Spinning machine and false twist unit

A textile machine and false twisting technology, applied in the direction of textiles and papermaking, to achieve the effect of reducing tension difference and reducing tension difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

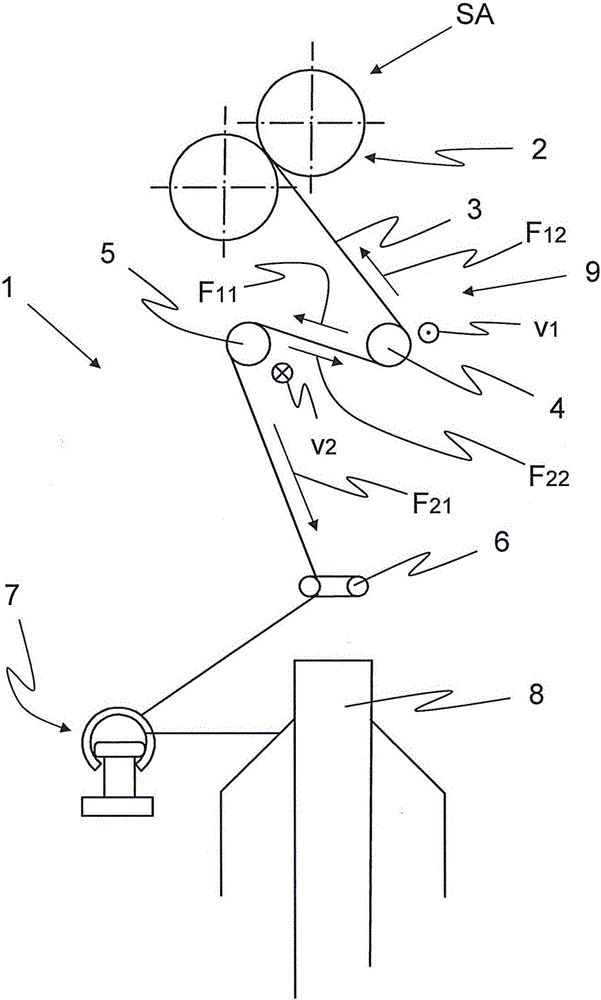

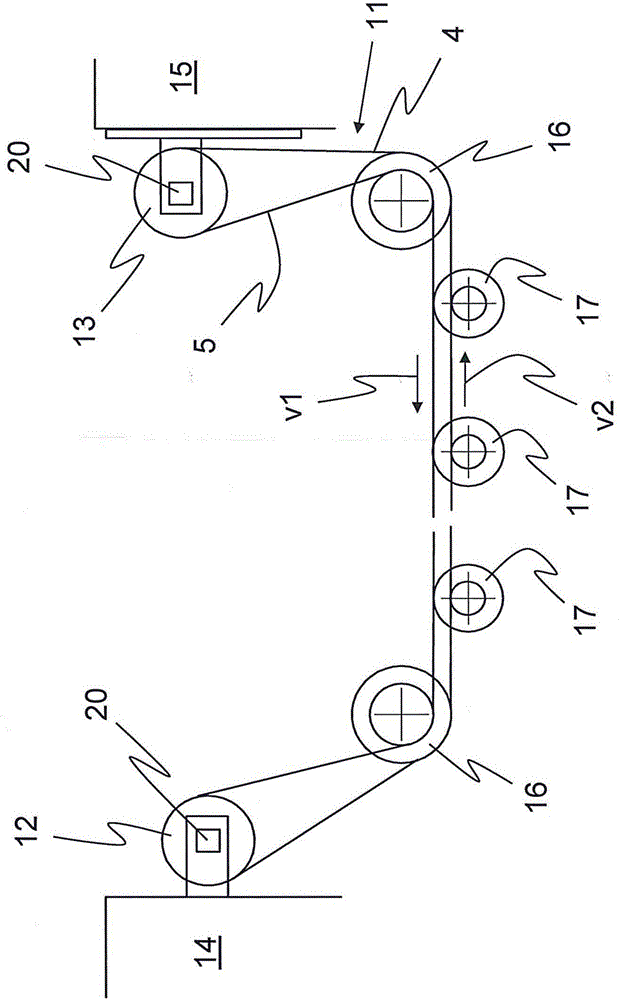

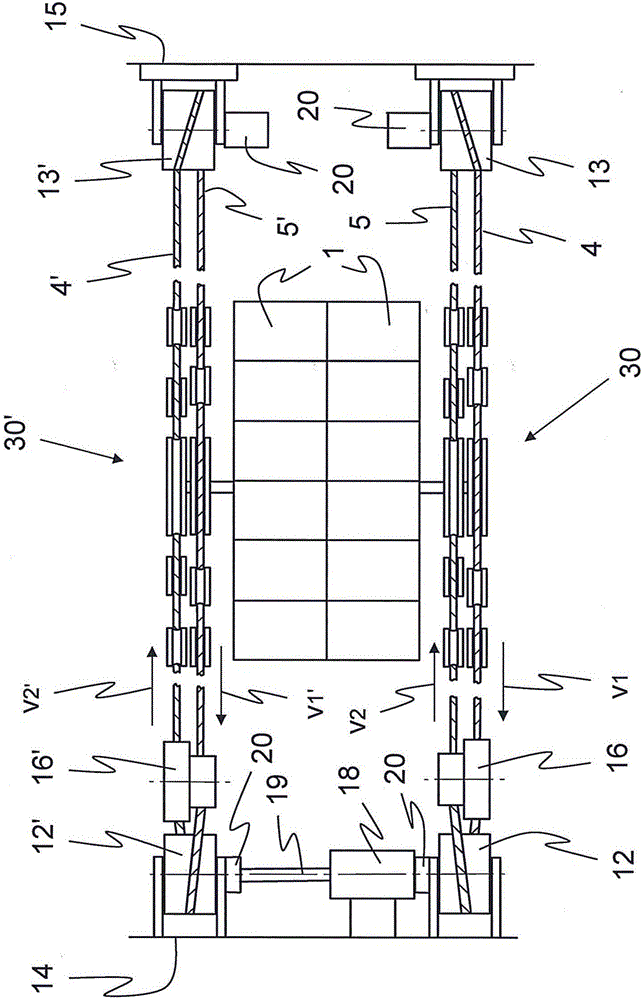

[0080] exist figure 1 The weaving unit 1 of the weaving machine 10 is schematically and partially shown in FIG. The delivery roll pair 2 of the drafting unit, not shown, supplies the ply strand 3 and forms the drafting unit output SA. The strand 3 turns around a first plastic belt 4 and then around a second plastic belt 5 . Subsequently, the ply thread 3 passes through the twist stopper 6 and the traveler 7, and is wound on the bobbin 8 at last. The first plastic belt 4 and the second plastic belt 5 form a false twist device 9 . The two plastic belts 4 and 5 can refer to two separate belts 4 and 5 or to stretching and pushing return sections of a single belt.

[0081] The first plastic belt 4 and the second plastic belt 5 or both runs have opposite directions of movement. Since the ply thread 3 lies on two belts 4 and 5 moving in opposite directions, the yarn is stretched in one direction by one return and in the other direction by the other return. The ply wire 3 is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com