Preparation method of corrosion-resistance and high-electroconductibility composite coating for electrode

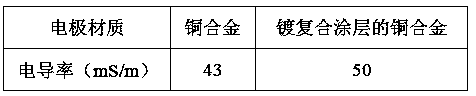

A composite coating and conductivity technology is applied in the field of preparation of composite coatings for electrodes, which can solve the problems of demanding high-temperature furnace performance and vacuum degree, difficult to prepare composite electrode materials with titanium oxide film wrapping layer, complicated processes, etc. Achieve the effects of good solvent resistance, improved current density, and enhanced film adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a composite coating for an electrode with corrosion resistance and strong conductivity. The electrode is a Cu alloy electrode. The composite coating includes a Ti film and a titanium oxide coating film sequentially plated on the surface of the Cu alloy electrode, replacing part of the whole The sintered titanium peroxide electrode, due to the extremely thin thickness of the composite coating, greatly reduces the amount of titanium peroxide used; the specific steps are as follows:

[0020] (1) Take the Cu alloy electrode, put it into a mixture of acetone and alcohol, ultrasonically clean it for 10 minutes, and perform deoxidation and impurity removal. Since the organic matter is decomposed into O 2 、H 2 Small molecules such as O and CO are easy to introduce oxygen, and the ultrasonic method can remove oil and impurities from the Cu electrode substrate and prevent the decomposition of organic matter;

[0021] (2) Weigh titanium suboxide powder and ...

Embodiment 2

[0025] A method for preparing a composite coating for an electrode with corrosion resistance and strong conductivity. The electrode is a Cu alloy electrode. The composite coating includes a Ti film and a titanium oxide coating film sequentially plated on the surface of the Cu alloy electrode, replacing part of the whole The sintered titanium peroxide electrode, due to the extremely thin thickness of the composite coating, is 3 μm, which greatly reduces the amount of titanium peroxide used; the specific steps are as follows:

[0026] (1) Take the Cu alloy electrode, put it into a mixture of acetone and alcohol, ultrasonically clean it for 8 minutes, and perform deoxidation and impurity removal. Since the organic matter is decomposed into O 2 、H 2 Small molecules such as O and CO are easy to introduce oxygen, and the ultrasonic method can remove oil and impurities from the Cu electrode substrate and prevent the decomposition of organic matter;

[0027] (2) Weigh titanium suboxi...

Embodiment 3

[0031] A method for preparing a composite coating for an electrode with corrosion resistance and strong conductivity. The electrode is a Cu alloy electrode. The composite coating includes a Ti film and a titanium oxide coating film sequentially plated on the surface of the Cu alloy electrode, replacing part of the whole The sintered titanium peroxide electrode, due to the extremely thin thickness of the composite coating, is 2 μm, which greatly reduces the amount of titanium peroxide used; the specific steps are as follows:

[0032] (1) Take the Cu alloy electrode, put it into a mixture of acetone and alcohol, ultrasonically clean it for 8 minutes, and perform deoxidation and impurity removal. Since the organic matter is decomposed into O 2 、H 2 Small molecules such as O and CO are easy to introduce oxygen, and the ultrasonic method can remove oil and impurities from the Cu electrode substrate and prevent the decomposition of organic matter;

[0033] (2) Weigh titanium suboxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com