Microorganism loading type resin adsorbent capable of degrading greasy dirt and preparation method of resin adsorbent

A technology of resin adsorption and microorganisms, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as inconvenience, achieve the effect of increasing service life, strong adsorption capacity, and ensuring long-term survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

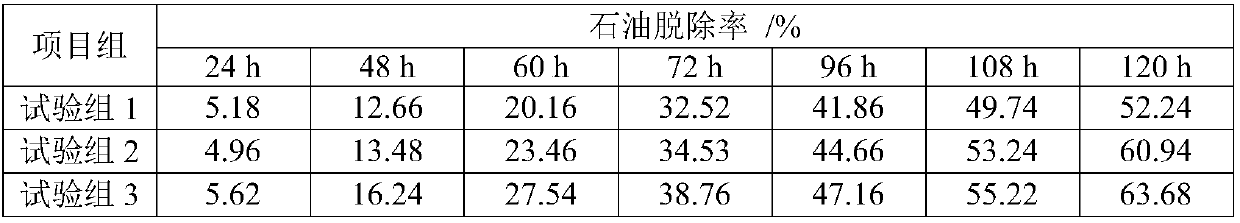

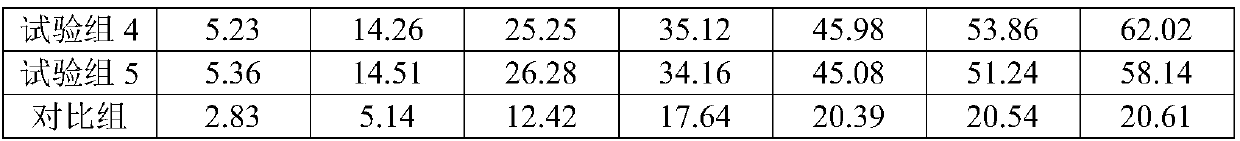

Embodiment 1

[0032] A preparation method of a microbial-loaded resin adsorbent capable of degrading oil stains, comprising the following steps:

[0033] (1) The konjac glucomannan airgel particle of 10g is added in the seed bacterium liquid of the brevibacillus of 20g, and the strain concentration of brevis bacillus is 6 * 10 9 cell / g, until konjac glucomannan airgel adsorption seed bacterial liquid is saturated to obtain konjac glucomannan airgel liquid;

[0034] (2) The above-mentioned konjac glucomannan airgel liquid is mixed with 1000 g of sodium alginate solution with a mass concentration of 4wt%, and then injected into a calcium chloride solution with a mass concentration of 2.5wt%, and cross-linked to obtain a microbial load ;

[0035] (3) Add 65g of methacrylate monomer, 20g of styrene, 0.5g of initiator, and 3g of emulsifier into 250g of water and stir and emulsify for 1 hour to obtain an emulsion. Add 3g of crosslinking agent and porogen to the emulsion After 45 g of nitrogen g...

Embodiment 2

[0039] A preparation method of a microbial-loaded resin adsorbent capable of degrading oil stains, comprising the following steps:

[0040] (1) The konjac glucomannan airgel particles of 10g are added in the seed bacterium liquid of 27.5g brevibacillus, and the strain concentration of brevis bacillus is 6 * 10 9 cell / g, until konjac glucomannan airgel adsorption seed bacterial liquid is saturated to obtain konjac glucomannan airgel liquid;

[0041] (2) The above-mentioned konjac glucomannan airgel liquid is mixed with 1000 g of sodium alginate solution with a mass concentration of 5 wt%, and then injected into a calcium chloride solution with a mass concentration of 2.75 wt%, and cross-linked to obtain a microbial load ;

[0042] (3) Add 70g of methacrylate monomer, 22.5g of styrene, 0.75g of initiator, and 4g of emulsifier into 300g of water and stir and emulsify for 1.5h to obtain an emulsion. Add 3.5g of crosslinking agent, After 47.5 g of the porogen, pass nitrogen gas a...

Embodiment 3

[0046] A preparation method of a microbial-loaded resin adsorbent capable of degrading oil stains, comprising the following steps:

[0047] (1) The konjac glucomannan airgel particle of 10g is added in the seed bacterium liquid of the brevibacillus of 35g, and the strain concentration of brevis bacillus is 6 * 10 9 cell / g, until konjac glucomannan airgel adsorption seed bacterial liquid is saturated to obtain konjac glucomannan airgel liquid;

[0048] (2) Mix the above-mentioned konjac glucomannan airgel liquid with 1000 g of a sodium alginate solution with a mass concentration of 6 wt%, and then inject it into a calcium chloride solution with a mass concentration of 3 wt%, and cross-link to obtain a microbial load;

[0049] (3) Add 75g of methacrylate monomer, 25g of styrene, 1g of initiator, and 5g of emulsifier into 350g of water and stir and emulsify for 1.5h to obtain an emulsion. Add 4g of crosslinking agent and porogen to the emulsion After 50 g, pass nitrogen gas and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com