In-mold decoration (IMD) production technology for switch panel

A switch panel and production process technology, which is applied in the field of IMD production process of the switch panel, can solve the problems of insufficient three-dimensional and bright decorative surface colors, complicated production procedures, easy fading of the surface, etc., saving assembly processes, good moisture resistance, and reducing The effect of development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

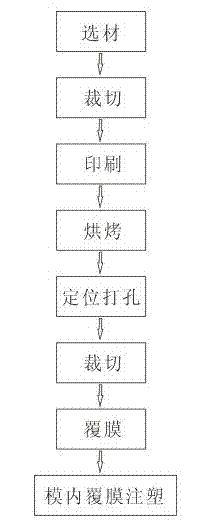

[0038] Such as figure 1 Shown, a kind of IMD production process of switch panel, the making of described switch panel adopts IMD process, and its steps are as follows:

[0039] 1. Material selection: prepare 0.125MM polyester sheet, polyester refers to polyethylene terephthalate, referred to as PET;

[0040] 2. Cutting: Cut the PET sheet into a size of 90CM×90CM, and the size is determined according to the needs of the printing machine;

[0041] 3. Printing: Offset printing on the PET sheet;

[0042] 3-1. PET sheet printing needs to be ranked by AI graphics, and after the size is confirmed, the printing screen is made;

[0043] 3-2. After the screen plate is made, pattern printing is carried out;

[0044] 3-3. Make the background color of PET sheet: make it with a semi-automatic printing machine, first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com