Material distributing method and equipment of polished tiles

A technology of polishing tiles and fabrics, which is applied in the field of polishing tile production, can solve problems such as difficult modification, failure to form, cumbersome control, etc., and achieve the effect of easy replacement and easy production change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

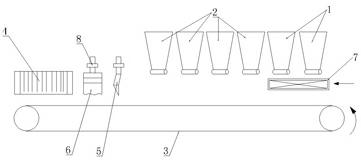

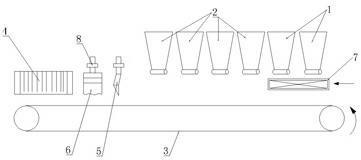

[0018] A kind of polishing brick distributing method of the present invention, it comprises the following steps:

[0019] a. Ingredients, and put the thread material and fabric into the thread material lower hopper and fabric lower hopper set along the moving direction of the conveyor belt respectively; among them, the thread material can be dark-colored material or milky white material, and the fabric can be transparent material Or light-colored fabrics to make the layered effect more three-dimensional.

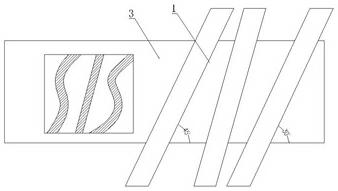

[0020] b. Open the thread material lowering hopper, let the thread material fall into the vibrating screen and sieve, and then distribute it into the main conveyor belt, and form a strip-shaped thin layer of thread material; the fabric lower hopper is intermittently opened and closed to form the fabric cloth on the main conveyor belt Ribbon thick fabric;

[0021] c. The intermittent blocking action of the strip-shaped thick-layer fabric through the linear baffle makes it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com