Casting method of sand core oil tube of internal combustion engine

A technology for internal combustion engines and oil pipes, which is applied in the casting field of internal combustion engine sand core oil pipes, can solve problems such as not being overcome, and achieve the effects of solving fixed problems, precise oil pipe dimensions, and increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

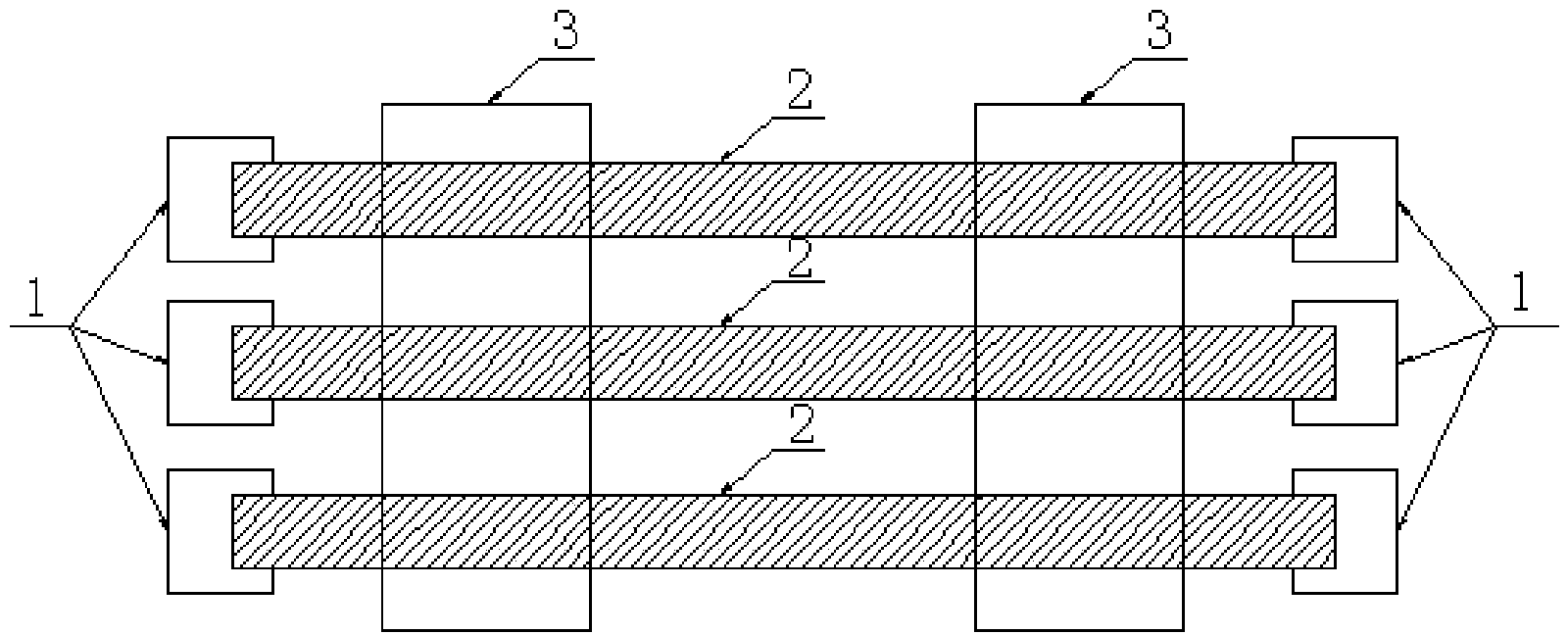

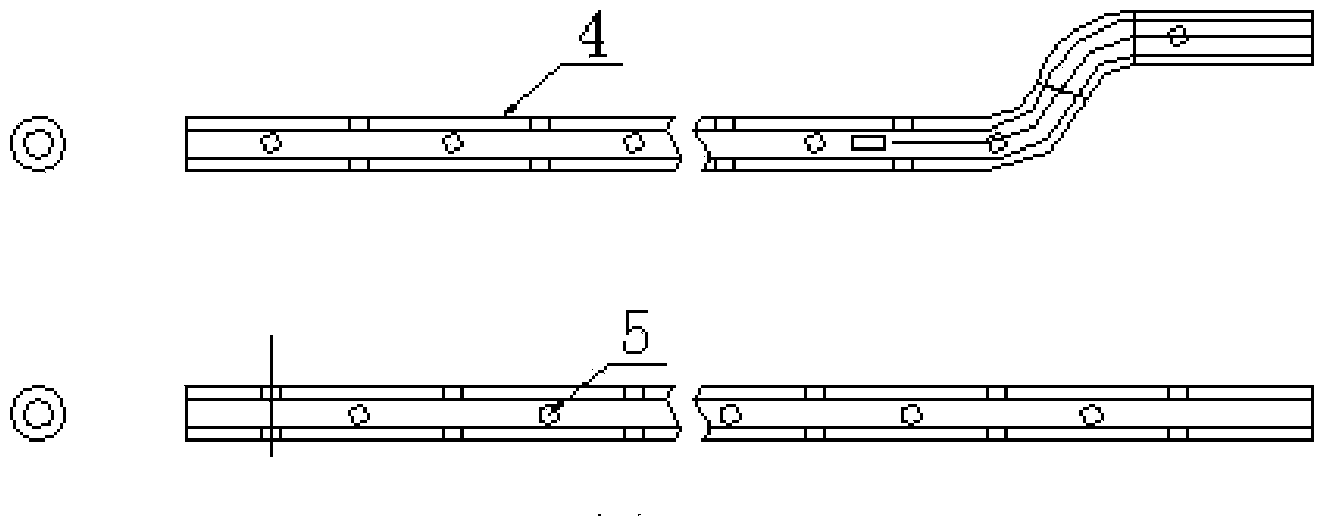

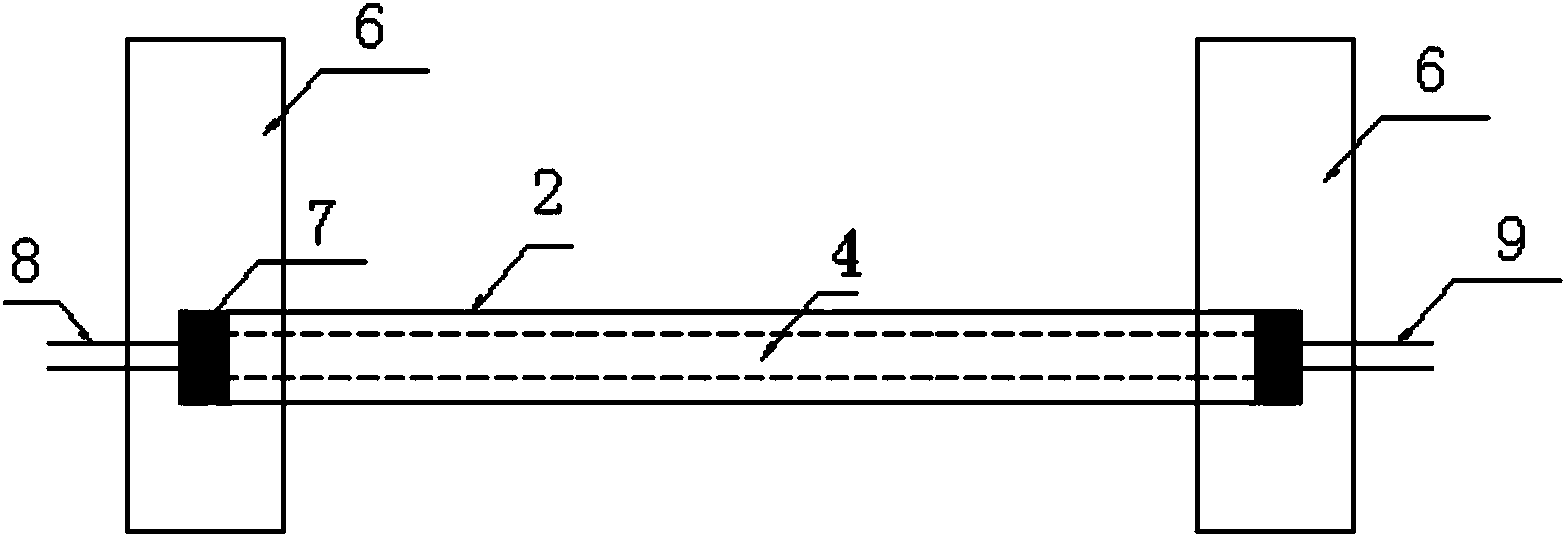

[0026] A casting method for oil pipes with sand cores of internal combustion engines, including molding, core making, box closing and pouring, characterized in that: oil pipe sand cores are used for positioning when making cores, that is, oil pipe cores pass through all inner cavity cores, and the outer mold cores on both sides The position of the oil pipe is determined by the positioning of the head, the steel pipe is selected as the core iron, and the raw material of the oil pipe core is chromite sand; when the oil pipe sand core is bent and deformed when the box is closed, the end is added to the end of the lost foam shrinkage joint, and the compressed air is blown for forced cooling. Add a special anti-leakage core support to the oil pipe part of the tank.

[0027] The surface of the core iron steel pipe is crossed with holes of ф5mm, and the steel pipe is fully shot blasted before use.

[0028] The ingate is far away from the oil pipe sand core.

[0029] The blowing of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com