Semi-continuous anti-blocking subcritical/supercritical reaction heating device

A heating device and anti-clogging technology, applied in chemical/physical processes, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve problems such as high carbon production rate, inappropriateness, and blockage, and achieve safe operation, The effect of solving thickness and strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

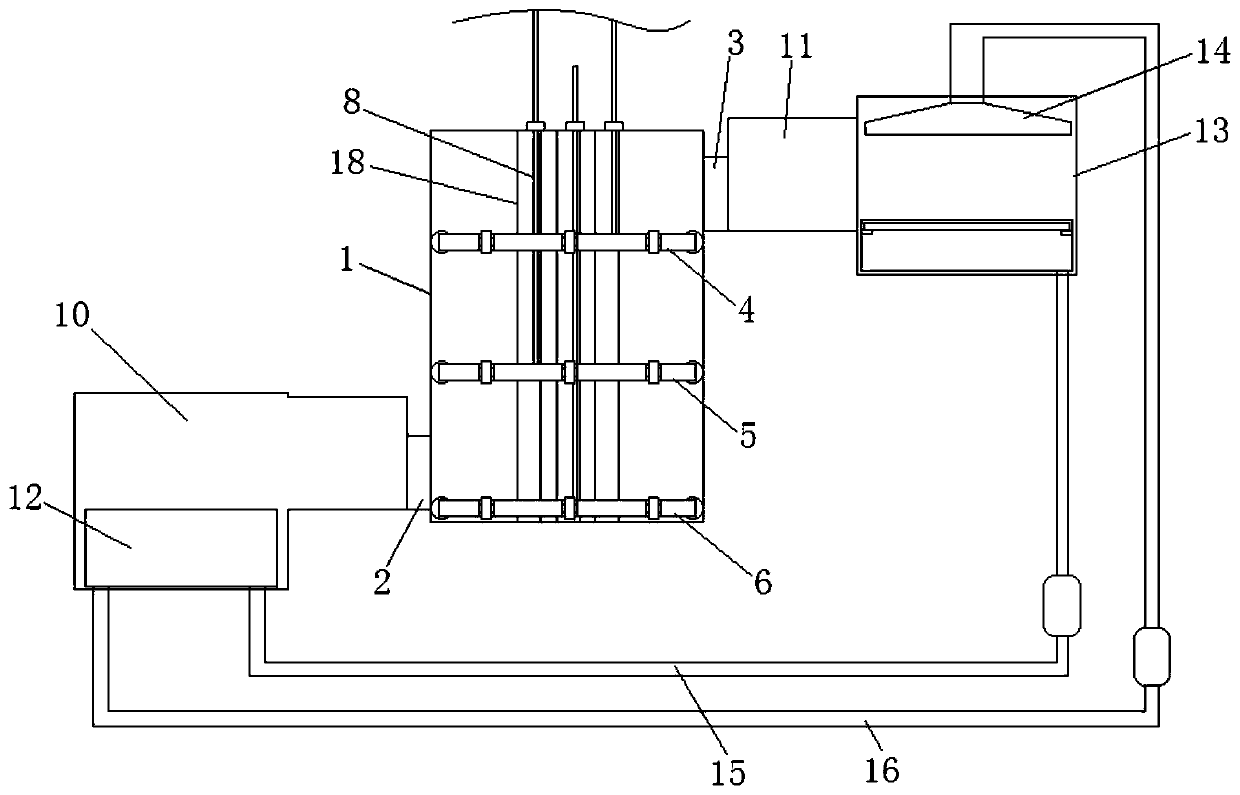

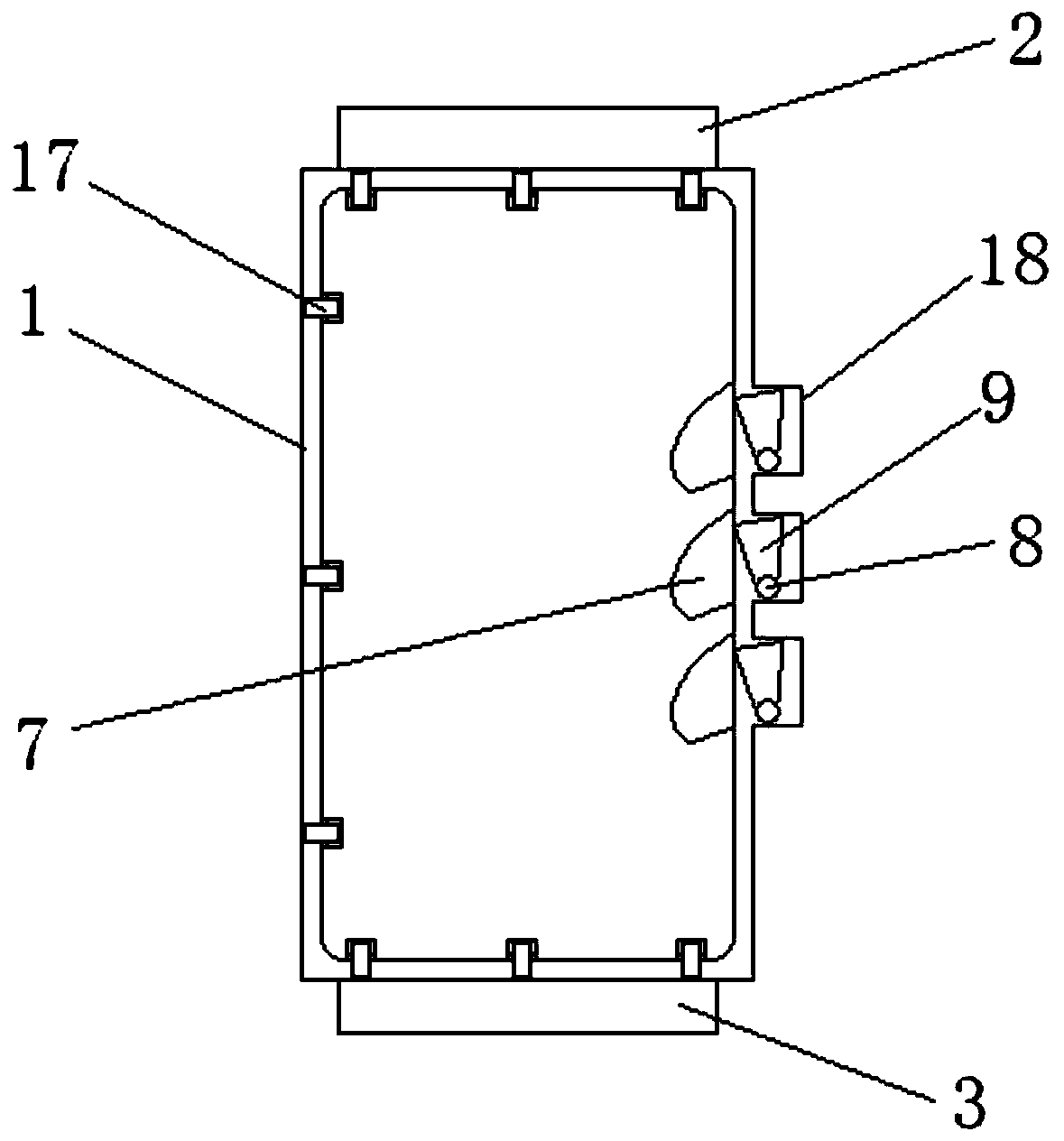

[0020] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] A semi-continuous anti-clogging sub / supercritical reaction heating device of the present invention comprises a hollow furnace body 1, the inner hollow structure of the furnace body 1 is a cuboid, and the lower side and the upper side of the furnace body 1 are respectively provided with feeding ports 2 and the discharge port 3, the feed port 2 and the discharge port 3 are located in the two directions of the furnace body 1, and are respectively located on the short side of the cuboid structure of the furnace body 1; the furnace body 1 is sequentially provided with first Supporting plate 4, the second supporting plate 5, the third supporting plate 6, described first supporting plate 4, the second supporting plate 5, the third supporting plate 6 are rectangular structures, the first supporting plate 4, the second supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com