Patents

Literature

72results about How to "Rich in change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

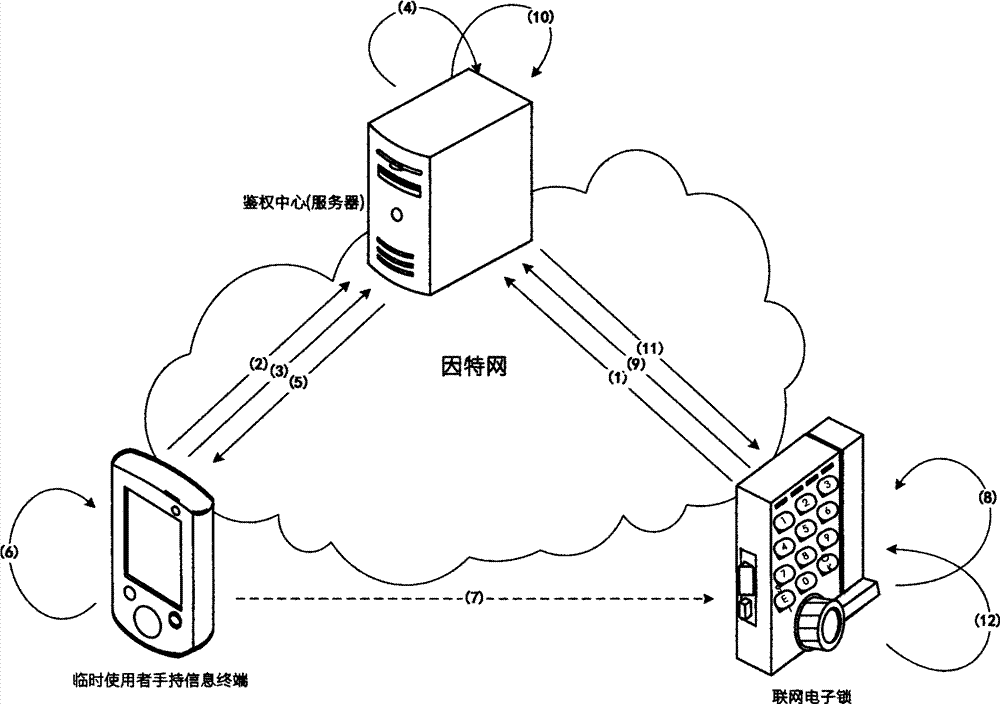

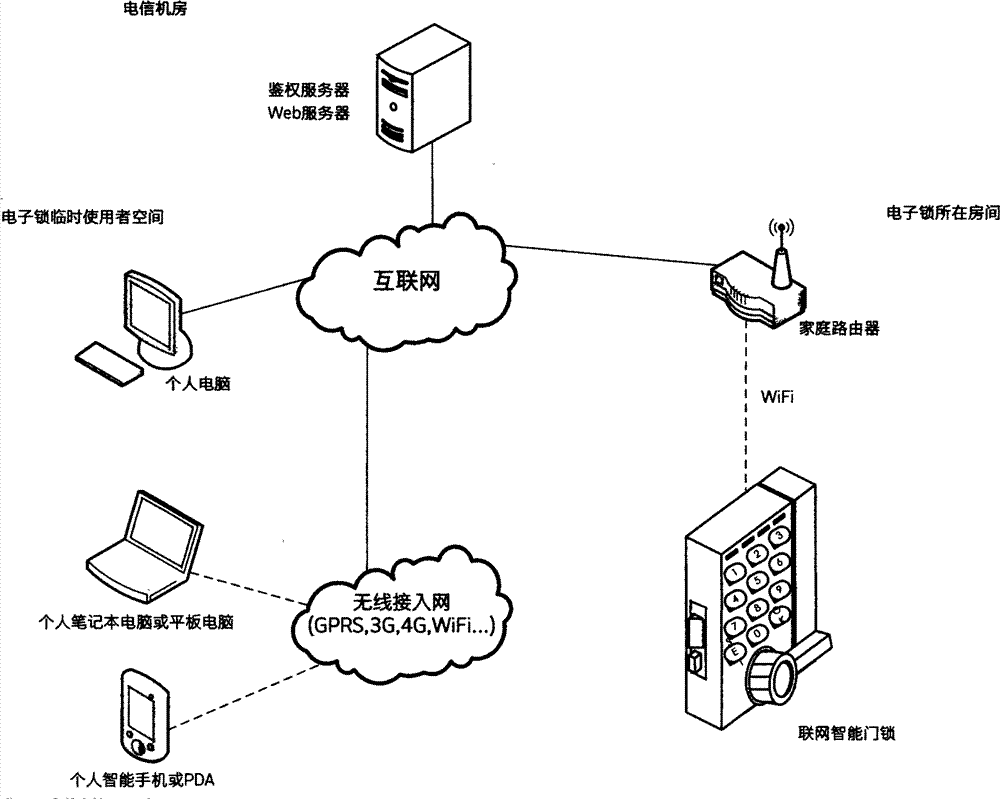

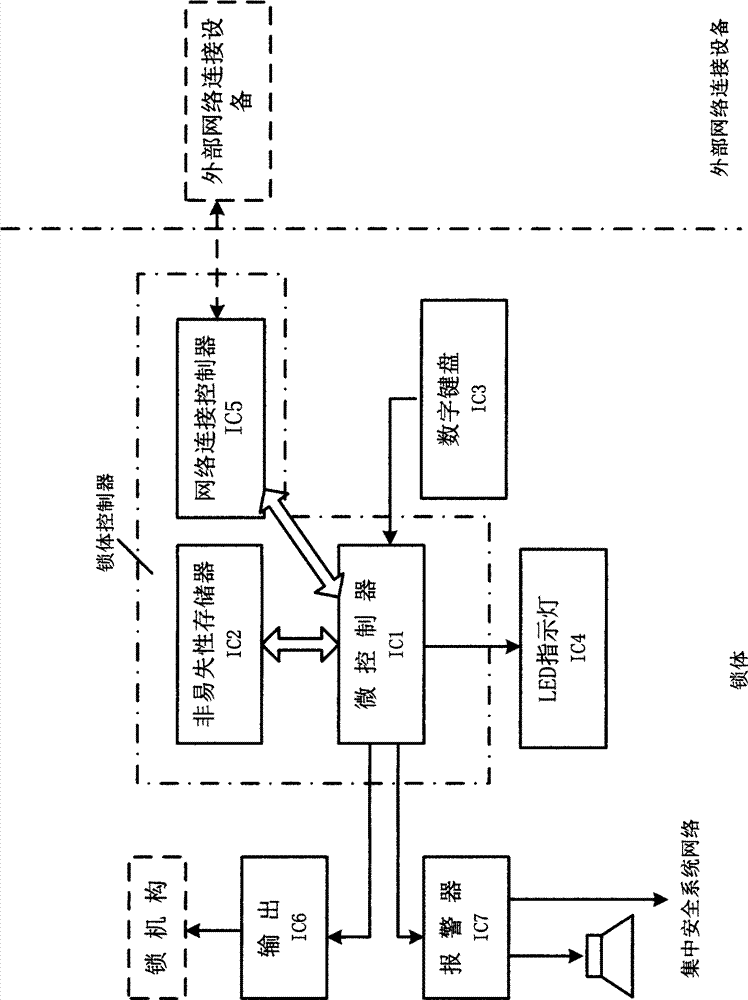

Electronic lock system based on internet dynamic authorization

InactiveCN103903319ARich in changeEasy to apply for and use authorizationIndividual entry/exit registersSpecific timeAuthorization

The invention provides an internet-based electronic lock system capable of being flexibly authorized. According to the electronic lock system, an electronic lock and an information terminal of a temporary user can be connected with an authentication center A by the internet; an owner and the temporary user of the electronic lock can register or log out at the authentication center at any time at will; when a specific electronic lock L and the temporary user of the electronic lock register at the authentication center (such as a computer server on the internet), the authentication center A stores authorization information and gives a specific authorization code P to the temporary user after the temporary user hopes to use the electronic lock at specific time and is authenticated, so that the temporary user can open the electronic lock by using the authorization code at the specific time; the electronic lock is connected with the authentication center through the internet to carry out the authentication and the lock is opened after the authentication is passed.

Owner:袁磊

Ceramic brick distribution equipment and process

The invention discloses ceramic brick distribution equipment and a ceramic brick distribution process. The equipment comprises a frame, and a blank conveying mechanism and a texture distribution mechanism arranged on the frame, wherein the texture distribution mechanism is positioned above the blank conveying mechanism. The equipment is characterized in that: the texture distribution mechanism mainly consists of a plurality of groups of unloading devices arranged side by side for loading a pattern material and a line material, a feeding belt arranged below the unloading devices, and a belt type collecting box capable of randomly arranging and centralizing the line material and the pattern material into distribution textures, wherein the belt type collecting box is arranged between the feeding belt and the blank conveying mechanism. The press molded floral colored patterns are natural, vivid and rich in change and are not repeated; and the production process is simple, and the production efficiency is high.

Owner:LIXIAN XINPENG CERAMIC +3

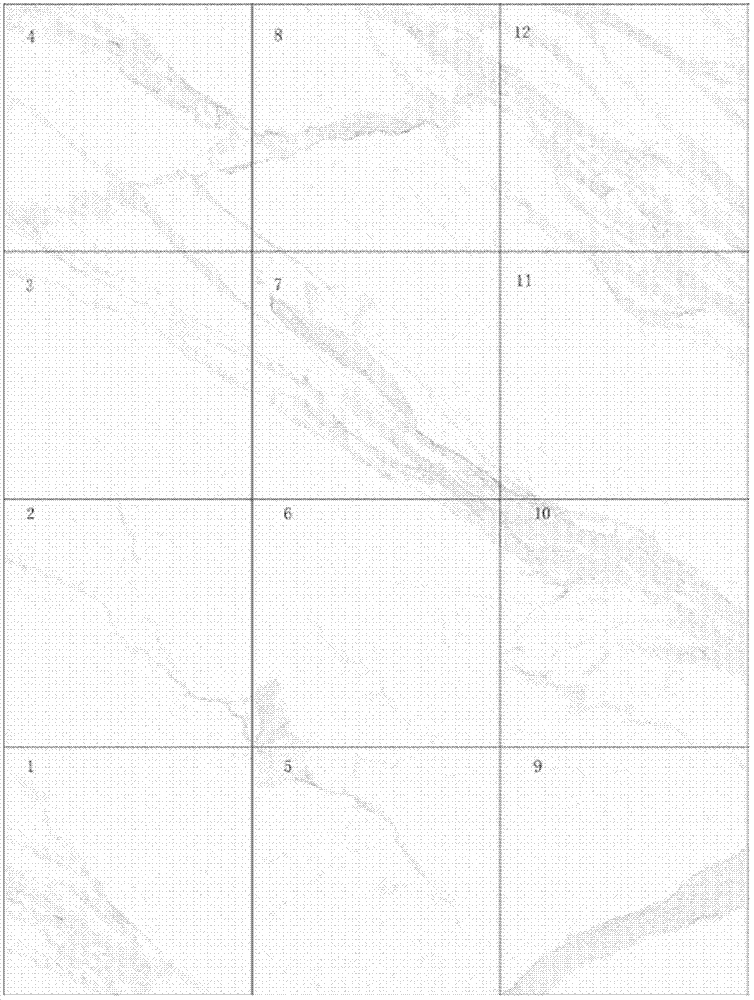

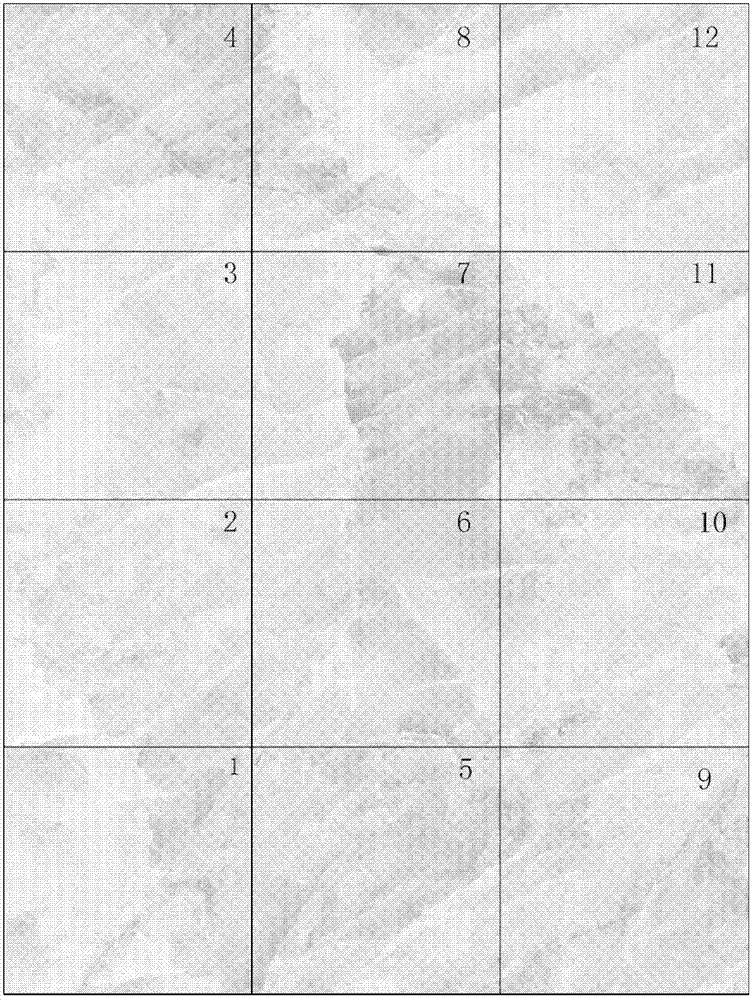

Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

InactiveCN103241049AStrong three-dimensional senseStrong sense of transparencyDecorative surface effectsClaywaresMetallurgyNatural stone

The invention relates to a manufacturing method for a combined ceramic tile with a complete pattern, which is spliced by a plurality of ceramic tiles. The method comprises the following steps of: mixing raw materials to prepare a powder material, pressing the powder material to obtain green tiles, carrying out printing and glaze spraying on the green tiles, sintering the obtained tiles to obtain the ceramic tiles, and performing seamless splicing on the plurality of ceramic tiles with different or identical figures to obtain the combined ceramic tile with the complete pattern. Compared with the prior art, the combined ceramic tile can fully display the real effect of natural stones by means of large format splicing, is strong in three-dimensional effect and rich in layering, can better adapt to current market trend, and is grand and very impressive after being paved.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

Production method for ceramic brick with natural concave-convex surface

The invention relates to a production method for ceramic tile with natural rough surface. It is characterized by the following steps: spraying right amount of water onto the dry green body surface, roasting the green brick surface under high temperature to quickly vaporize the water on the surface so as to crack the green brick surface irregularly, then removing the cracked clay on the surface to form natural rough surface, finally roasting the green brick in the ceramic tile roller kiln. The ceramic tile produced by the invented method has natural, stereo, variable patterns on surface.

Owner:FOSHAN OCEANO CERAMICS

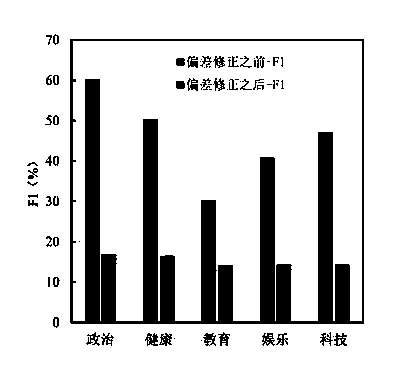

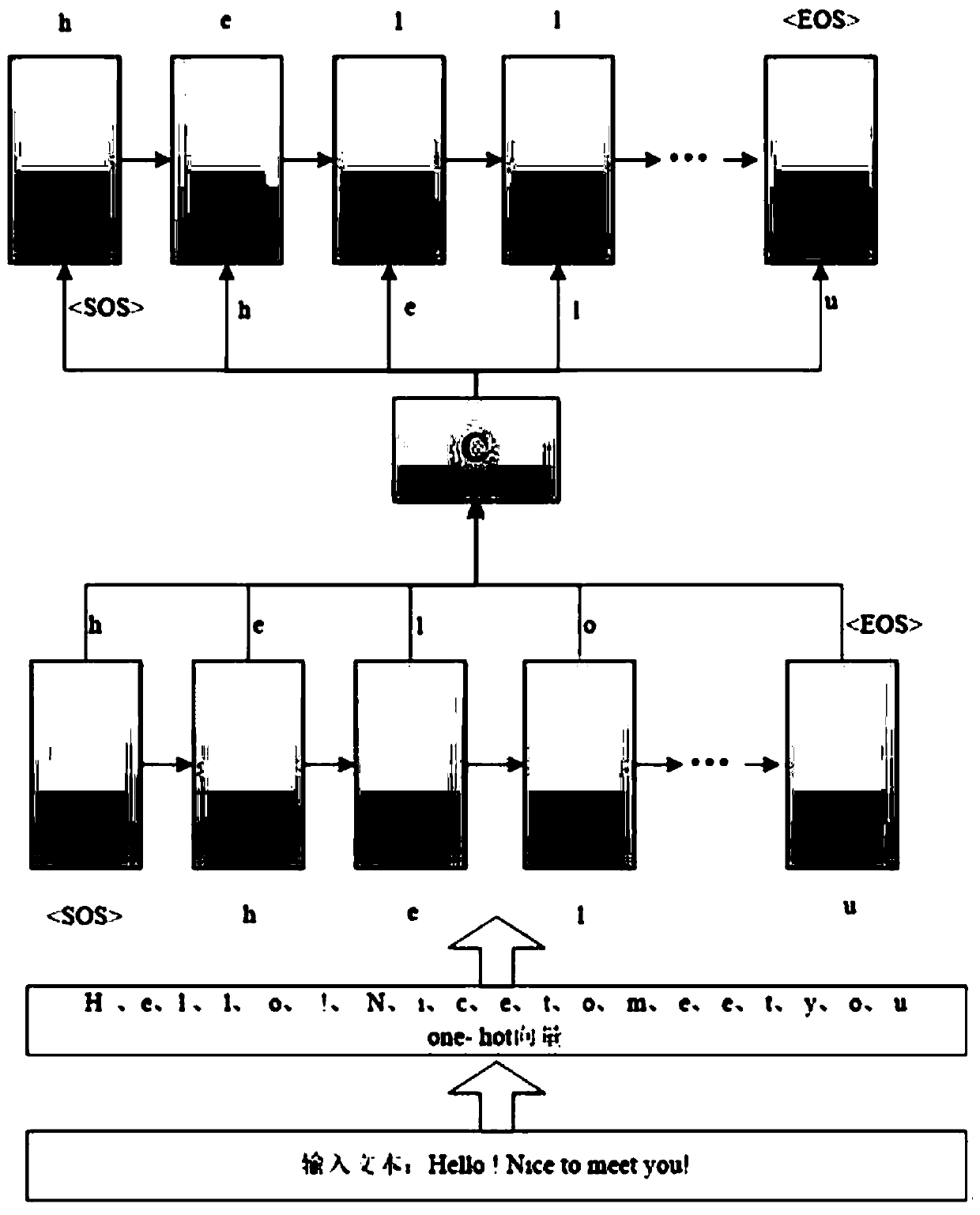

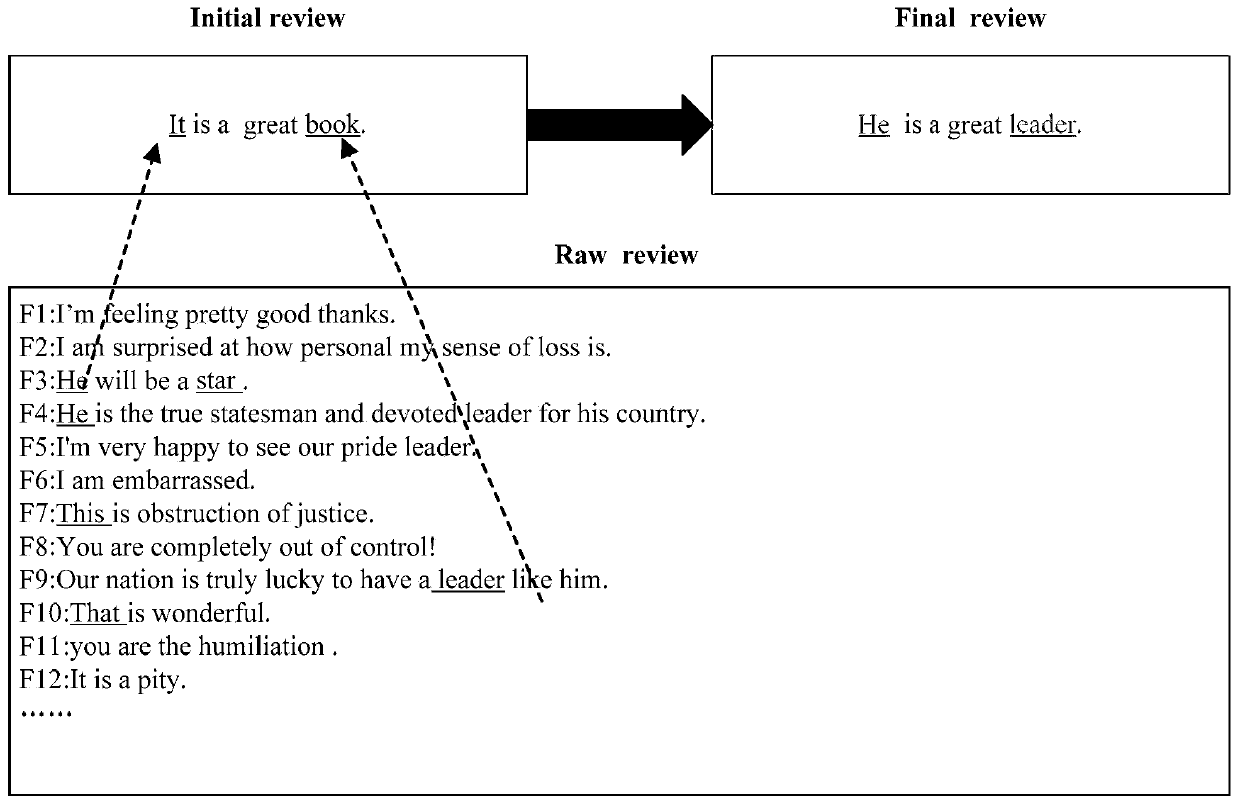

Social network comment generation method based on LSTM

PendingCN110390018ARich in changeSafeguard the atmosphere of public opinionData processing applicationsWeb data indexingSemanticsPositive energy

The invention discloses a social network comment generation method based on LSTM, and belongs to the technical field of social network comment generation. The social network comment generation methodand device solve the problem that a material library cannot be provided for public opinions due to the fact that an applied scene of an existing social network comment generation technology is too narrow and single. According to the method, an NLG technology based on LSTM learning is used, and the visual semantics of a sentence structure, the types of characters and each character are coded through the probability relation between the characters obtained through learning. Semantic and syntactic fusion is carried out on comment information to be expressed, and a vivid, smooth and variable high-quality comment text which is almost consistent with a social network is generated through methods such as specific word replacement in the later period. A favorable material corpus is provided for public opinion guidance, and a positive energy network environment is restored by spreading more real and trustworthy languages. The method can serve as a material corpus to be input into an existing public opinion guiding system, and is used for generating comments in the specific field of the social network.

Owner:HARBIN INST OF TECH

Indoor aromatic diatom ooze decorative wall material

InactiveCN103936337ANatural and beautiful textureImprove utilizationLiving environmentMaterials science

The invention provides an indoor aromatic diatom ooze decorative wall material, and relates to the field of building decorative materials. The wall material comprises kieselguhr, aromatic plant debris, a filler, aggregate, a photocatalyst material, a pigment and a gelling material, wherein the aromatic plant debris can be from different plants. By adding the aromatic plant debris to the wall material, the obtained diatom ooze decorative wall material can adsorb harmful gas and release pleasant aroma to create a comfortable living environment; by adding the aromatic plant debris, changeful texture patterns can be made on the wall material.

Owner:BEIJING DAIJIN DIATOMITE NEWLY BUILDING MATERIAL

Pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and production technology thereof

The invention discloses pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and a production technology thereof. The pure aloe fiber warp and weft double-elasticity yarn-dyed fabric comprises a warp yarn, a weft yarn and an elastic yarn, wherein 60S aloe fiber yarns are adopted as the warp yarn and the weft yarn; aloe 50S / 20D is adopted as the elastic yarn; a plain fancy cellular structure is adopted as a fabric structure; a bottom structure formed by plain as main material and triple fancy cellular structures in the transverse direction and longitudinal direction; an edge structure is the plain; and a jacquard part is formed by the fancy cellular structure as main part in transverse direction and horizontal direction matched with the shrinkage action of an aloe fiber spandex core-spun yarn. The production technology comprises a spooling step, a warping step, a slashing step, a drafting step and a weaving step. The fabric is reasonable in color match, light and thin in texture and slight in wrinkle, and gives a casual feeling to a consumer. Meanwhile, the pattern is relatively large in cycle, and is matched with unique plain fancy cellular structure, so that the fabric is high in third dimension and good in breathability. The weaving efficiency reaches 91%; and the first grade percentage put in storage reaches 99%.

Owner:IANGSU COLLEGE OF ENG & TECH

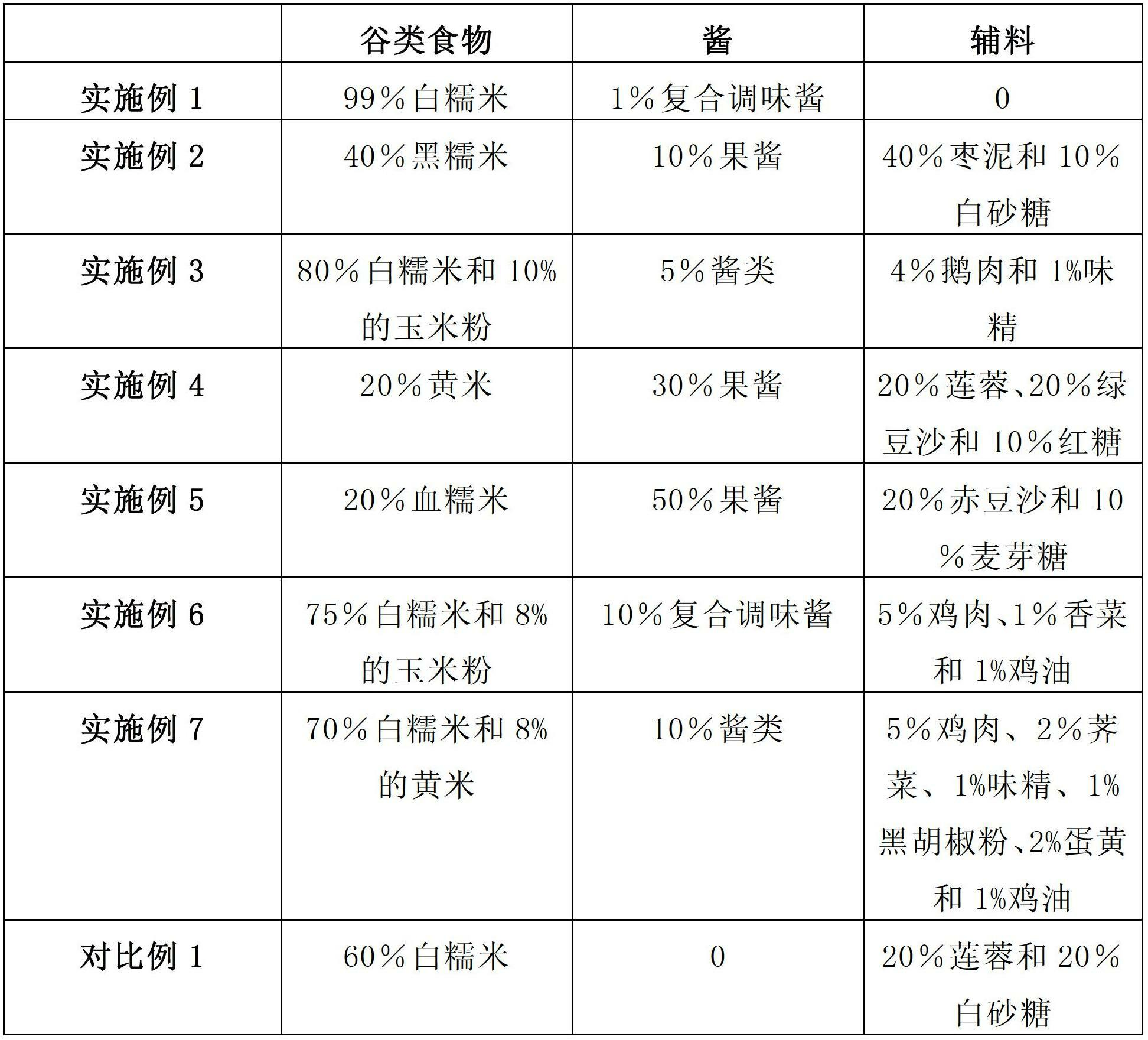

Rice dumpling with sauce

Owner:上海东锦食品集团有限公司

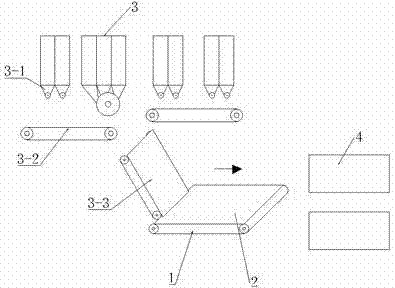

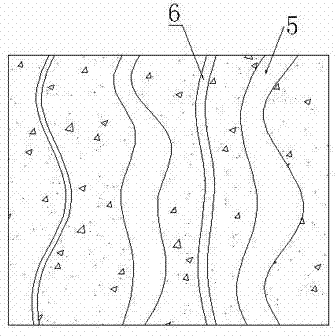

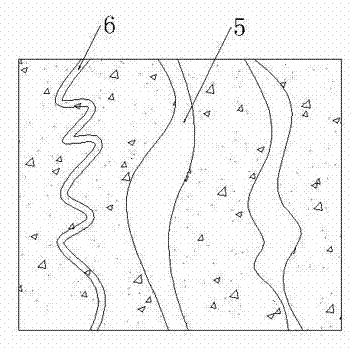

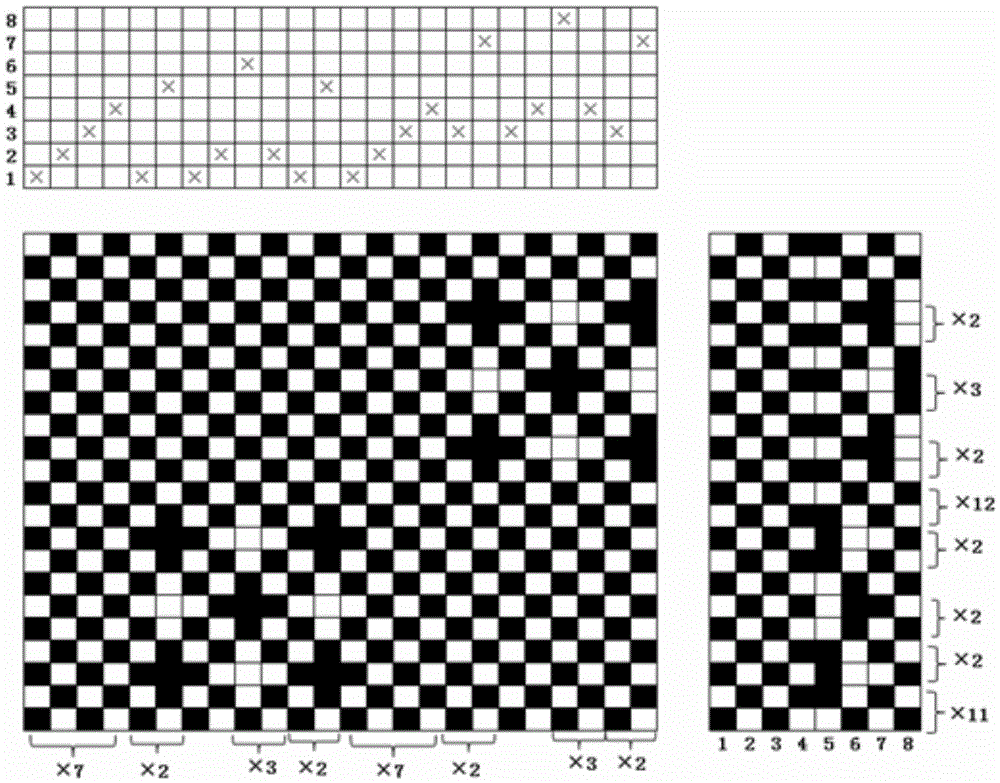

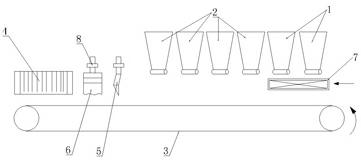

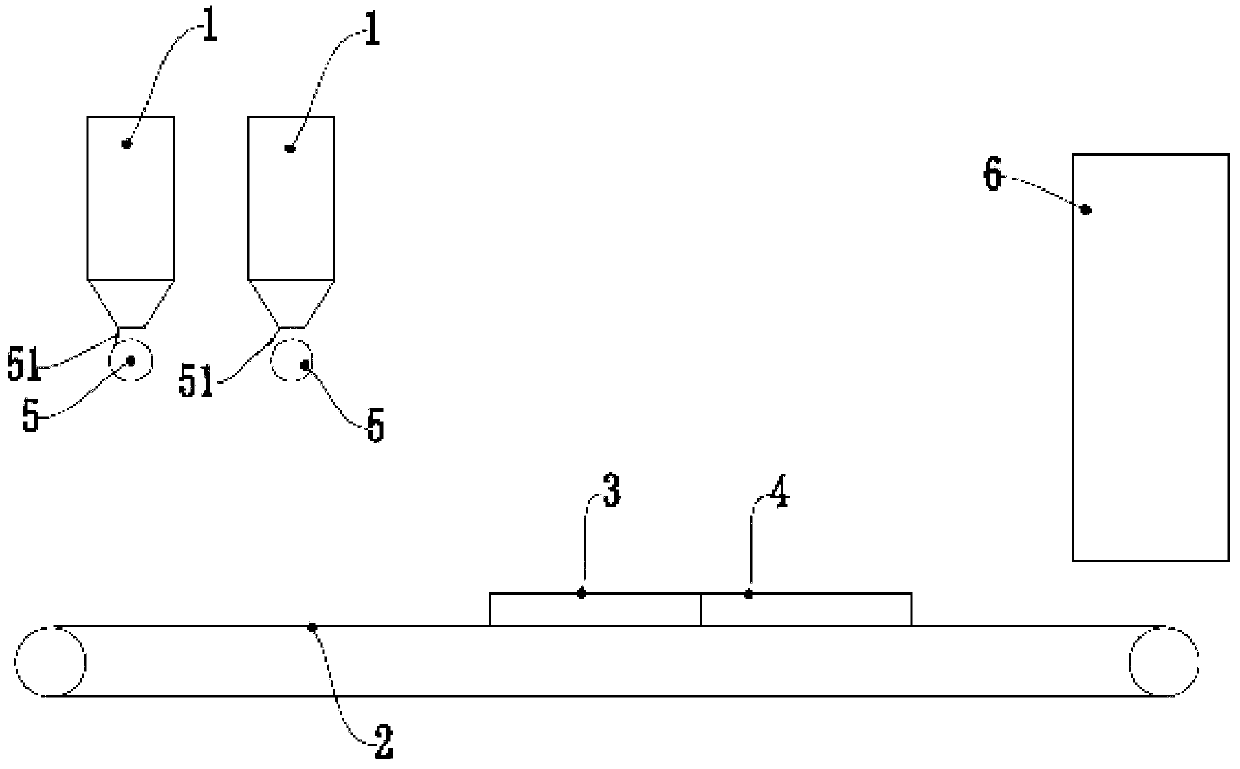

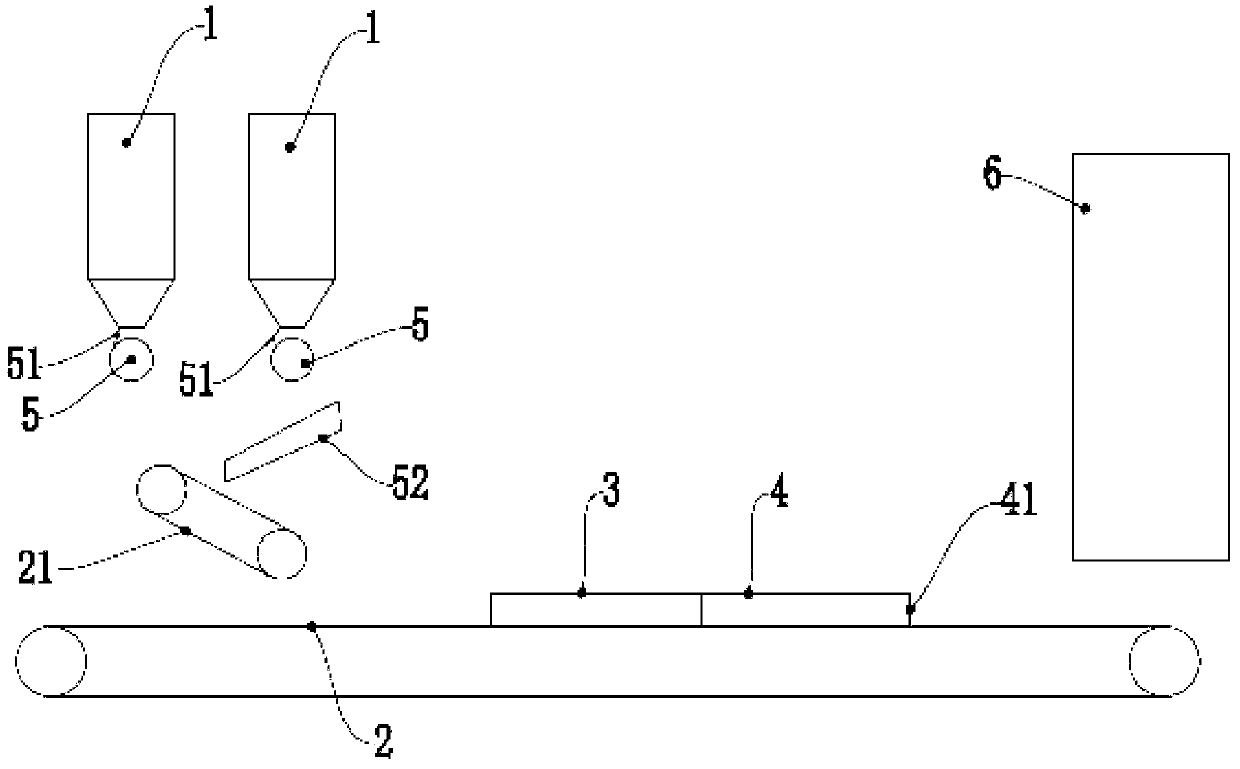

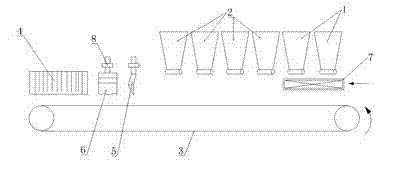

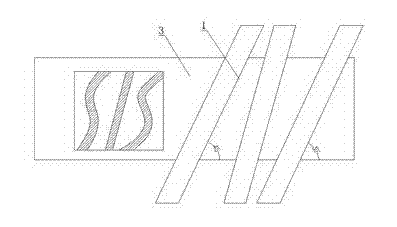

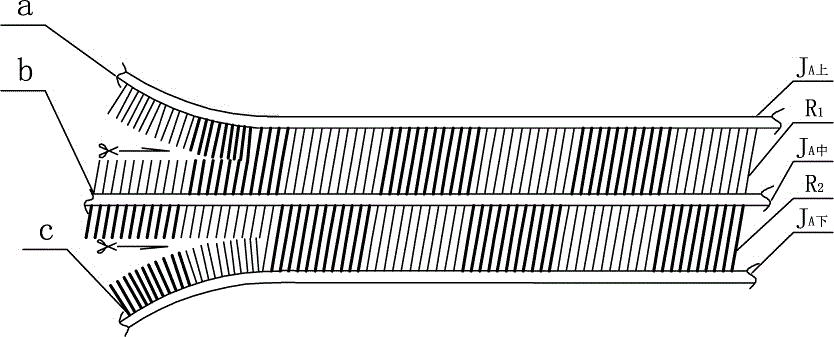

Material distributing method and equipment of polished tiles

ActiveCN102248595AEasy to replaceNatural texture decorative effectCeramic shaping apparatusBand shapeLamellar Pattern

The invention discloses a material distributing method and equipment of polished tiles. The method is characterized by comprising the following steps of: a. preparing materials: respectively distributing line materials and plus materials into a line material feeding hopper and a plus material feeding hopper which are arranged in the moving direction of a main conveyor belt; b. after the line materials are sieved by a vibration sieve, distributing the sieved line materials on the main conveyor belt to form a banded thin-layered line material, and distributing the plus materials on the main conveyor belt by virtue of the intermittent opening and closing of the plus material feeding hopper to form a banded thick-layered plus material; c. enabling the banded thick-layered plus material to be formed into linear lamellar patterns with lines by virtue of the intermittent blocking action of a linear baffle, and warping the linear material layer into a wavy material layer by virtue of the intermittent blocking action of a wavy baffle; and d. transferring the effect of the wavy material layer into a press mould by virtue of a texture fidelity feeding grate. In the invention, natural and delicate texture effects with rich layers in imitation of natural stones are formed by virtue of the combination of the formula and process provided by the invention; the equipment is easy to modify, so the equipment can be flexibly suitable for design modification requirements of products; and the product conversion cycle is shortened, and the loss and production cost are reduced.

Owner:FOSHAN DONGPENG CERAMIC +2

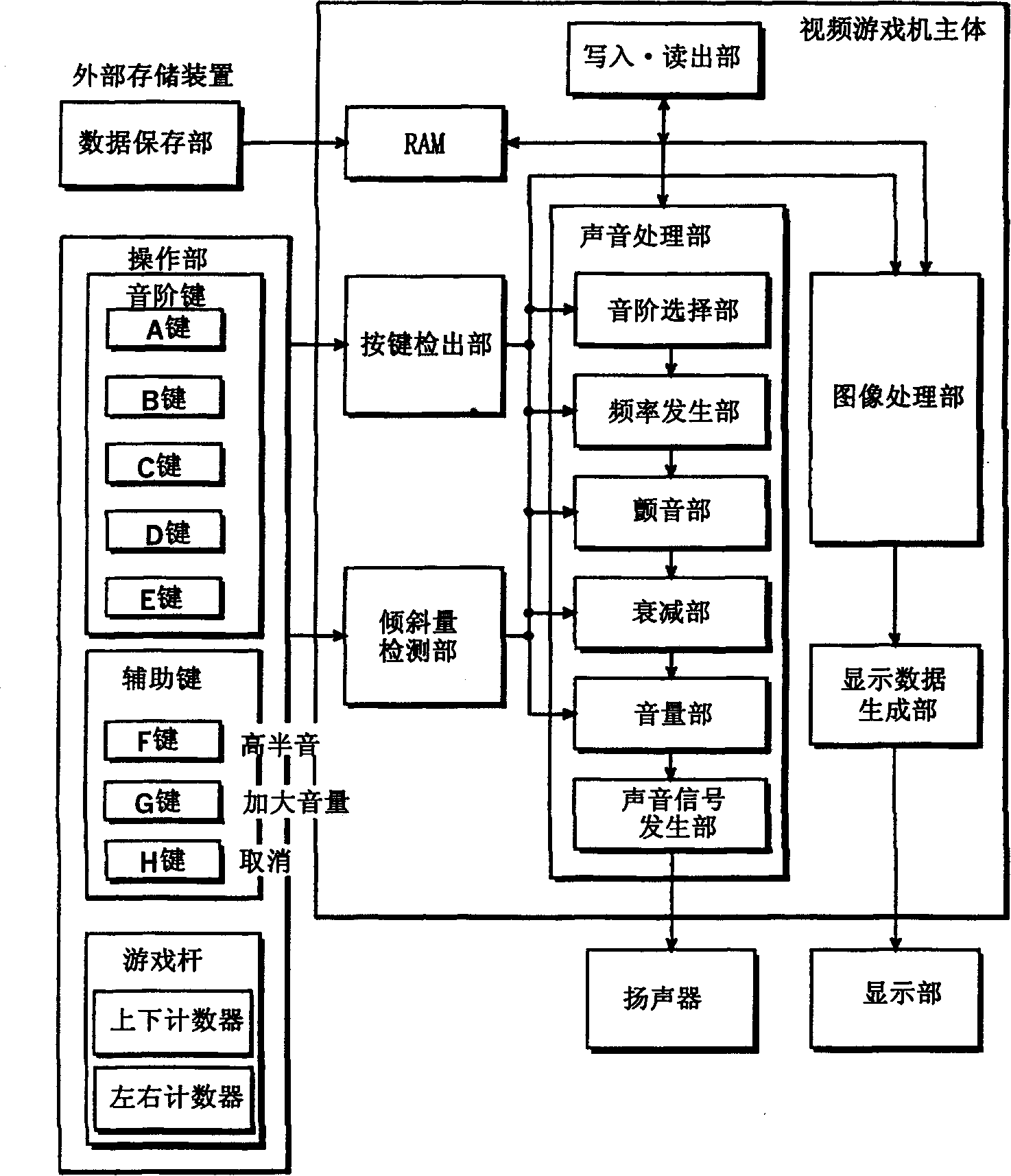

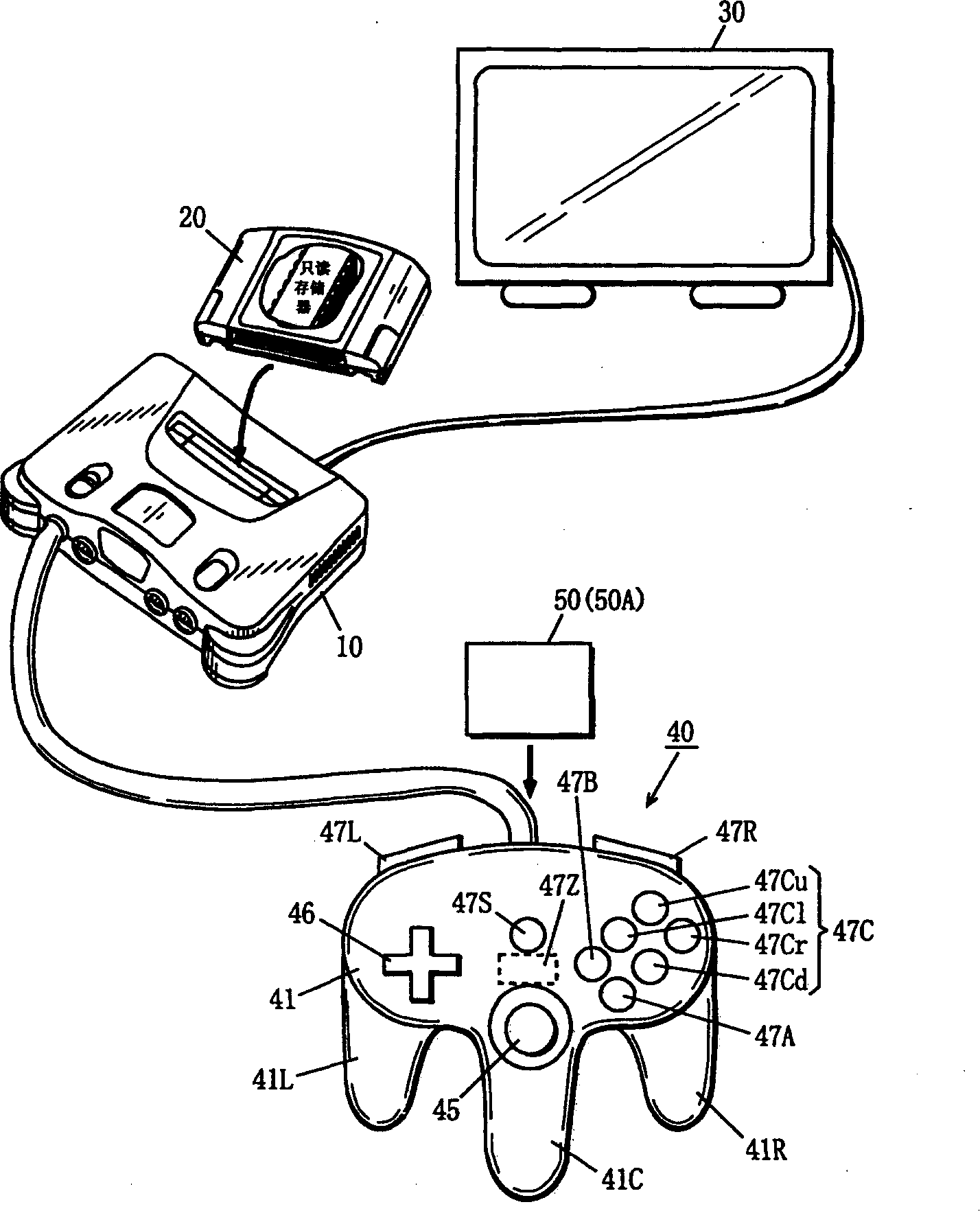

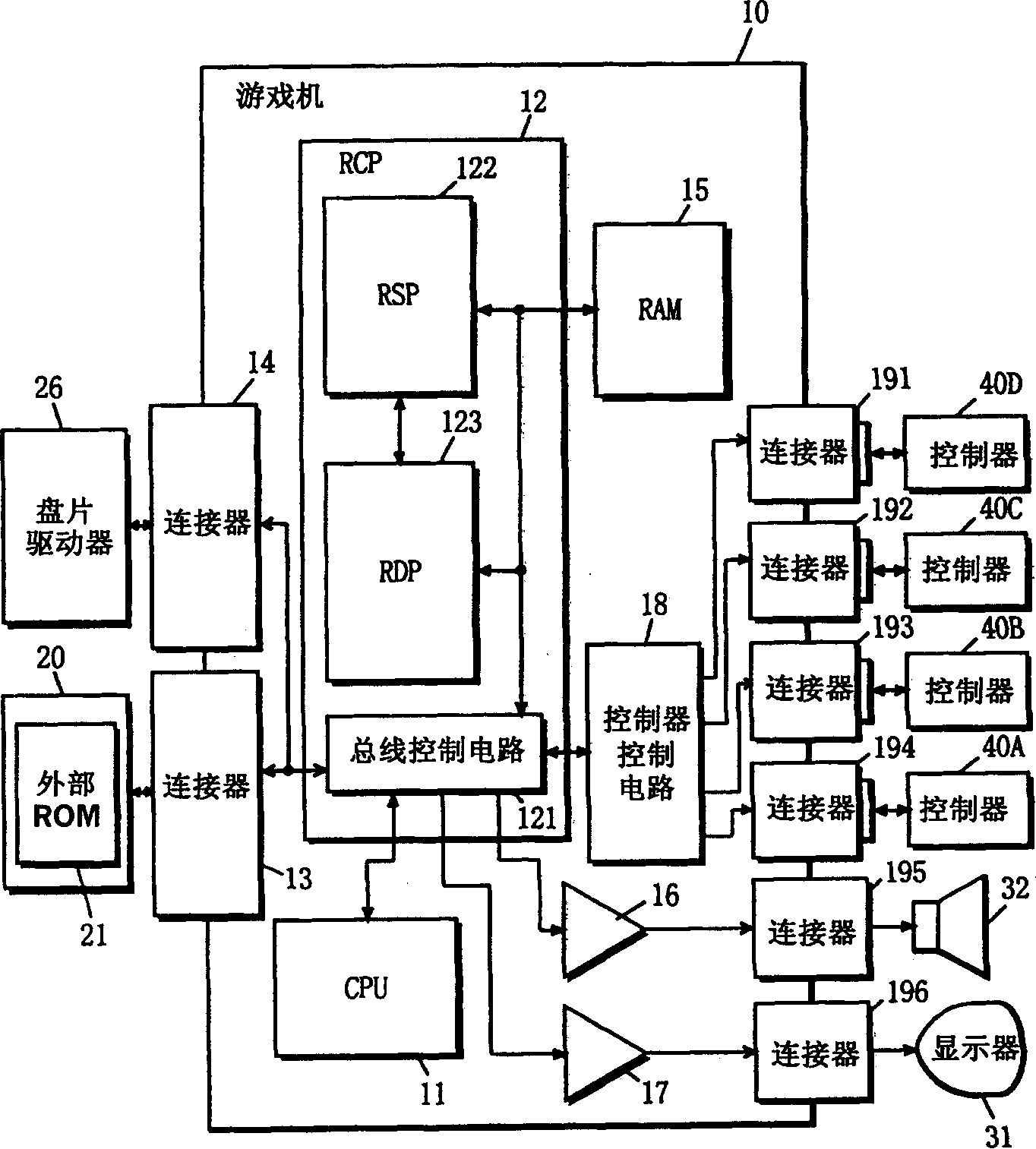

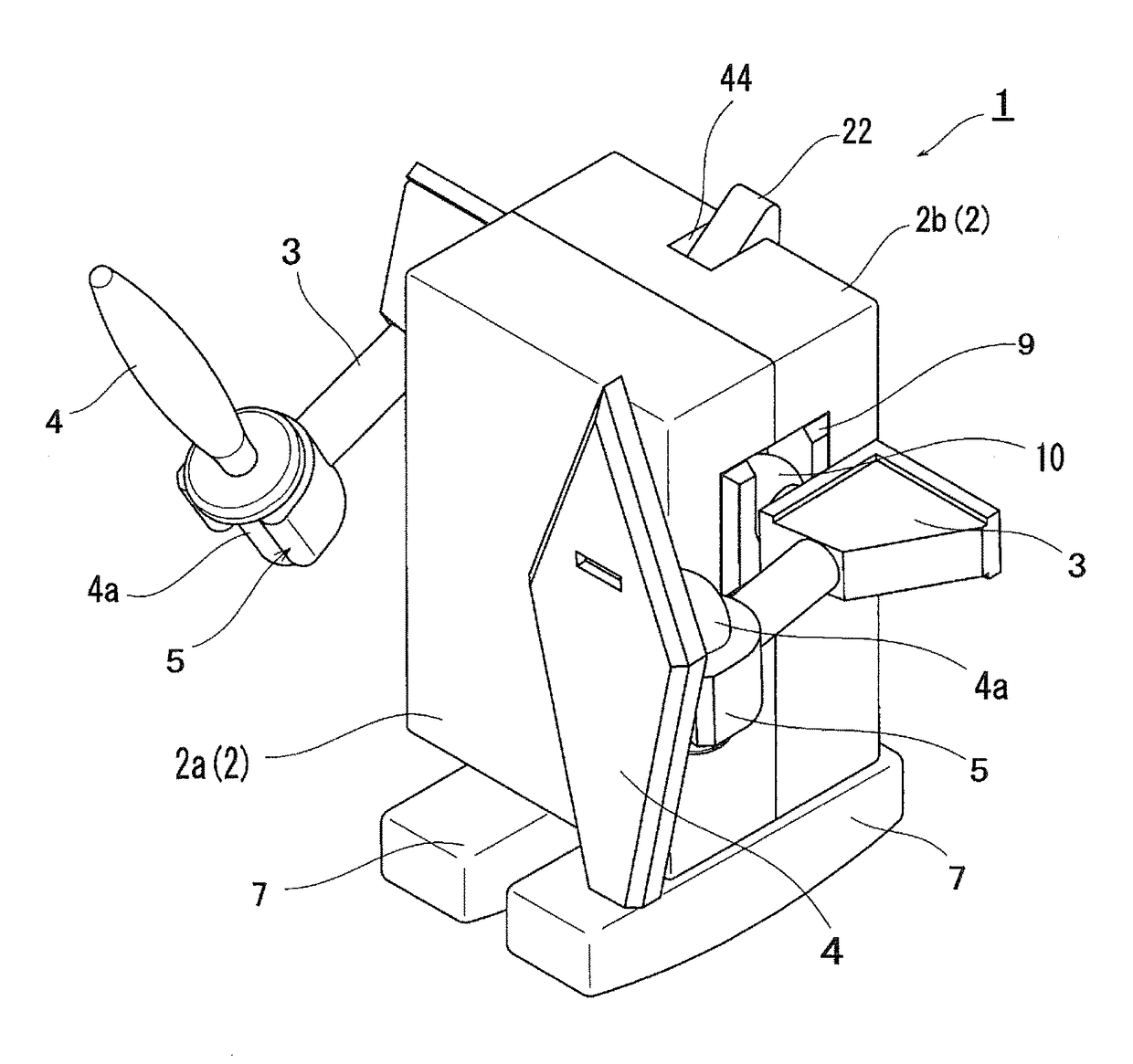

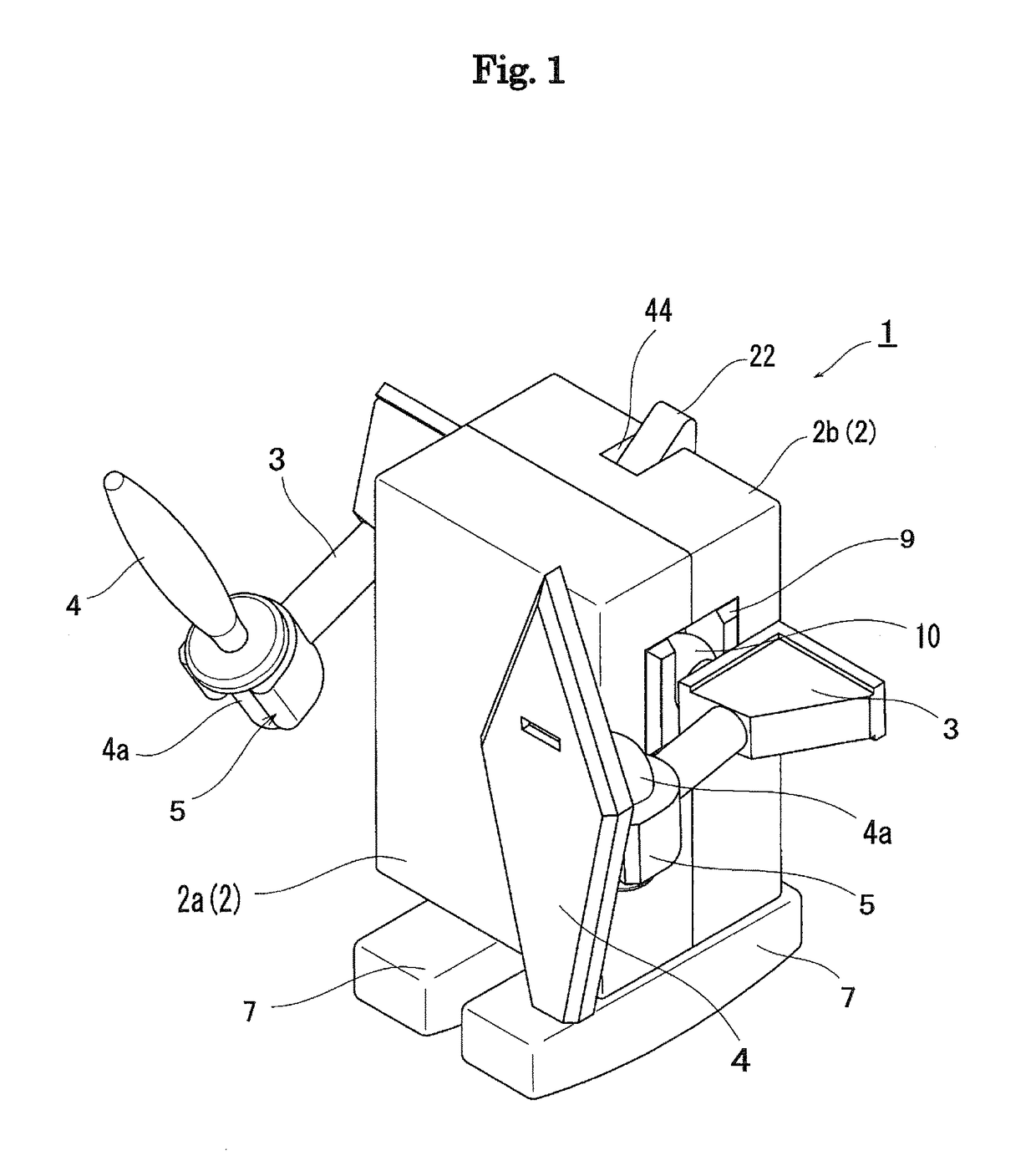

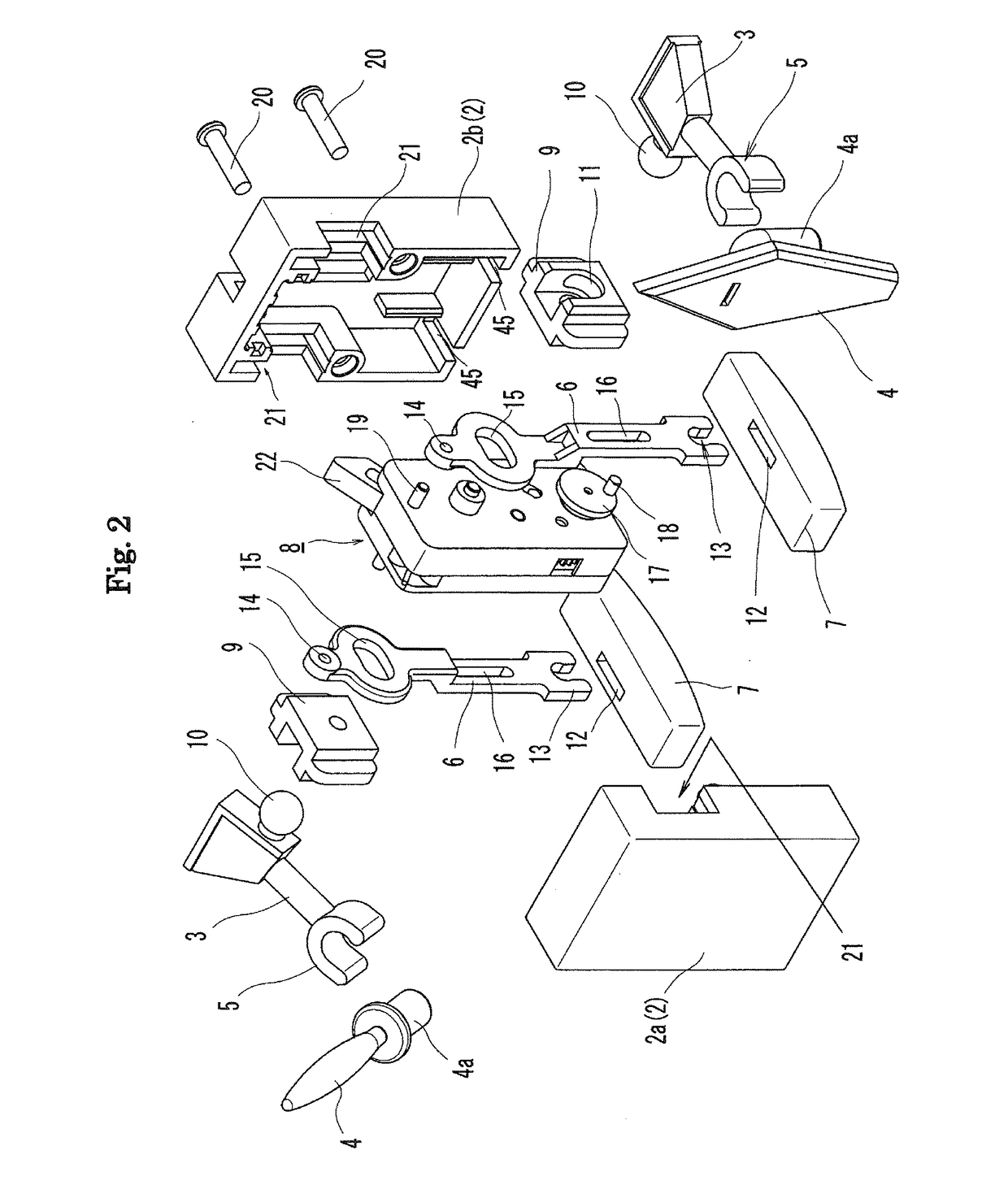

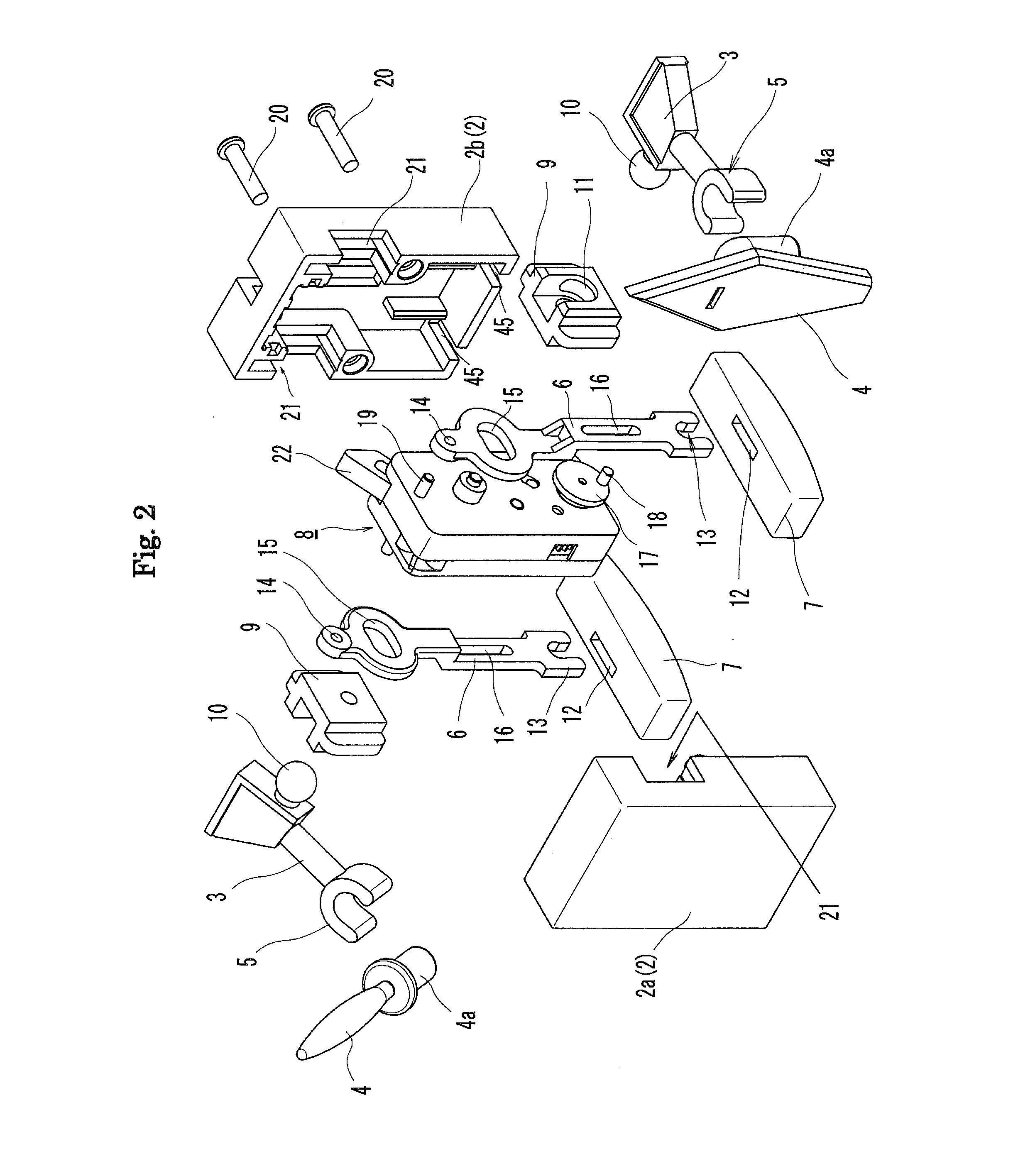

Sound generator and video game machine employing it

InactiveCN1279803ARich soundEasy to adjustElectrophonic musical instrumentsVideo gamesJoystickData storing

When any of push-button switches on a controller 40 is pressed in a sound input mode, a video game machine body 10 generates and temporarily stores frequency data of a tone corresponding to the pressed switch. At this time, when a joystick 45 on the controller 40 is tilted to a predetermined direction, the video game machine body 10 changes the generated frequency data according to the amount of tilt of the joystick 45. It is therefore possible to input various sounds in tone using a limited number of switches. The frequency data stored in the video game machine body 10 is read later to be converted into audio signals, and outputted from a speaker incorporated in a CRT display 30. When a melody based on the inputted sound coincides with a melody set in advance, the video game machine body 10 makes various changes in the progress of the game. For example, a hero character is warped to a position that is different from the present position, or provided with various items.

Owner:NINTENDO CO LTD

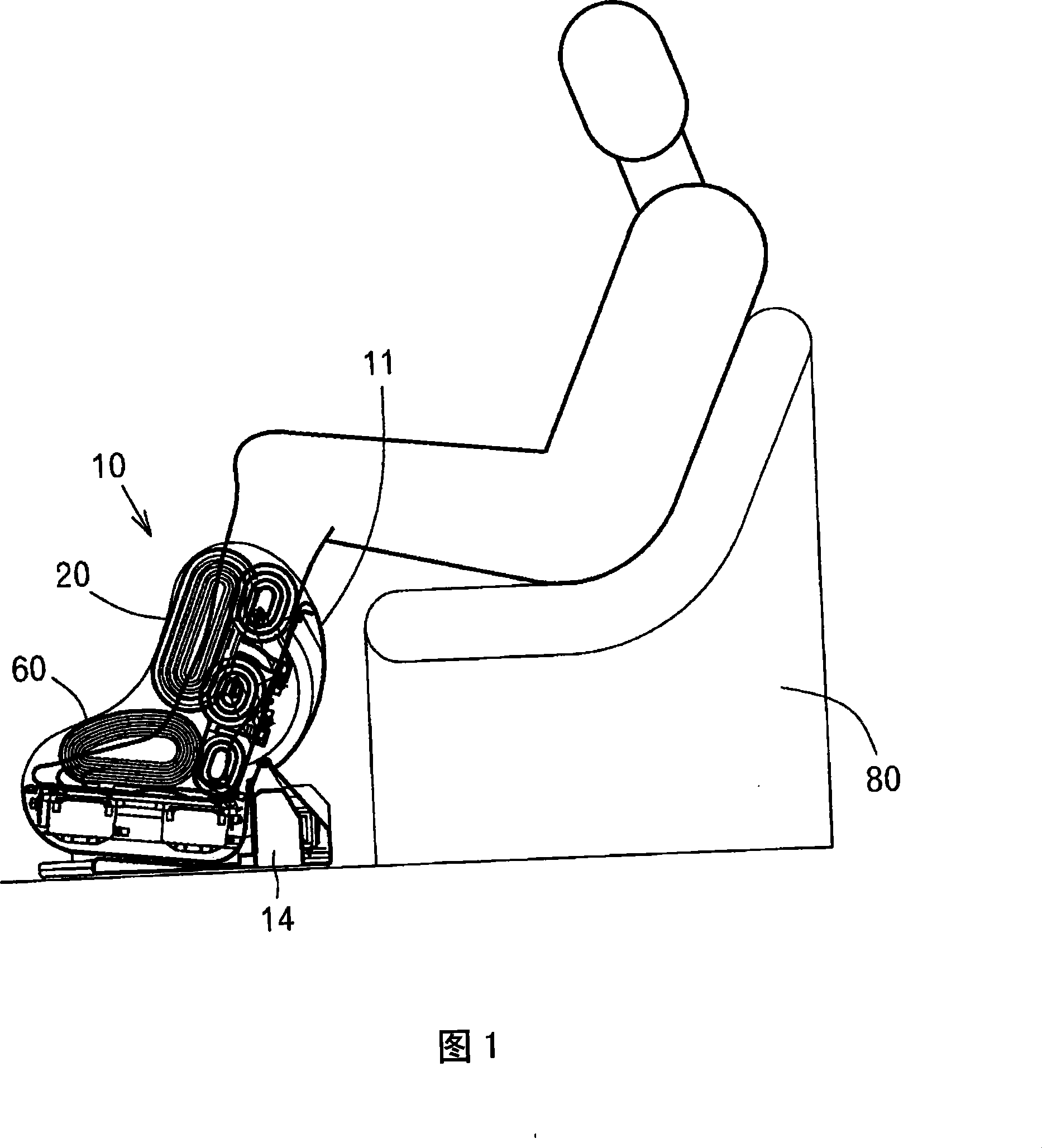

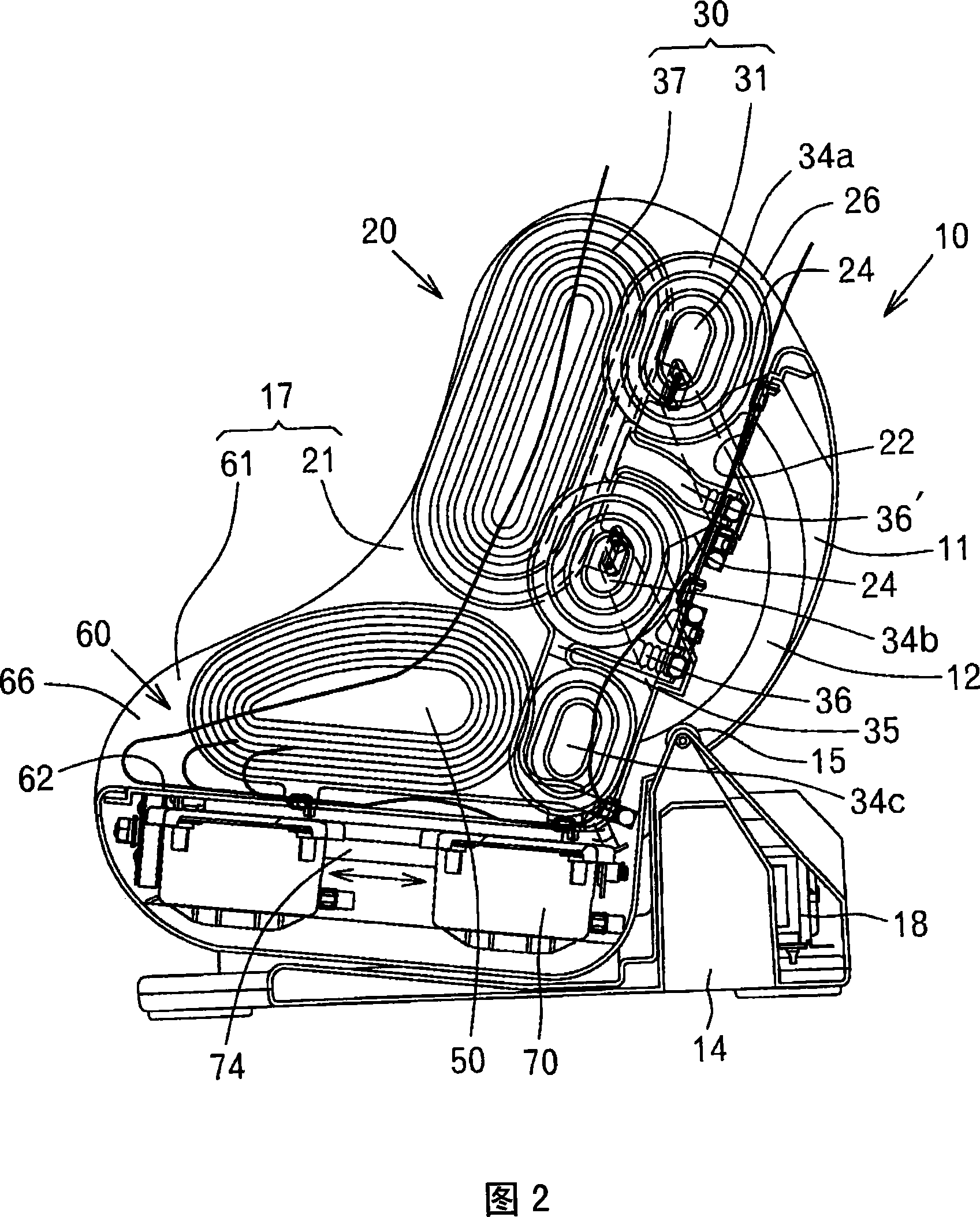

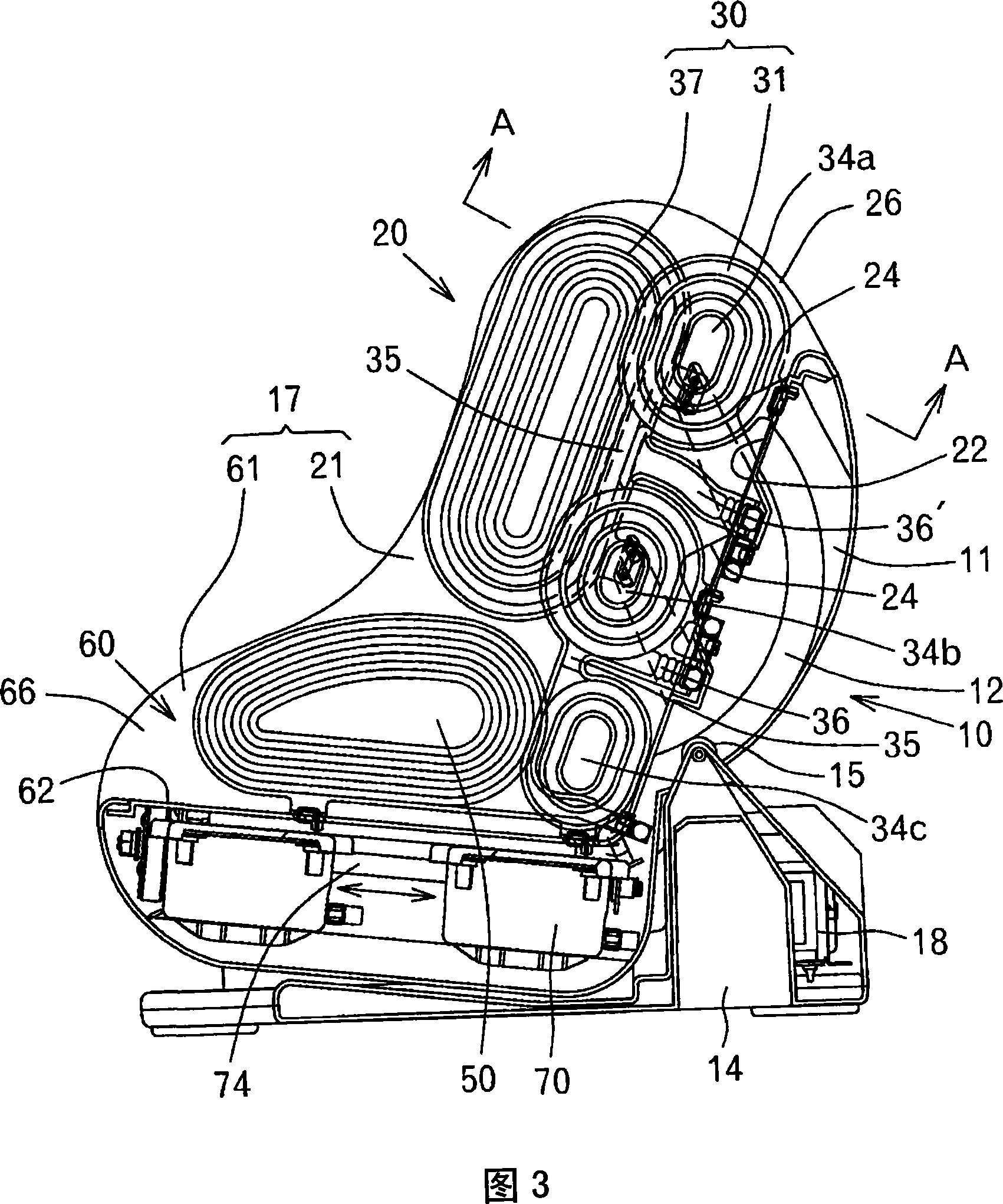

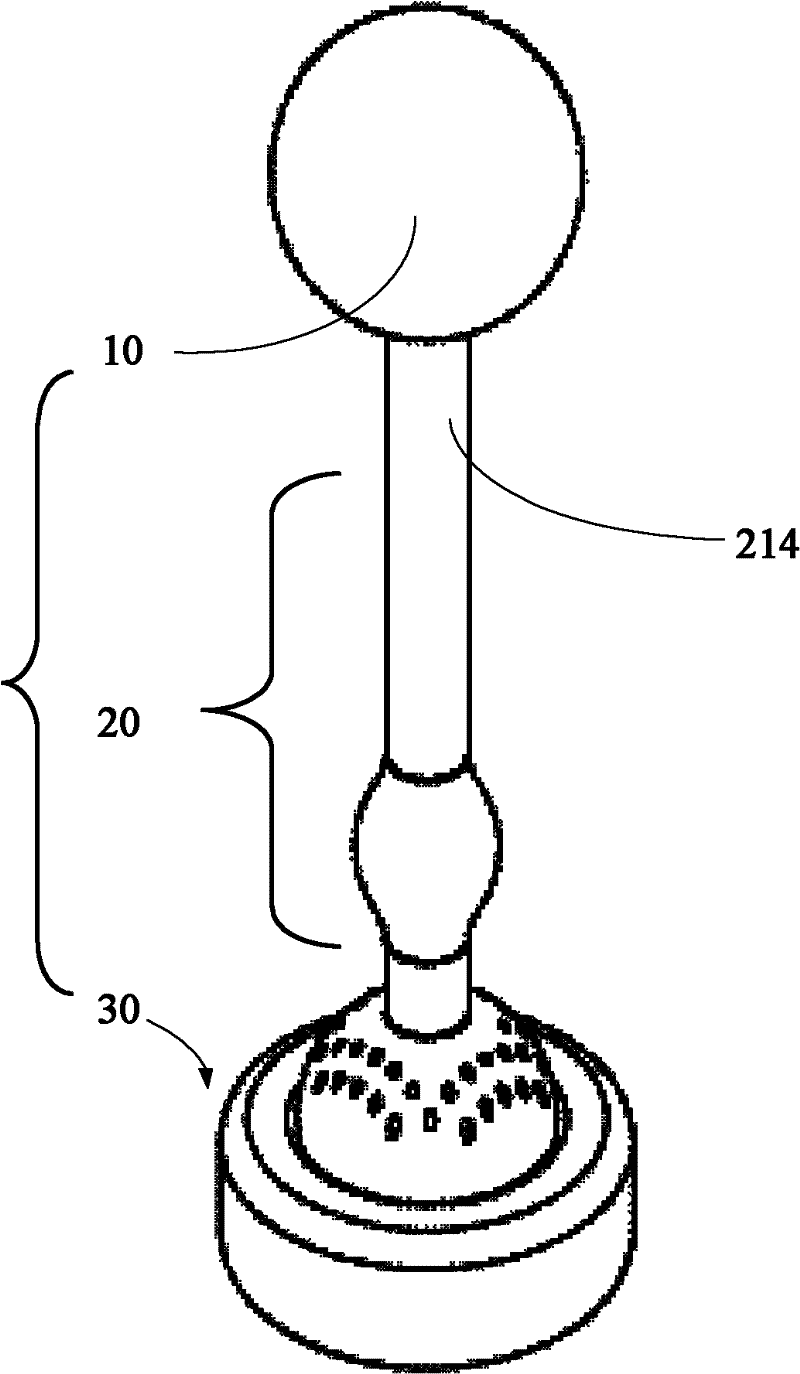

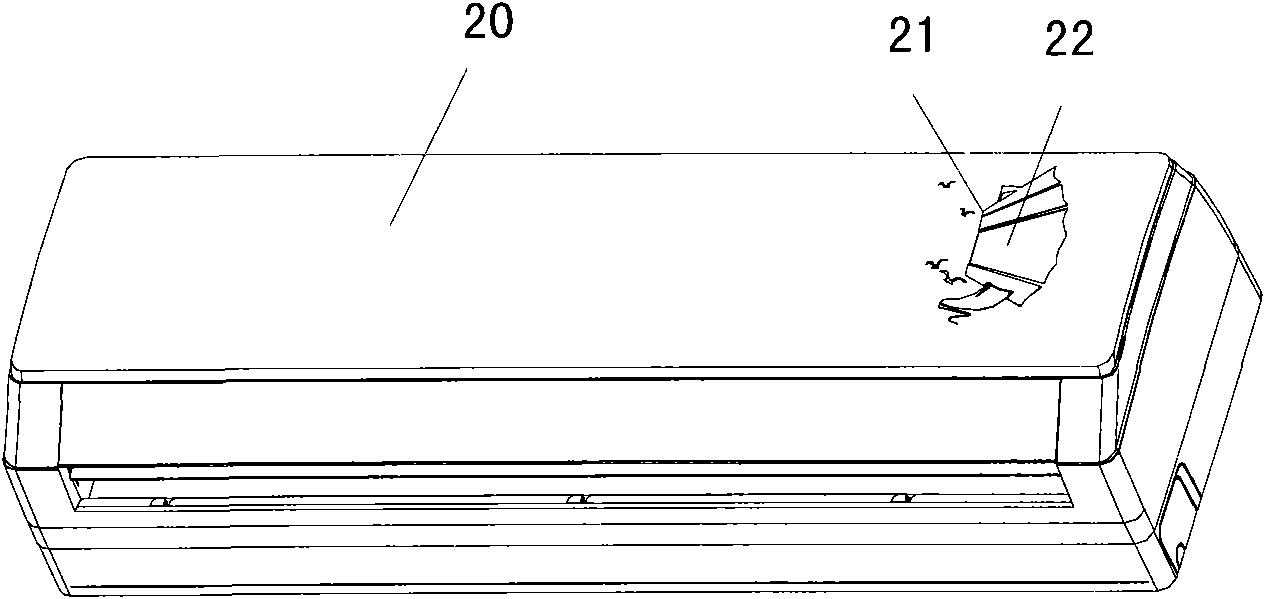

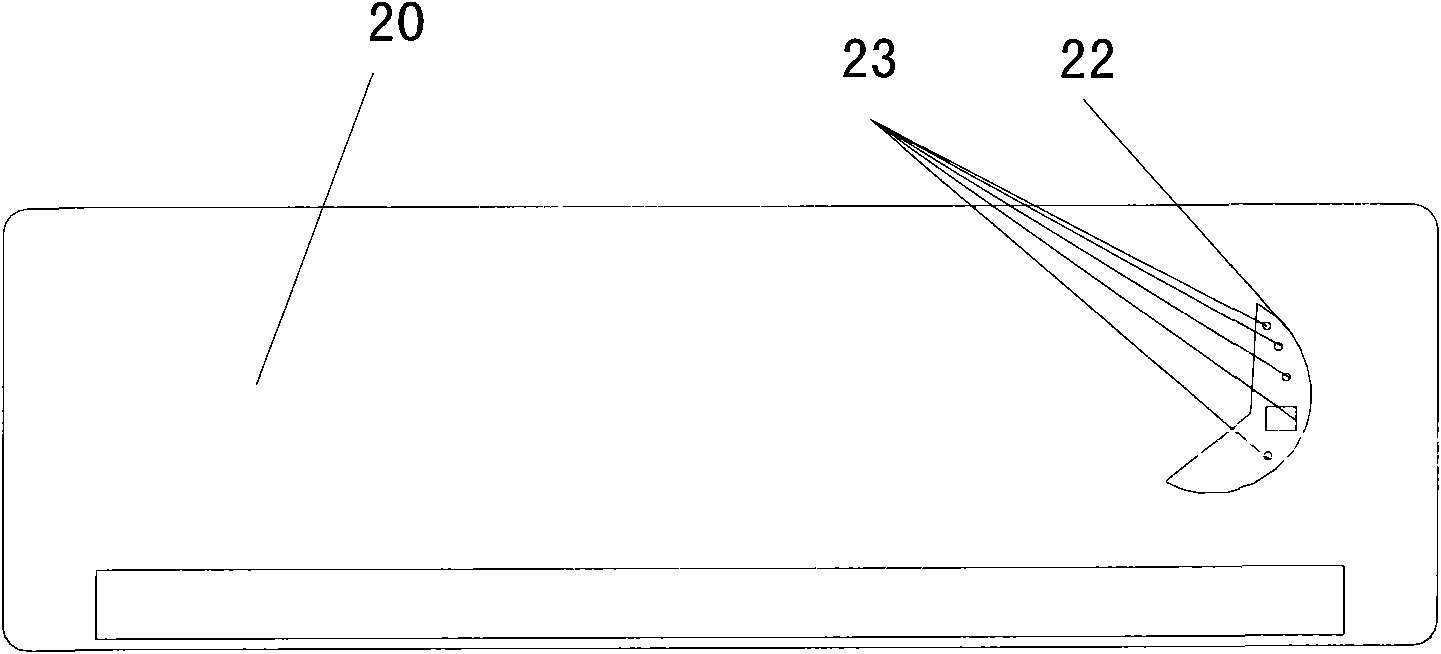

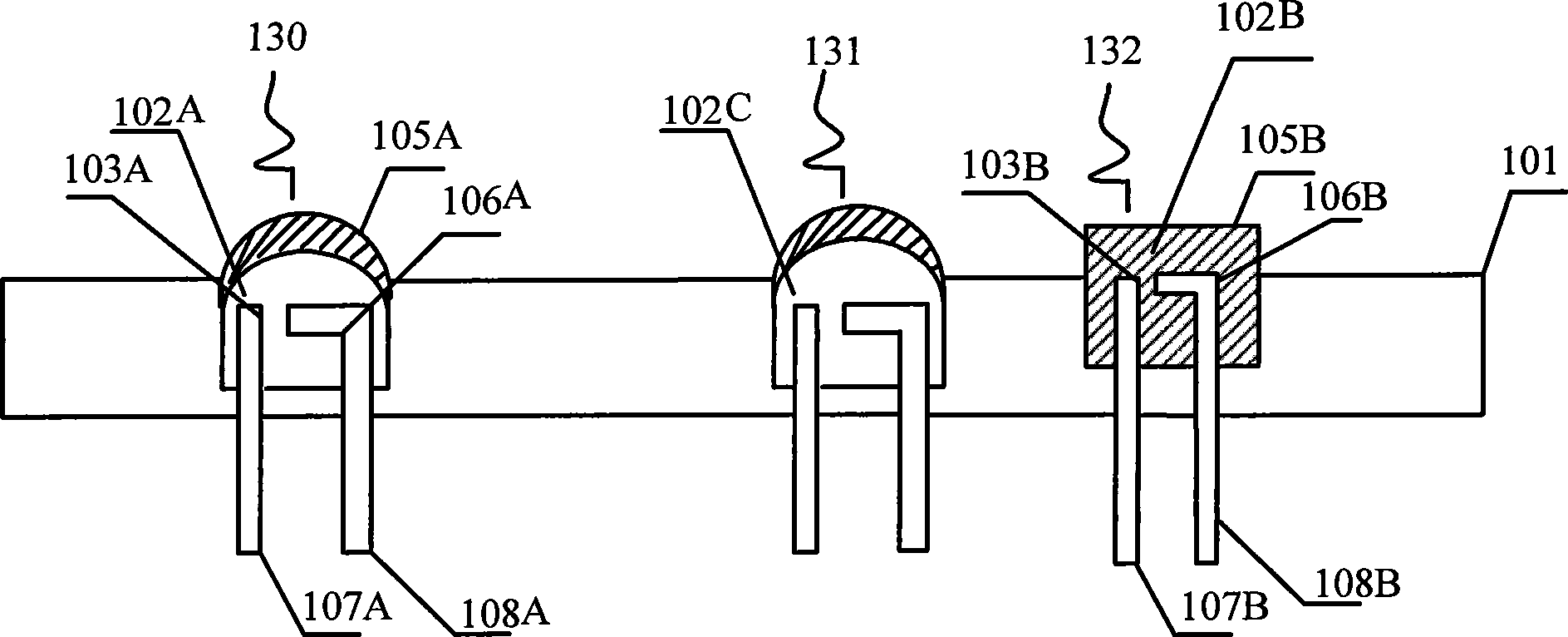

Massaging unit for calf

InactiveCN101190162AAccurate and effective massageRich in changeSuction-kneading massageMassageSurgery

The invention provides a calf massage unit which improves the massage effect with air bags and applies various massages. The unit is provided with a pair of left and right concave parts (21 and 21) for containing patient's calf, a side air bag (30) arranged on the side stretching upward from the base (22) of each concave part along the left and right direction. The side controls the expansion and the shrinkage of the air bag to massage the calf. Wherein, the side air bag (30) compromises: a first air bag (31) arranged on a base side of the concave part side; and a second air bag (37) arranged on an opening side of the concave part side. The first air bag massages the rear side of the calf from the calf side, and the second air bag massages the front side.

Owner:SANYO ELECTRIC CO LTD

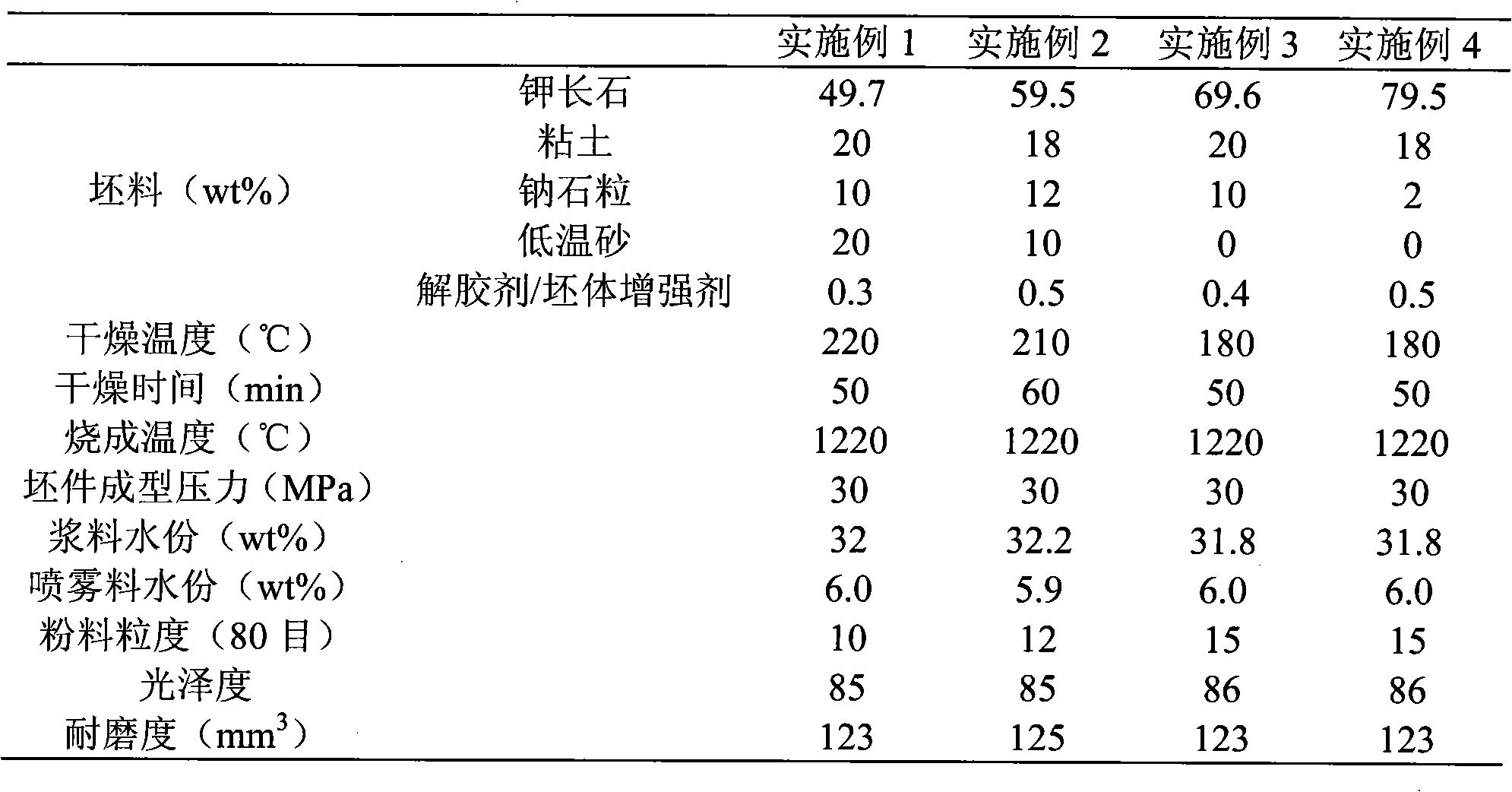

Jade texture semi-transparent ceramic material and production method thereof and application

The invention discloses a jade texture semi-transparent ceramic material; the material is formed by the following constituents by mass percentage: 40-90 percent of potash feldspar, 10-25 percent of clay and 0-40 percent of sodium particles or low-temperature sands. The invention also discloses a production method of the jade texture semi-transparent ceramic material and the application. The texture of the jade texture semi-transparent ceramic material is fine and smooth and patterns thereof have strong three-dimensional sense, and hardness, glossiness and transparence are better compared withcommon transparent ceramic material, therefore, the ceramic material is suitable for architectural ornament.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

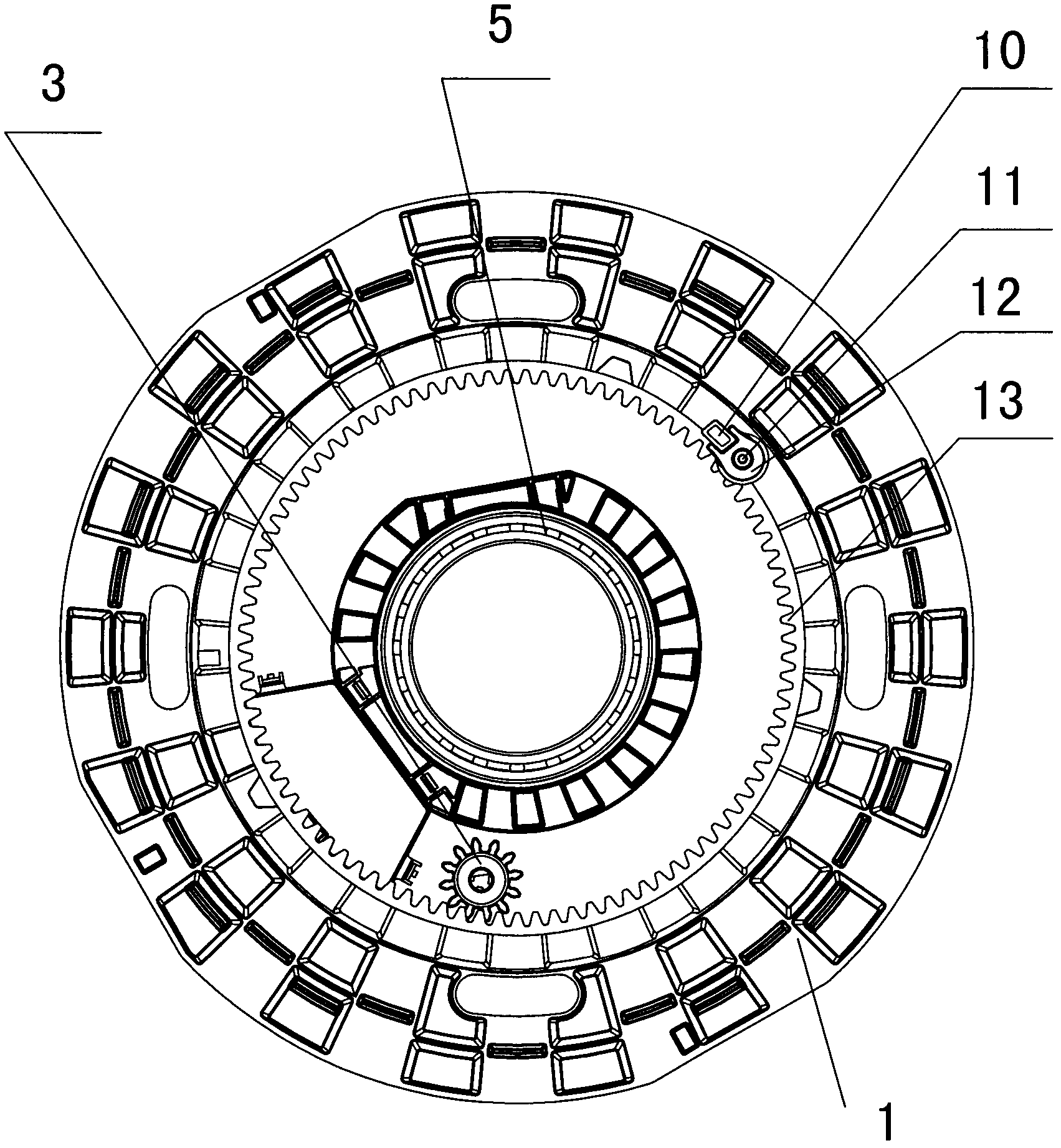

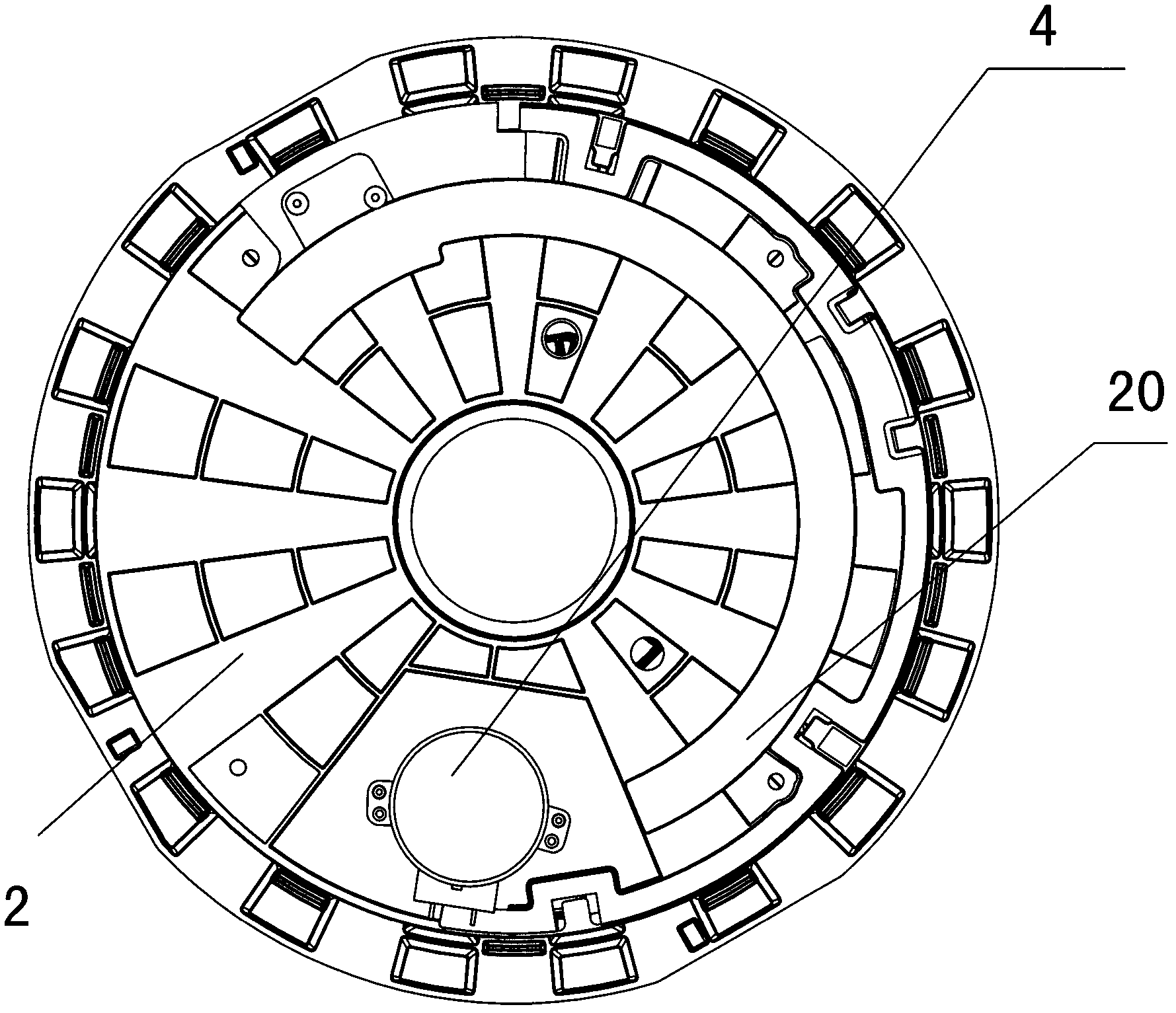

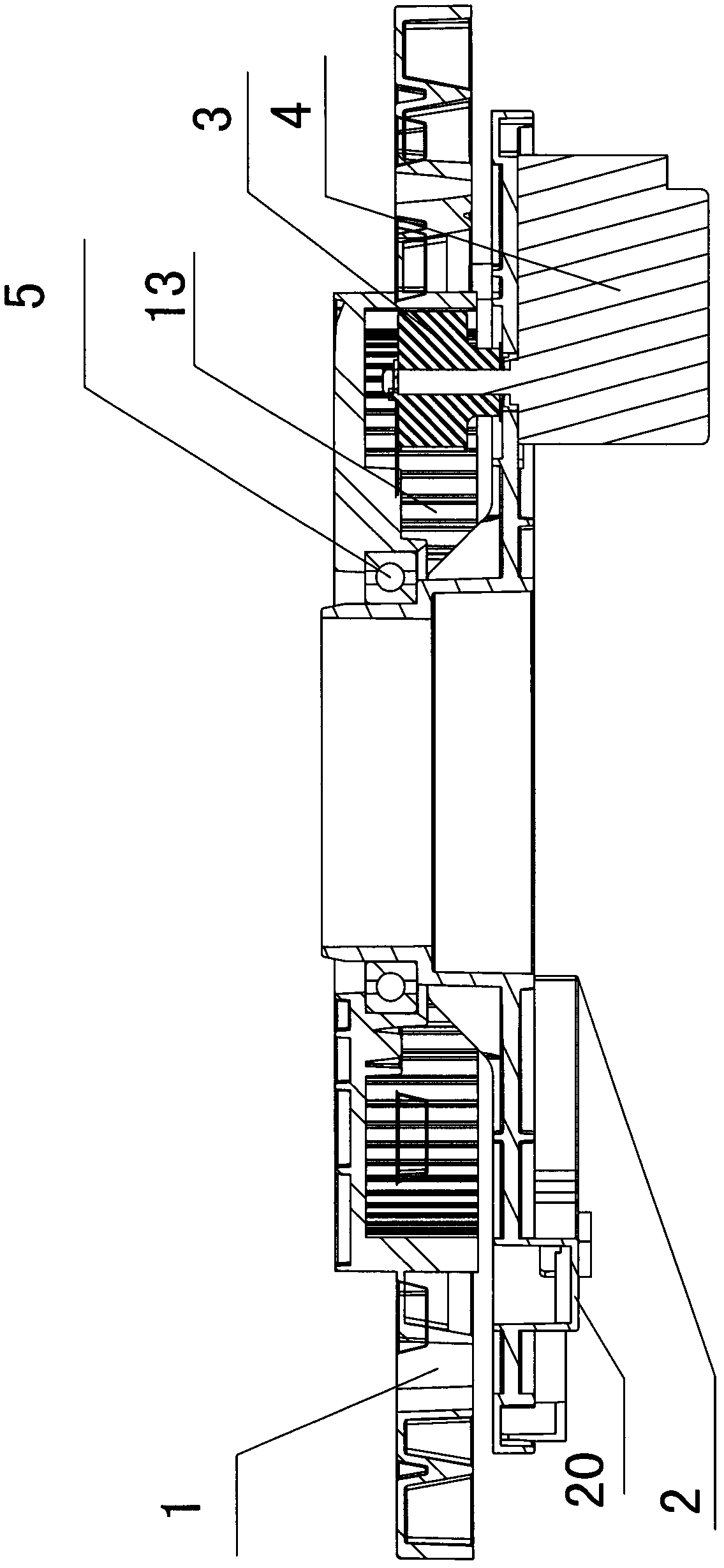

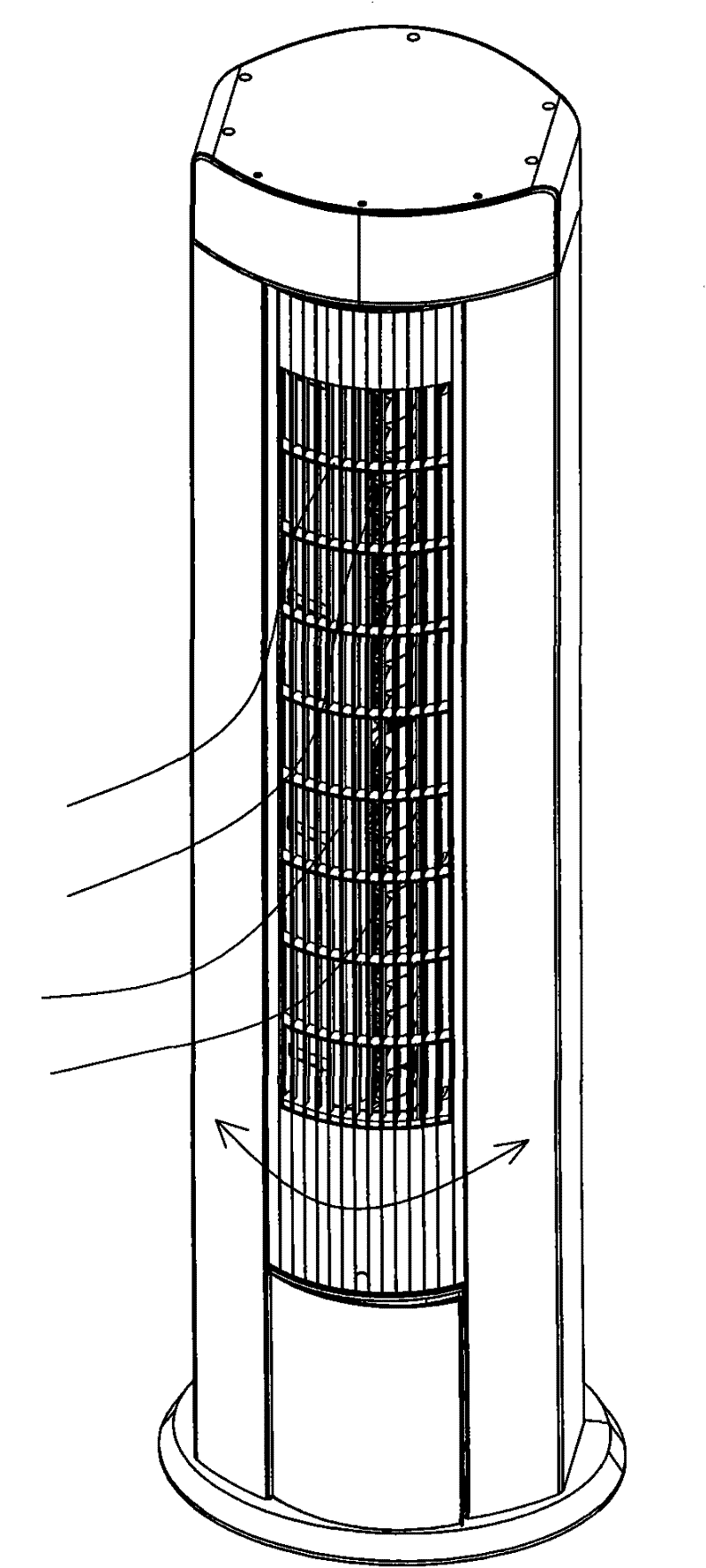

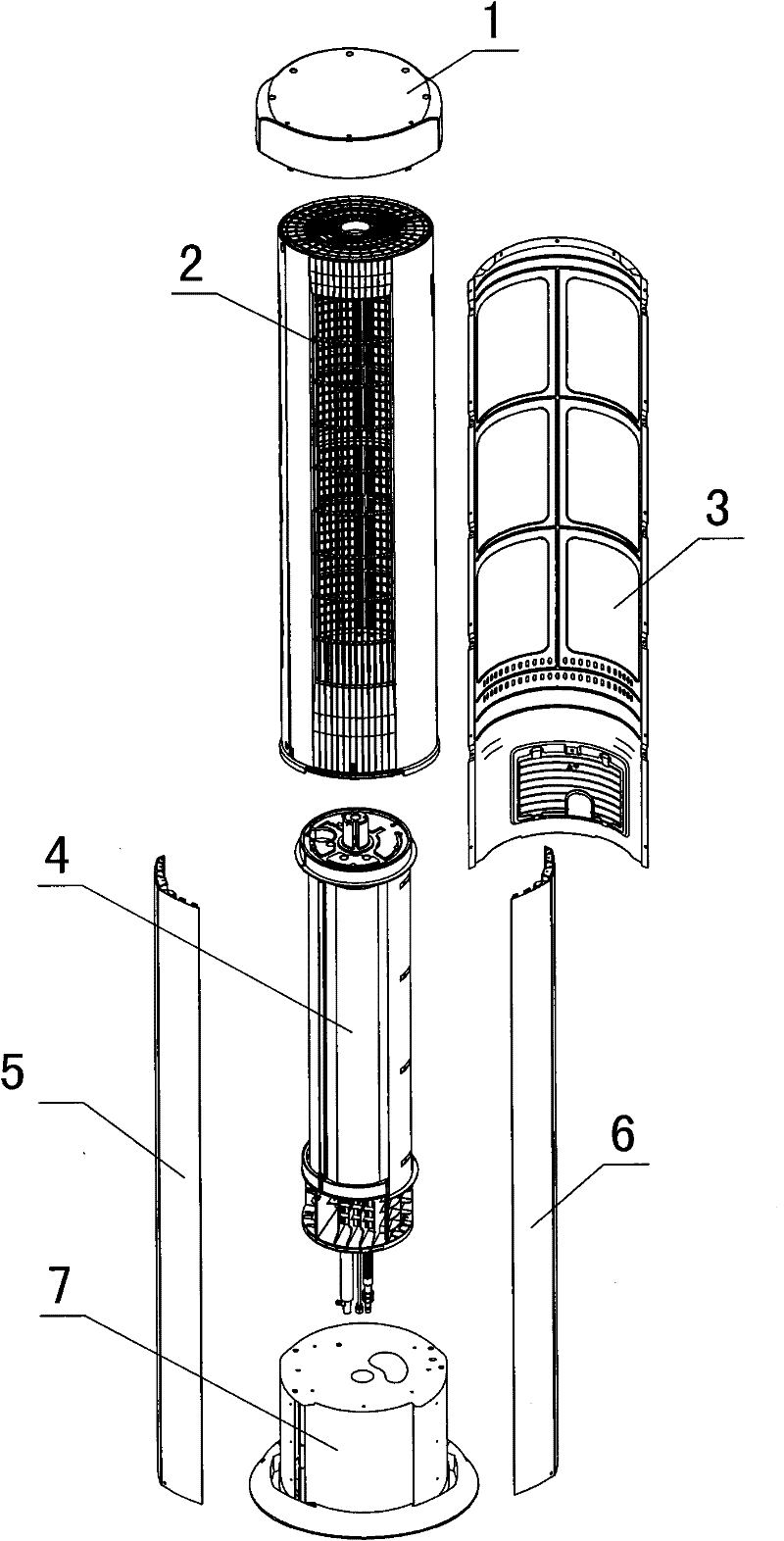

Vertical air conditioner

ActiveCN102466274ANovel structureSmooth rotationLighting and heating apparatusNon-rotating vibration suppressionEngineeringMoving parts

The invention provides a vertical air conditioner. The outer unit housing of the vertical air conditioner cannot shake during startup, shutdown and rotation and moves stably. The vertical air conditioner comprises a main body part and a base component and has a columnar structure integrally, wherein the main body part comprises the outer unit housing; the bottom of the outer unit housing is arranged on the base component by a moving part in a rotatable manner; the moving part is provided with a damping slider device which can ensure the stable movement of the outer unit housing; the base component comprises a motor mounting seat, and a stepping motor is fixed on the motor mounting seat; the moving part comprises an inner fluted disk which has a disk shape integrally, and the outer unit housing is fixed on the inner fluted disk; the middle part of the inner fluted disk is matched with the middle part of the motor mounting seat by a plastic bearing; and the damping slider device is a rubber damping block, an arc chute is formed on the motor mounting seat, and the rubber damping block is fixed on the inner fluted disk and slides in the arc chute.

Owner:GREE ELECTRIC APPLIANCES INC

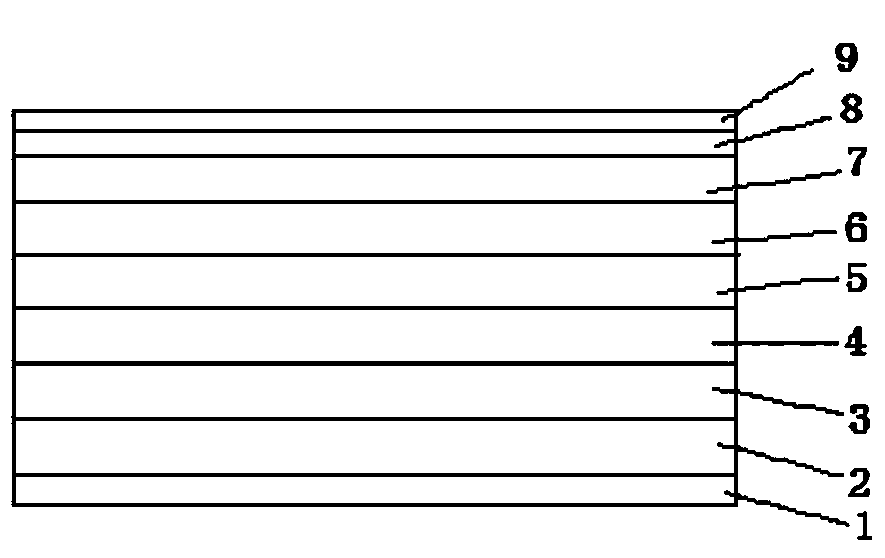

Color-changeable antibacterial and environment-friendly wallpaper

ActiveCN104074100AFlame retardants haveAntistatic agent hasCoatings with pigmentsCovering/liningsMoisture absorptionAnti bacteria

The invention provides color-changeable antibacterial and environment-friendly wallpaper. The color-changeable antibacterial and environment-friendly wallpaper comprises a base layer, wherein the back face of the base layer is provided with a waterproof coating; a coating layer is arranged on the base layer; a bamboo charcoal fiber layer is arranged on the coating layer; an inflaming retarding layer is arranged on the bamboo charcoal fiber layer; a printing embossing layer is arranged on the inflaming retarding layer and is coated with a color-changeable layer; the color-changeable layer is provided with an anti-scratching layer; the anti-scratching layer is provided with a film coating layer. The wallpaper is provided with the bamboo charcoal fiber layer so that the wallpaper has the advantages of moisture absorption, ventilation, bacteria inhibition and resistance and the like; the inflaming retarding layer and the anti-scratching layer are arranged so that the fire resistance and the anti-scratching capability of the wallpaper are increased; the color-changeable layer is arranged so that the wallpaper can change colors along the change of indoor temperatures, so that the wallpaper is diversified, indoor decoration is rich in change, and the interestingness and the beautification are greatly enhanced.

Owner:TAICANG SANYI HEATING & CHILLING PROJECT CO LTD

Temperature-sensitive printed wall cloth manufacturing technology

InactiveCN103334248AThe production process is simpleThe manufacturing process is easy to controlSucessive textile treatmentsCovering/liningsSizingPrinting ink

The invention discloses a temperature-sensitive printed wall cloth manufacturing technology which includes the following steps that firstly, warp yarn and weft yarn are woven in a crossed mode to form base cloth; secondly, the base cloth undergoes sizing and size is macromolecular liquid of demulsibility; thirdly, after the base cloth undergoes sizing, the front of the base cloth undergoes first coating processing; fourthly, the front of the base cloth undergoes coating processing again and coating liquid is reversible temperature-sensitive printing ink; fifthly, the back of the base cloth undergoes second coating processing; sixthly, the base cloth undergoes second drying processing. With the manner, the temperature-sensitive printed wall cloth manufacturing technology is easy to operate and control. Wall cloth manufactured with the technology is capable of changing colors along with variation of temperature, good in waterproofness, friendly to environment and free of foams and mildew. The wall cloth is rich in variation as the patterns of the wall cloth vary along with different contacted portions.

Owner:WUJIANG LONGFANG TEXTILE

Manufacturing process for archaistic wood floor

InactiveCN108381725AStrong three-dimensional senseUniform depthNatural patternsRosin coatingsPulp and paper industryHue

The invention relates to a manufacturing process for an archaistic wood floor. The manufacturing process comprises four manufacturing processes including a base material processing process, a wood bark processing process, a chemical change treatment process and an archaistic process; the manufacturing process provided by the invention can be used for implementing batch production of archaistic wood floors and can obtain the archaistic wood floors which have water resistance, corrosion resistance and worm damage resistance; the ageing degree of the floors can be regulated by regulating the soaking time; the archaistic wood floors with various colors and various stripes can be manufactured; the stripes on the archaistic wood floors are uniform enough in depth, high in stereoscopic impressionand full of changes; the naturally shown hue is archaistic and the texture is clear.

Owner:湖州市南浔广达木业有限公司

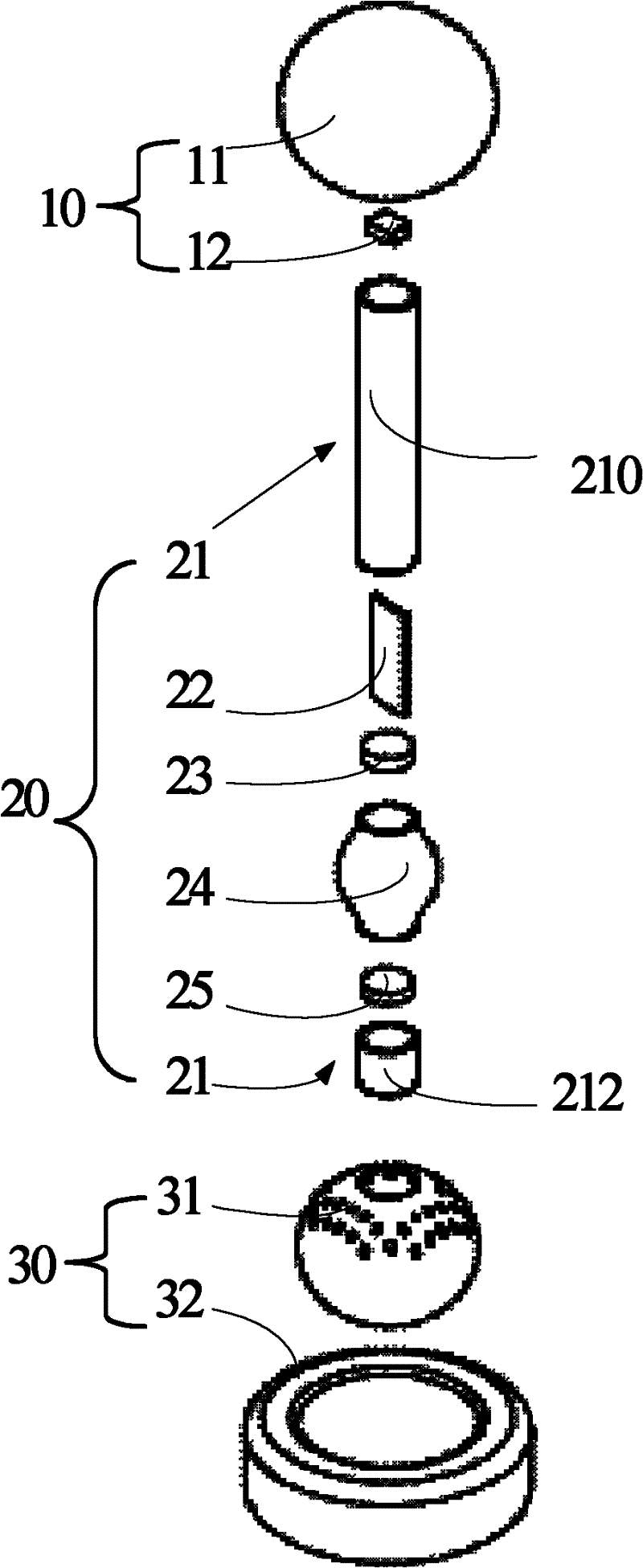

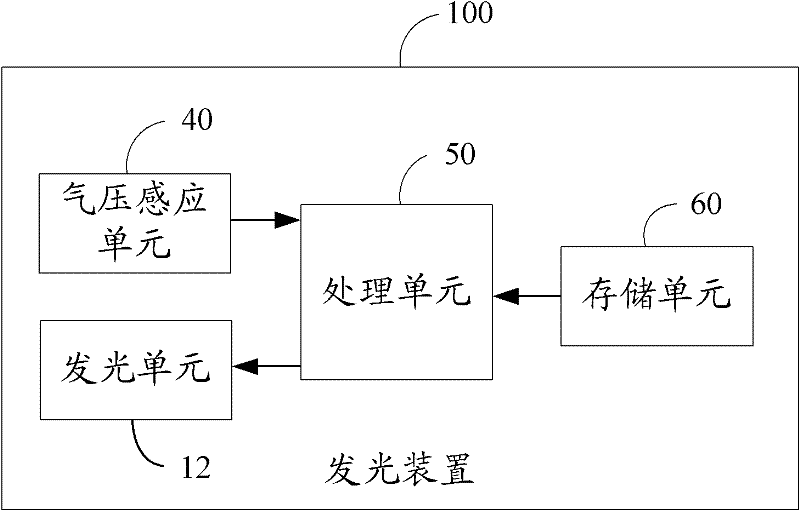

Light-emitting device and light emission control method thereof

InactiveCN102333396ARich in changeInterestingElectrical apparatusElectroluminescent light sourcesInternal pressureAtmospheric pressure

The invention provides a light-emitting device and a light emission control method. The light emitting device comprises a light emitting unit used for emitting light with different colors and brightness. The light emission control method is used for the light emitting device and comprises the steps of sensing an internal pressure value and controlling the light emitting unit to emit light with corresponding color and brightness according to the pressure value.

Owner:FU TAI HUA IND SHENZHEN +1

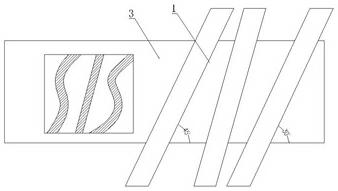

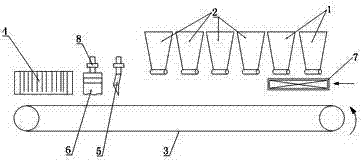

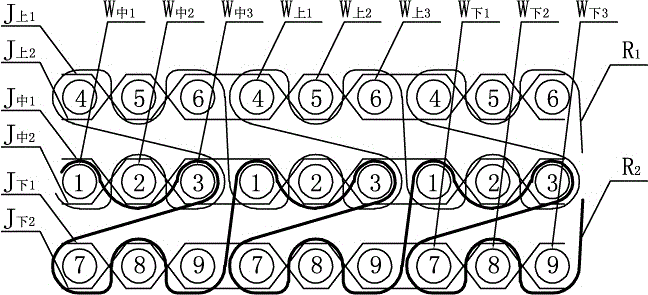

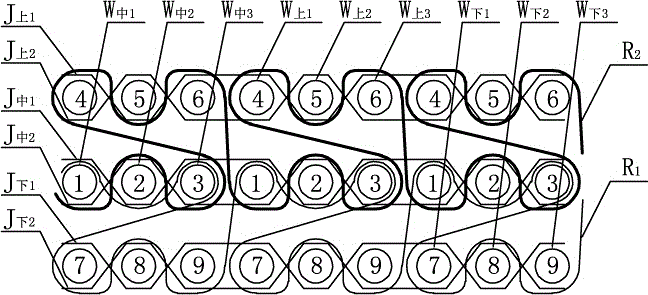

Material distribution device and method for polished tiles

ActiveCN103273557AEasy to operateRich in changeFeeding arrangmentsShaping conveyorsStructural engineeringMaterial distribution

Disclosed are a material distribution device and method for polished tiles. The material distribution device comprises a material distribution hopper, a main conveyor belt, a front material collecting box and a back material collecting box, wherein the material distribution hopper, the front material collecting box and the back material collecting box are sequentially arranged along the movement direction of the main conveyor belt, the material distribution hopper is disposed above the main conveyor belt, the front and back material collecting boxes are horizontally arranged over the main conveyor belt in a closely attaching mode, the front material collecting box is a hexahedral box which is buckled inversely on the main conveyor belt, baffles are not arranged in front and below the front and back material collecting boxes, a back baffle of the back material collecting box is a gate capable of being lifted independently, and the front and back material collecting boxes are provided with drive devices capable of lifting the front material collecting box intermittently. According to the material distribution device and method, texture patterns on surfaces of ceramic tiles are clear and stable, a material distribution process of large-turn clear lines is achieved, line textures bending in different directions are produced, the textures are rich in change, random and natural, the presentation range of the ceramic tiles is expanded, and the wide practicability is provided.

Owner:QINGYUAN NAFUNA CERAMICS +2

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804654BEasy surface modificationReduce energy consumptionLiquid surface applicatorsWood veneer joiningSolid woodPulp and paper industry

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: processing a surface board, processing a core board, processing a base board, glue pressing and compounding, fine processing, coating the surface, and forming the finished product. The process has the advantages of strong natural visual sensation, comfortable foot sensation, good material quality, easy processing, cyclic utilization, good geothermy adaptability, strong stability, more simple and convenient construction and installation, excellent environmental performance, great increase of comprehensive utilization ratio of timbers and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

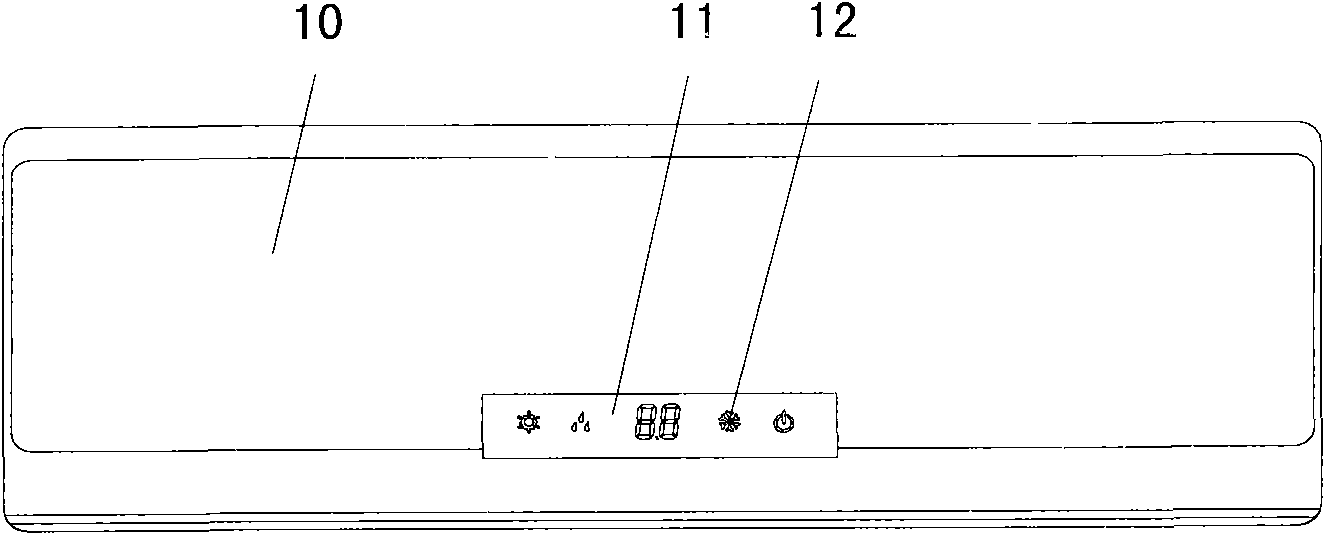

Air conditioner with display device

ActiveCN101614435ADisplay clearImprove the display effectSpace heating and ventilation safety systemsLighting and heating apparatusDisplay boardDisplay device

The invention provides an air conditioner with a display device capable of being combined with patterns, comprising a panel, the display device and a control circuit. The panel is provided with a pattern area which is an integral picture comprising a plurality of pattern elements; and a through hole in a shape identical to the outer contour of part or all pattern elements is arranged in the pattern area. The display device comprises a display board and a light source; the display board can be mounted in the through hole in a shape identical to the outer contour of part or all pattern elements in the pattern area; the light source is arranged at the back of the display board; and electrodes of the light source are electrically connected with the control circuit or directly and electrically connected with the light source. The display device has clear display and rich and vivid display colors and contents rich in variety.

Owner:GREE ELECTRIC APPLIANCES INC

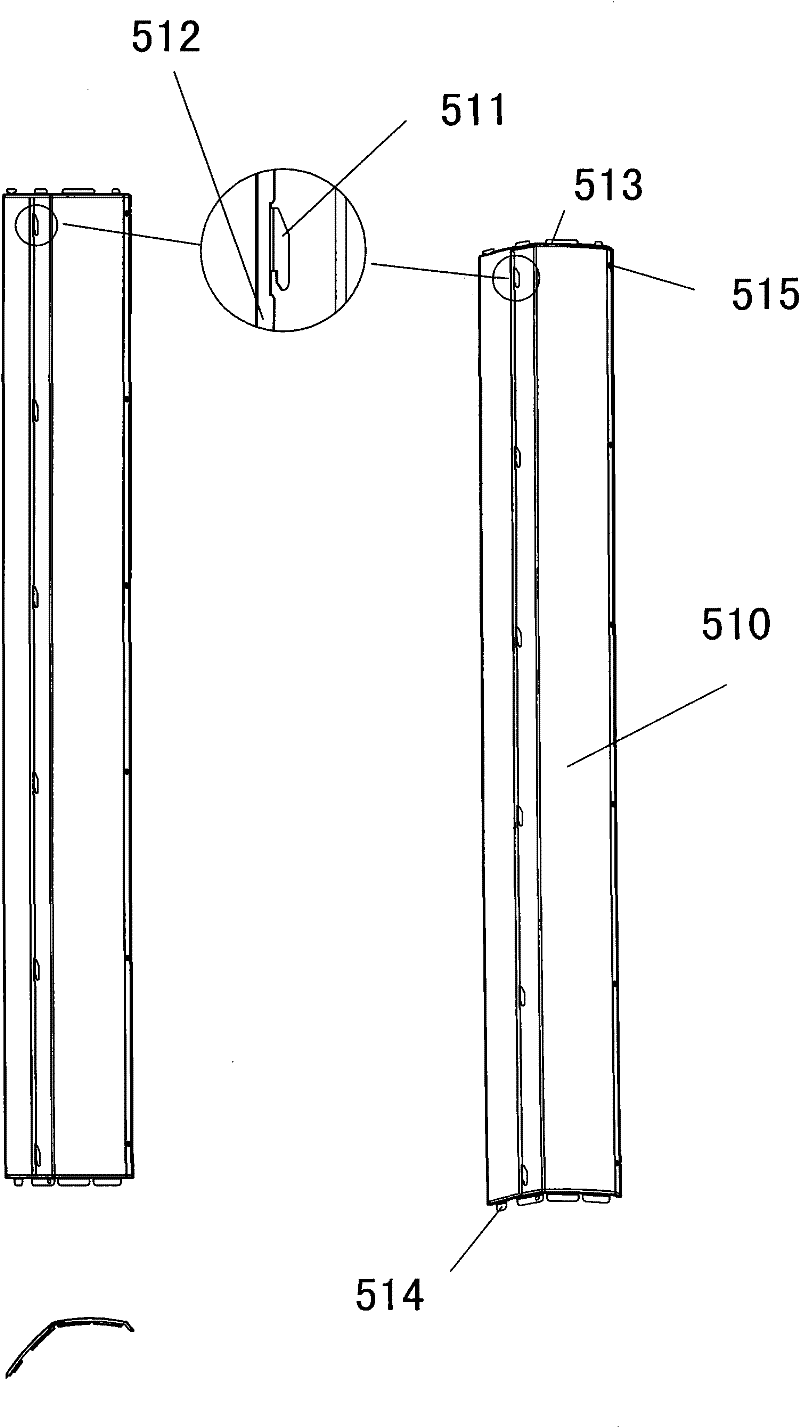

Floor air conditioner

InactiveCN102478301AStable structureNovel structureLighting and heating apparatusHeating and ventilation casings/coversEngineeringMoving parts

The invention discloses a floor air conditioner, which is convenient to assemble, good in structural strength and greatly improved in the stability of an entire unit. The invention is realized by means of a technical scheme as follows: the floor air conditioner comprises a main body part and a base part, wherein the main body part comprises an outer enclosure and a rotation part; the bottom of the rotation part is rotatably arranged on the base part through a moving part; the floor air conditioner is of a columnar structure in total; an air duct is arranged inside an inner cavity of the rotation part; the outer enclosure comprises a left side plate part, a right side plate part, a rear plate and a top cover part; and the top cover part is fixed above the left side plate part, the right side plate part and the rear plate, the left side and the right side of the rear plate are respectively used for fixing the left side plate part and the right side plate part, and the left side plate part, the right side plate part and the rear plate are all fixed on the base part; and the left side plate part and the right side plate part are of a mutually symmetrical structure.

Owner:GREE ELECTRIC APPLIANCES INC

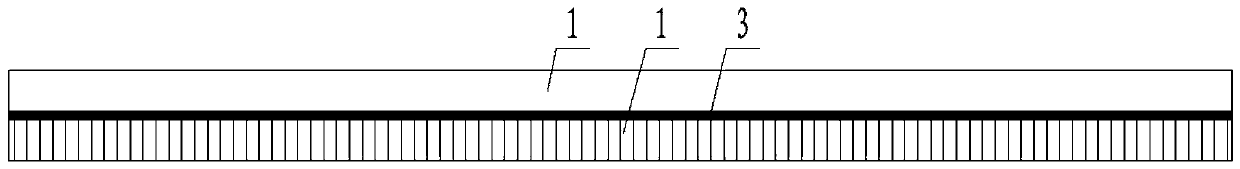

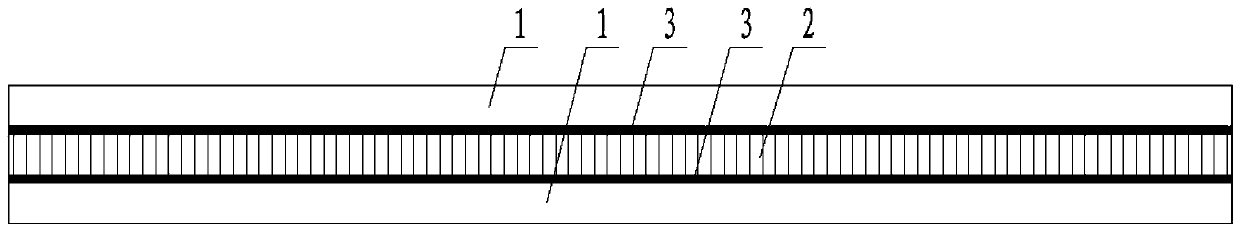

A green bamboo-wood composite board and its processing technology

The invention discloses a greenness-reserved bamboo-wood composite board. The greenness-reserved bamboo-wood composite board is of a single-face structure or a double-face structure. Each single-face structure is formed by bonding a greenness-reserved bamboo board and a refined wood board with glue. Each double-face structure is formed by bonding two greenness-reserved bamboo boards and a refined wood board with glue, wherein the refined wood board is arranged between the two greenness-reserved bamboo boards. The outer surface of each greenness-reserved bamboo board is a bamboo greenness face, and a layer of natural bamboo greenness is maintained on each bamboo greenness face. The greenness-reserved bamboo-wood composite board maintains original high hardness, high strength, good wear resistance and good corrosion resistance of the greenness-reserved bamboo board(s), and bamboo greenness of the greenness-reserved bamboo board(s) is reserved. The invention further discloses a processing technology of the greenness-reserved bamboo-wood composite board. The processing technology comprises the steps of selecting materials, conducting sawing-off, removing outer joints, removing inner joints, forming openings, conducting softening, conducting flattening, removing yellowness with the thickness fixed, conducting cooling for shaping, conducting drying at the low temperature, bonding the greenness-reserved bamboo board(s) with the refined wood board to form a greenness-reserved bamboo-wood composite board unit, conducting splicing, and bonding the greenness-reserved bamboo-wood composite board units to form the greenness-reserved bamboo-wood composite board. In the processing technological process, moso bamboo is softened, and no pollution is generated; in the drying process, the greenness-reserved bamboo boards are not deformed or cracked; and each bamboo greenness face maintains high hardness, flatness and smoothness.

Owner:浙江德长竹木有限公司

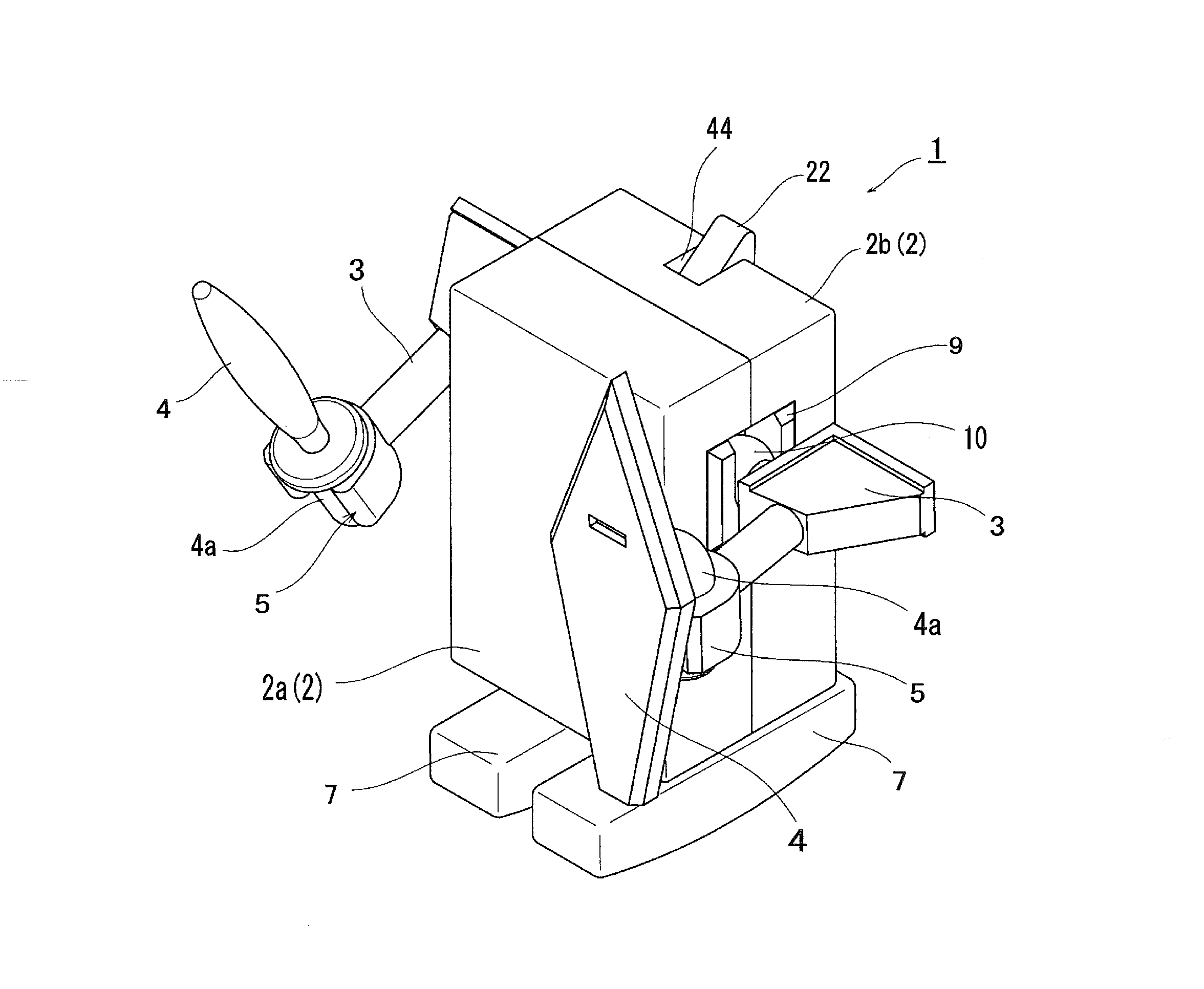

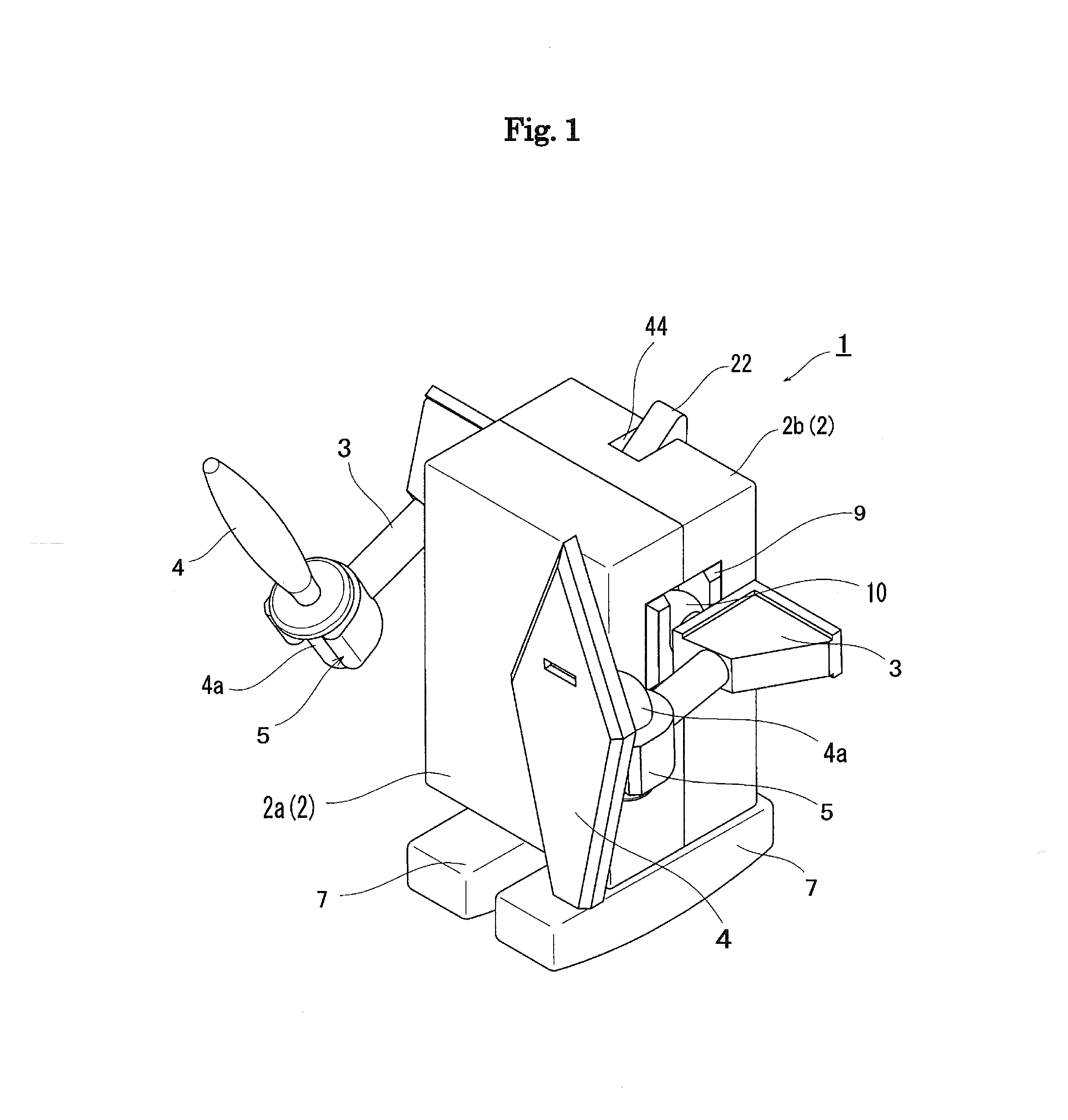

Walking toy and walking toy set

InactiveUS9675896B2Less liable to fall down during walkingEasilySelf-moving toy figuresToy gearsCoil springEngineering

A walking toy includes a body on which gravity center position adjusting members and paired legs are supported to be able to swing in a forward / backward direction, and a gearbox which has a crank mechanism for forcibly swinging the paired legs alternately forward and backward in a forcible swinging direction and which is mounted in the body. Each of the paired legs has a bottom which is configured to be in contact with a floor surface and which is formed into a curved face curved in the forcible swinging direction. The gearbox is driven by a torsion coil spring and has a lever which rotates a drive gear of a gear train for transmitting rotation of the torsion coil spring to an output shaft for rotating the crank mechanism.

Owner:MDWORKS

Greenness-reserved bamboo-wood composite board and processing technology thereof

The invention discloses a greenness-reserved bamboo-wood composite board. The greenness-reserved bamboo-wood composite board is of a single-face structure or a double-face structure. Each single-face structure is formed by bonding a greenness-reserved bamboo board and a refined wood board with glue. Each double-face structure is formed by bonding two greenness-reserved bamboo boards and a refined wood board with glue, wherein the refined wood board is arranged between the two greenness-reserved bamboo boards. The outer surface of each greenness-reserved bamboo board is a bamboo greenness face, and a layer of natural bamboo greenness is maintained on each bamboo greenness face. The greenness-reserved bamboo-wood composite board maintains original high hardness, high strength, good wear resistance and good corrosion resistance of the greenness-reserved bamboo board(s), and bamboo greenness of the greenness-reserved bamboo board(s) is reserved. The invention further discloses a processing technology of the greenness-reserved bamboo-wood composite board. The processing technology comprises the steps of selecting materials, conducting sawing-off, removing outer joints, removing inner joints, forming openings, conducting softening, conducting flattening, removing yellowness with the thickness fixed, conducting cooling for shaping, conducting drying at the low temperature, bonding the greenness-reserved bamboo board(s) with the refined wood board to form a greenness-reserved bamboo-wood composite board unit, conducting splicing, and bonding the greenness-reserved bamboo-wood composite board units to form the greenness-reserved bamboo-wood composite board. In the processing technological process, moso bamboo is softened, and no pollution is generated; in the drying process, the greenness-reserved bamboo boards are not deformed or cracked; and each bamboo greenness face maintains high hardness, flatness and smoothness.

Owner:浙江德长竹木有限公司

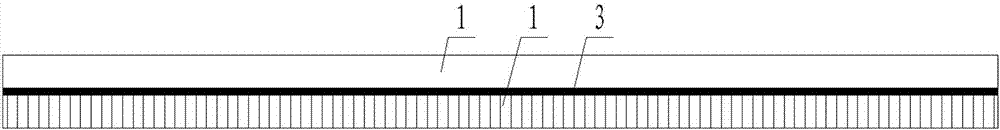

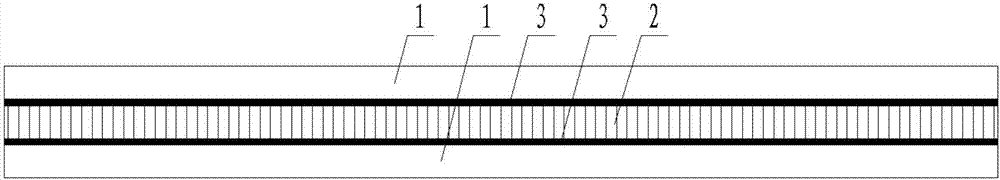

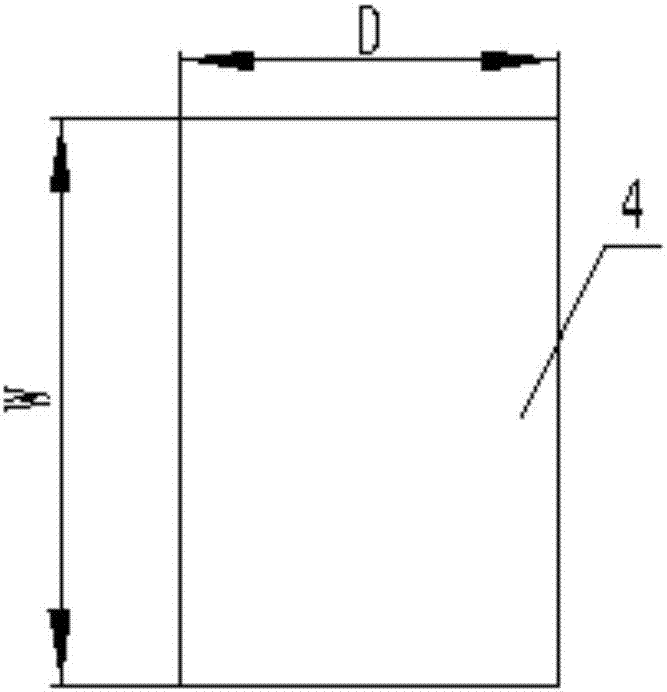

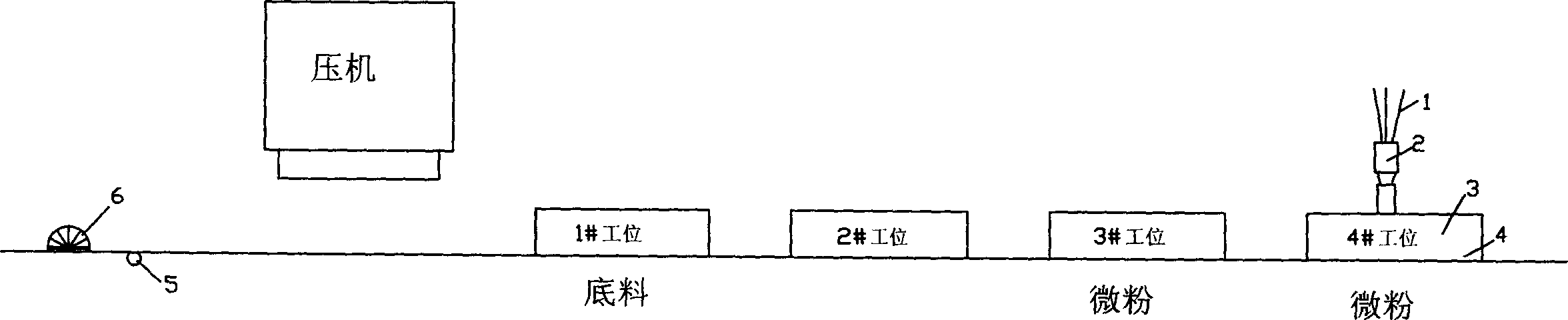

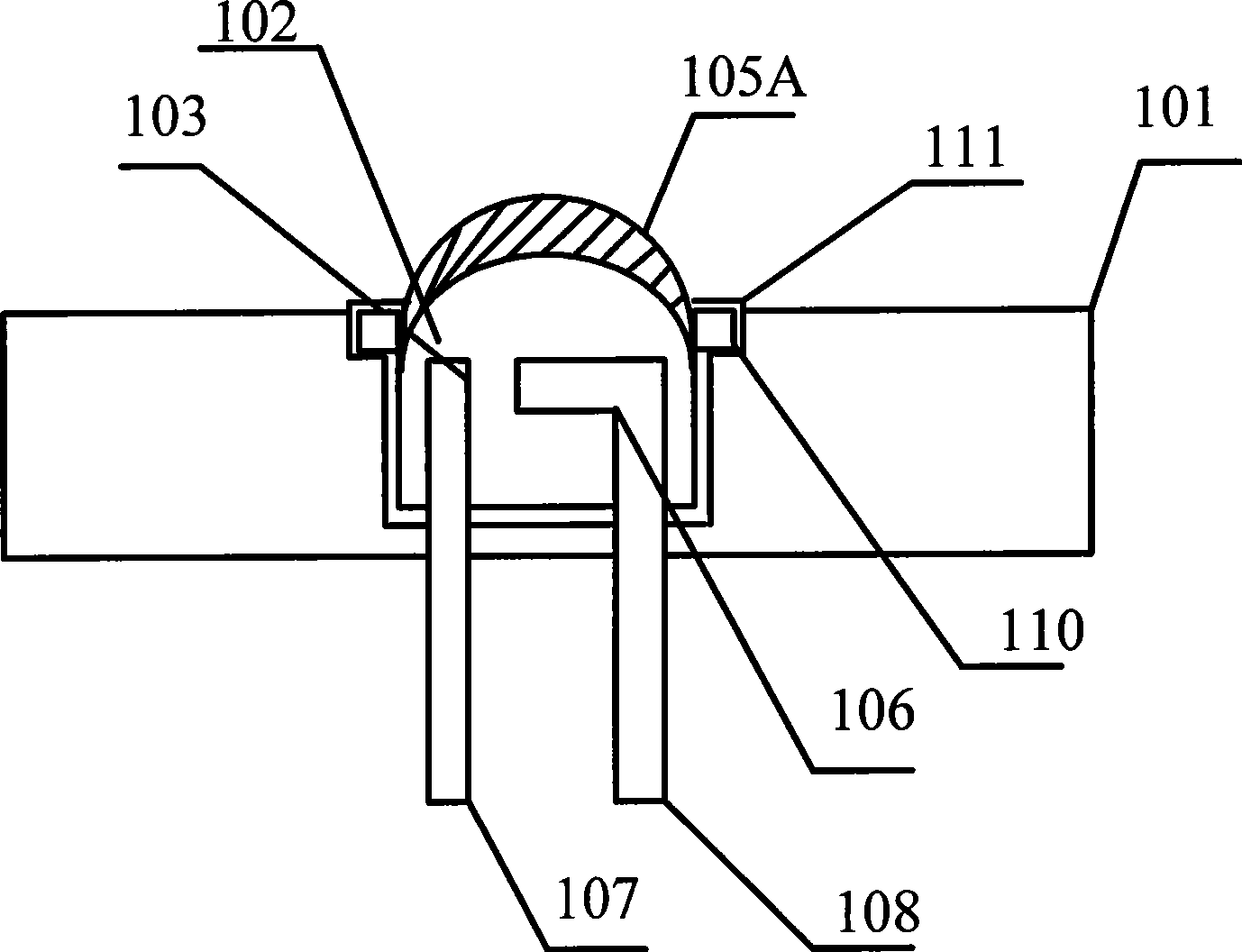

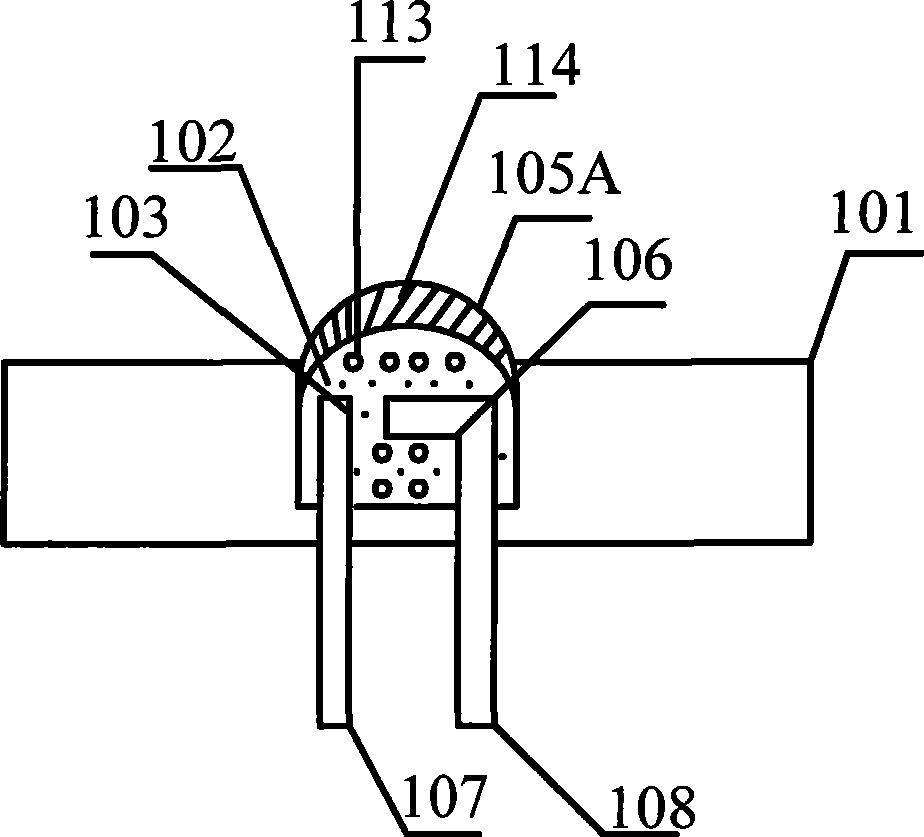

Ceramic brick surface material distribution method and equipment

ActiveCN1803725AAchieve decorative effectOvercoming repetitive flawsCeramic shaping apparatusScreen printingBrick

The invention discloses a surface distributing method and the opposite device for ceramic brick. Wherein, with multistation distributing technique, filling the micro powder into a concave convex pad by a template with special pattern to form pile; on successive station, printing the color powder on pile inclined surface by silk screen; adding micro powder to fill into the pile gap; then, on successive station, distributing the bottom material, removing to presser, and completing the operation. This invention is practical and has well effect.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Positioned-point piling type artificial fish reef releasing method and artificial fish reef obtained by method

InactiveCN103749363AOptical shadow complexEasy to inhabitClimate change adaptationPisciculture and aquariaRebarOcean current

The invention discloses a positioned-point piling type artificial fish reef releasing method. The method includes: using reinforced steel bars to connect 4-8 concrete components to form a single fish reef, going to the sea when the whether is good and ocean current is gentle in flow rate after multiple fish reefs are prepared, using a GPS for positioning, dropping the anchor of a ship at the positioned point, using a crane to release the fish reefs into the water on the leeward side and along the flowing direction of the ocean current, releasing 50-80 fish reefs at each positioning point to allow the fish reefs to form a rectangular fish reef pile whose length direction is vertical to the flowing direction of the ocean current, releasing multiple fish reef piles to allow the same to be distributed in a grid shape, wherein the distance between every two adjacent fish reef pile is 300-500m.

Owner:DALIAN OCEAN UNIV

Material distributing method and equipment of polished tiles

ActiveCN102248595BEasy to replaceNatural texture decorative effectCeramic shaping apparatusLamellar PatternEngineering

The invention discloses a material distributing method and equipment of polished tiles. The method is characterized by comprising the following steps of: a. preparing materials: respectively distributing line materials and plus materials into a line material feeding hopper and a plus material feeding hopper which are arranged in the moving direction of a main conveyor belt; b. after the line materials are sieved by a vibration sieve, distributing the sieved line materials on the main conveyor belt to form a banded thin-layered line material, and distributing the plus materials on the main conveyor belt by virtue of the intermittent opening and closing of the plus material feeding hopper to form a banded thick-layered plus material; c. enabling the banded thick-layered plus material to be formed into linear lamellar patterns with lines by virtue of the intermittent blocking action of a linear baffle, and warping the linear material layer into a wavy material layer by virtue of the intermittent blocking action of a wavy baffle; and d. transferring the effect of the wavy material layer into a press mould by virtue of a texture fidelity feeding grate. In the invention, natural and delicate texture effects with rich layers in imitation of natural stones are formed by virtue of the combination of the formula and process provided by the invention; the equipment is easy to modify, so the equipment can be flexibly suitable for design modification requirements of products; and the product conversion cycle is shortened, and the loss and production cost are reduced.

Owner:FOSHAN DONGPENG CERAMIC +2

Convex LED light bar, manufacturing method thereof and LED screen body

InactiveCN101545593AEasy to manufactureRich in changePoint-like light sourceElectric circuit arrangementsControl signalEngineering

The invention discloses a convex LED light bar, a manufacturing method thereof and an LED screen body. The LED light bar comprises at least one substrate, at least two grooves, at least two LEDs, at least one control chip and at least one group of connecting wires, wherein each LED comprises an LED tube core and a filler; the grooves are in a preset shape; the LED tube cores are arranged in the grooves; the fillers are positioned in the light-emitting directions of the LED tube cores, fixedly arranged above the grooves and arranged to be convex tube shells of the LEDs; the shape of the cross section of each convex tube shell is arranged to be that of the cross section of each groove; and the control chip is used for receiving control signals and sending the control signals to the LEDs. Thus the LEDs can be smaller and easier to manufacture, so that the smaller LED light bar and the lighter thinner LED screen can be manufactured.

Owner:BEIJING ZHONGQING MICRO ELECTRIC TECH

Walking Toy and Walking Toy Set

InactiveUS20150217202A1Less liable to fall down during walkingEasilySelf-moving toy figuresToy gearsGear wheelCoil spring

A walking toy includes a body on which gravity center position adjusting members and paired legs are supported to be able to swing in a forward / backward direction, and a gearbox which has a crank mechanism for forcibly swinging the paired legs alternately forward and backward in a forcible swinging direction and which is mounted in the body. Each of the paired legs has a bottom which is configured to be in contact with a floor surface and which is formed into a curved face curved in the forcible swinging direction. The gearbox is driven by a torsion coil spring and has a lever which rotates a drive gear of a gear train for transmitting rotation of the torsion coil spring to an output shaft for rotating the crank mechanism.

Owner:MDWORKS

Double-color jacquard three-layer base cloth fabric and weaving method thereof

InactiveCN105734765AQuality improvementSolidifiedMulti-ply fabricsSwivel-woven fabricsBobbinEngineering

The invention discloses a double-color jacquard three-layer base cloth fabric. The double-color jacquard three-layer base cloth fabric consists of an upper base cloth layer, a middle base cloth layer, a lower base cloth layer, and nap warps, wherein the nap warps are weaved among the upper base cloth layer, the middle base cloth layer and the lower base cloth layer in a reciprocating way; the nap warps consist of nap warps of two colors, and the nap warps of two colors are performed with conversion and jacquard weaving between the upper base cloth layer and the middle base cloth layer as well as between the lower base cloth layer and the middle base cloth layer; nap tissues of the same pattern and different colors are formed on the two surfaces of the middle base cloth layer, the lower surface of the upper base cloth layer and the upper surface of the lower base cloth layer; after secondary nap cutting, the upper layer is a single-surface nap fabric, the middle layer is a double-surface nap fabric, and the lower layer is a single-surface nap fabric. The double-color jacquard three-layer base cloth fabric has the advantages that a bobbin creel and the warp drawing are not needed, and the double-color jacquard three-layer base cloth fabric with two single-surface double-color jacquard nap pieces and one double-surface double-color jacquard nap piece can be directly obtained through primary weaving and secondary nap cutting. The invention also discloses a weaving method of the double-color jacquard three-layer base cloth fabric.

Owner:LIAONING CAIYI WILD SILK PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com