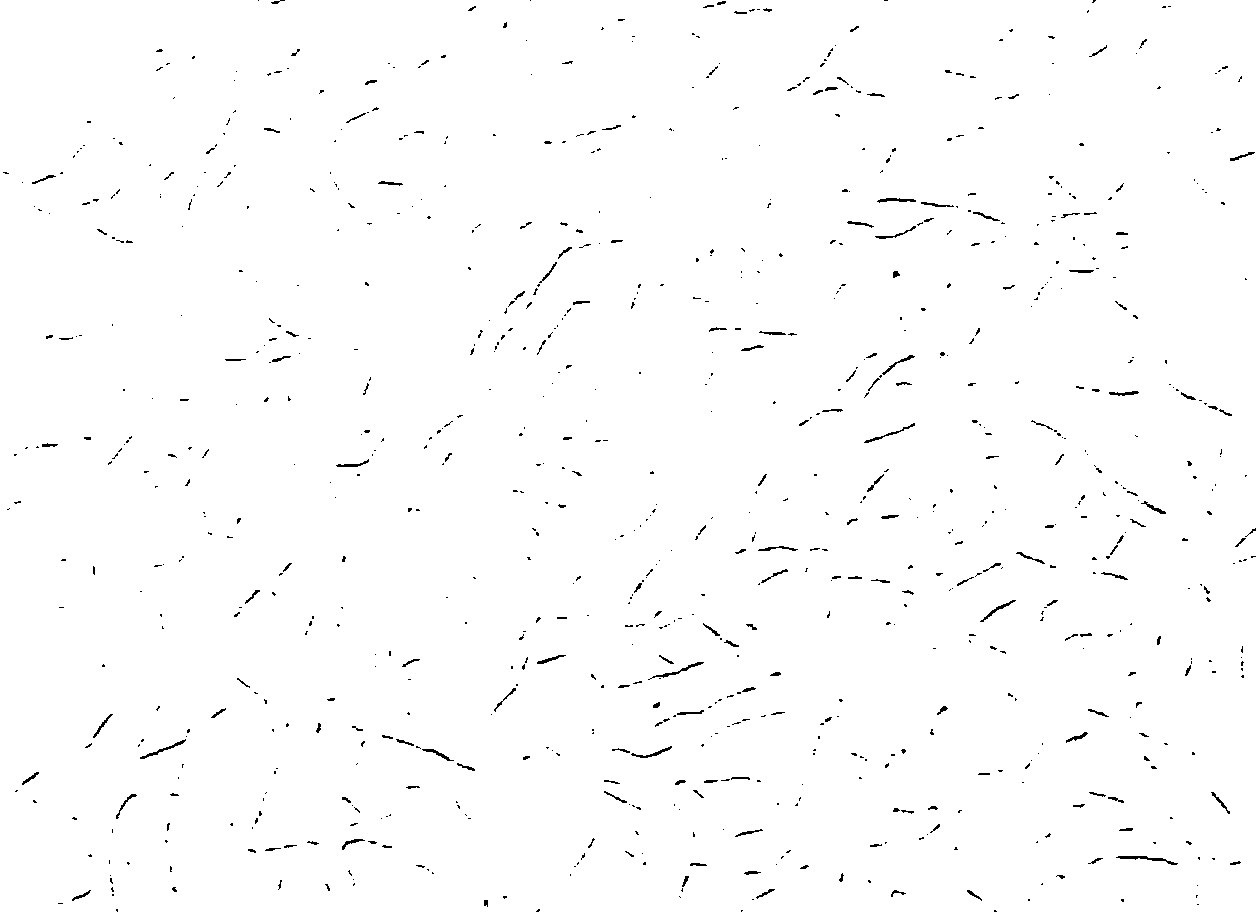

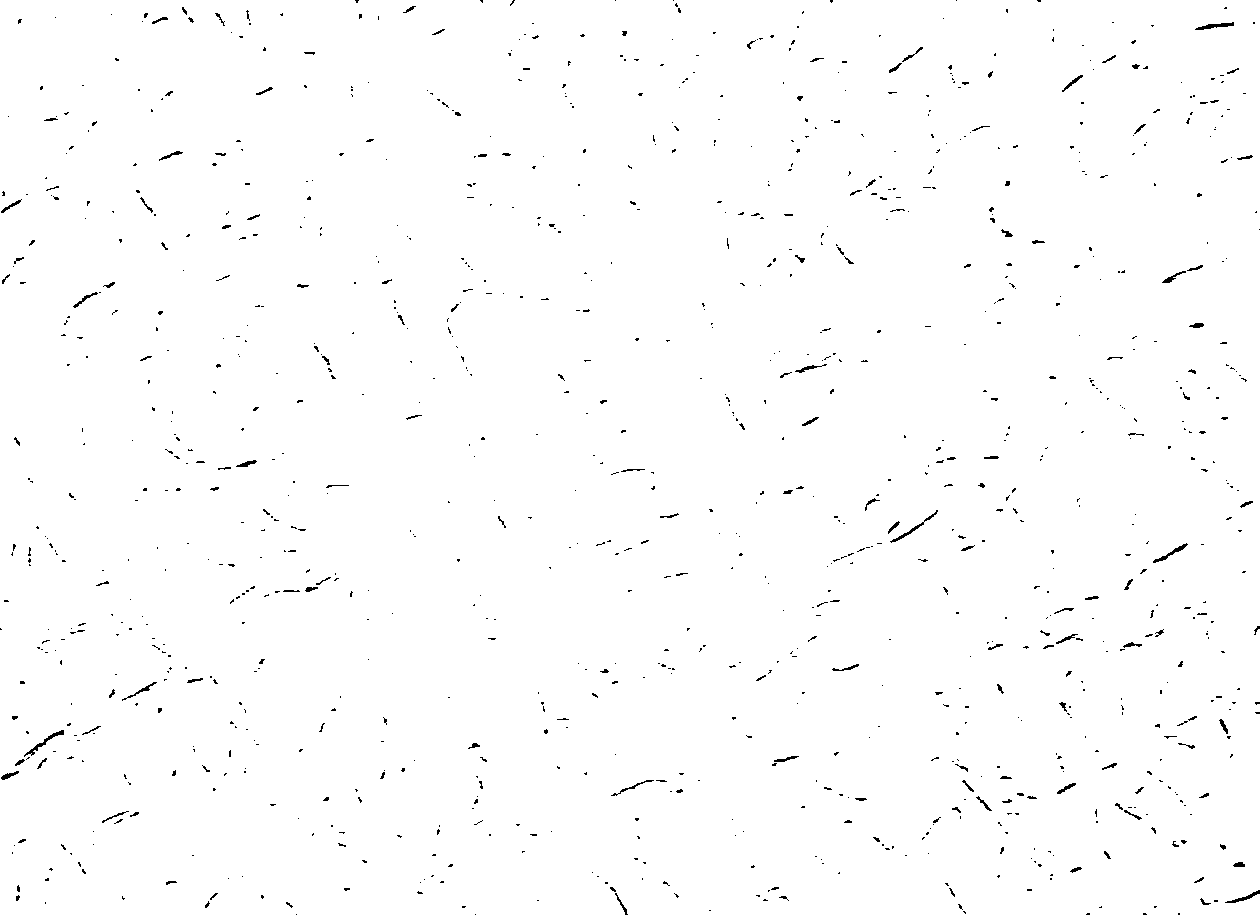

[0061] Moreover, it can be seen from the drawings of the description that the metallographic structure of the A-type graphite casting produced by the method of the present invention is more uniform, the graphite distribution is more uniform and non-directional, and it reaches the A-type graphite standard stipulated by the state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com