Ceramic brick surface material distribution method and equipment

A ceramic tile and cloth technology, applied in the field of ceramic tile cloth, can solve the problems of unpredictability and advance control of patterns, unstable mass production of products, and difficulties in production technology control, etc., and achieve low product unit cost, stable product patterns and colors , Color patterns rich in changing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

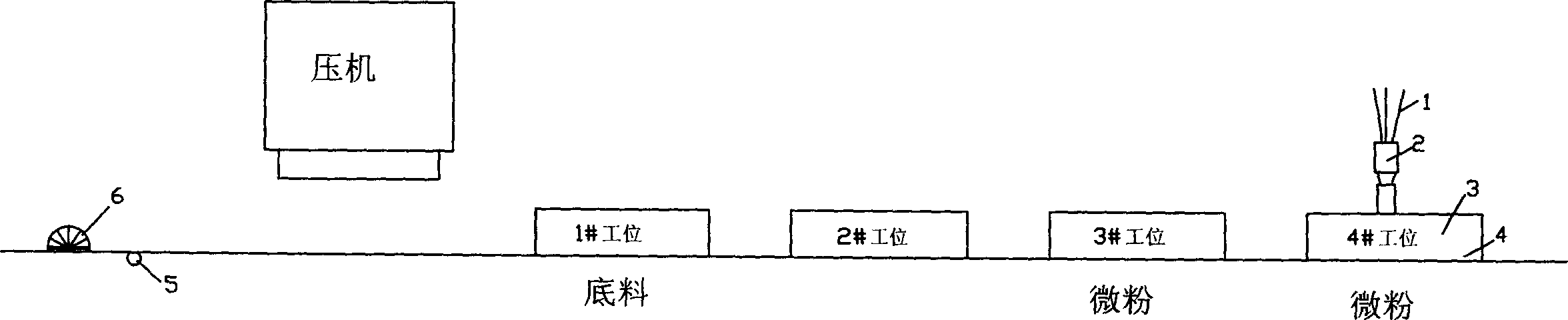

[0019] Such as figure 1 As shown, the equipment of the present invention includes a transmission device, a multi-distributing station arranged on the transmission device, a material pipe 1 and a micropowder mixing bucket 2 arranged on the upper part of the station, and a concave-convex skin is arranged on the cloth station of the transmission device. Pad 4, a template 3 is also set above the concave-convex leather pad 4. The production process using the surface cloth method and equipment of the present invention is:

[0020] (1) Using the existing multi-station fabric technology in the market, the concave-convex leather pad 4 is moved to the 4# station through the transmission device, and the micropowder is filled into the concave-convex leather pad 4 through the hollowed-out template 3 with a certain pattern, so that it is formed Block-shaped stockpile, then line toner is printed on the slope of the stockpile by screen printing at the follow-up station, and the concave-conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com