Electrode cylinder support structure for large-diameter capacitive liquid hydrogen density sensor

A technology of density sensor and support structure, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of the influence of density measurement value, can not meet the requirements of purging and replacement, and the strength can not meet the requirements, and achieve reliable performance, guarantee stability, The effect of meeting insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

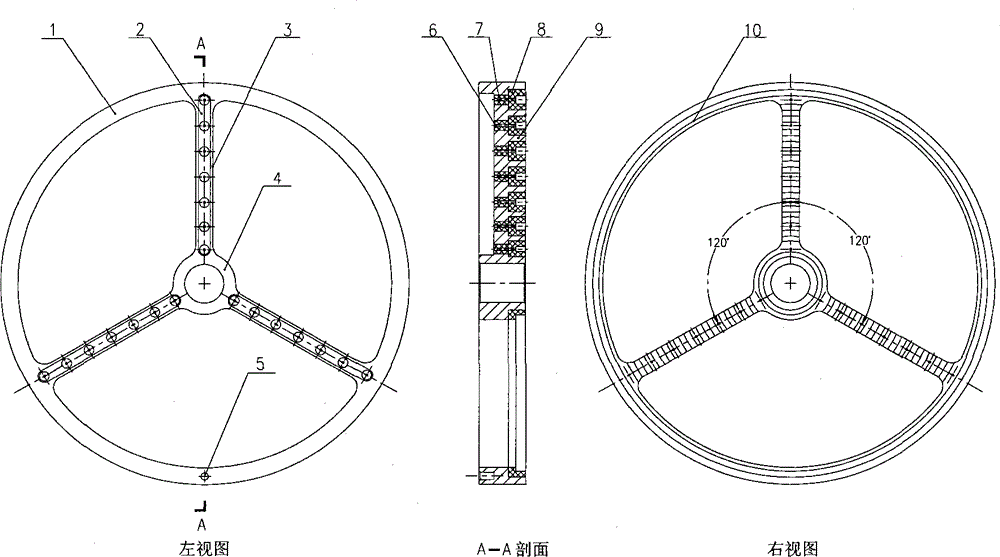

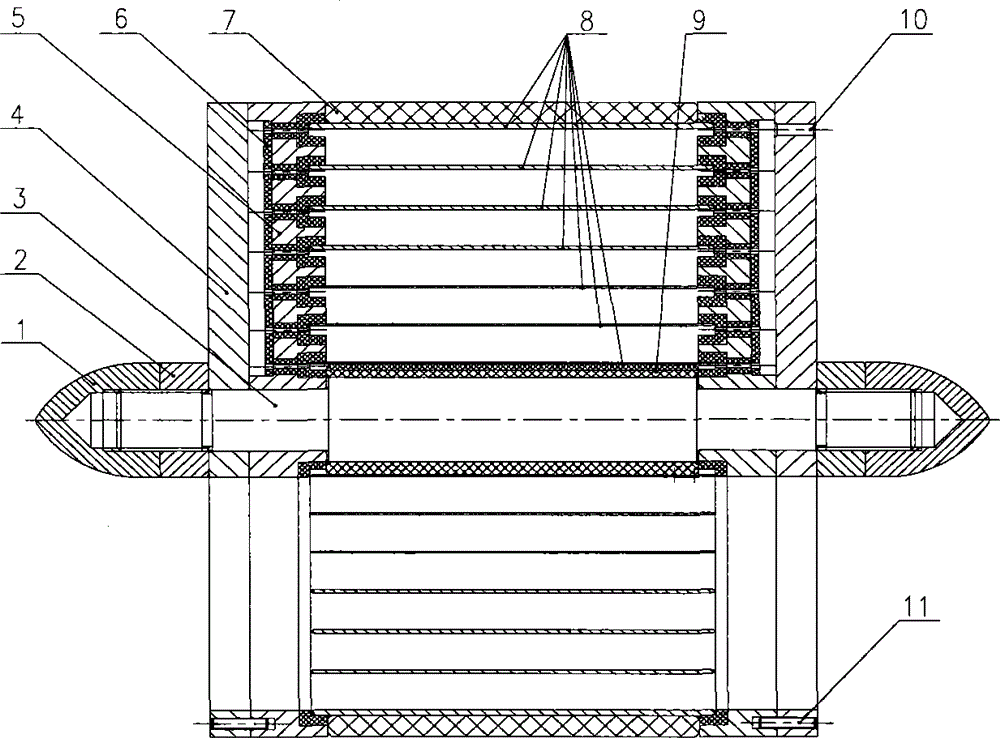

[0013] Specific implementation case 1: the following combination of technical solutions and attached figure 1 , and refer to the attached figure 2 , to describe the implementation examples of the present invention in detail.

[0014] The large ring 1, support rib 3, and small ring 4 of the support structure of the present invention are mechanically processed in one body, the outer diameter of the large ring 1 is consistent with the inner diameter of the liquid hydrogen delivery pipeline, and the inner diameter of the small ring 4 is the same as the mandrel (attached figure 2 The outer diameter of "3") is the same. The outer surfaces of the three support ribs 3 are each processed with a wire slot 2 in the radial direction, and the lead wires of each electrode cylinder of the same pole pass through the threading through hole 6 and a polytetrafluoroethylene insulating strip (attached figure 2 middle "6"), after being welded together, place them in the wire slot 2; the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com