Special continuous casting crystallizer function protecting material for sulfur free-cutting steel and preparation method thereof

A technology for continuous casting crystallizers and protective materials, which is applied in the field of functional protective materials for continuous casting molds for sulfur-based free-cutting steels and its preparation. The effect of reducing the risk of sticking due to the large tendency of chemical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

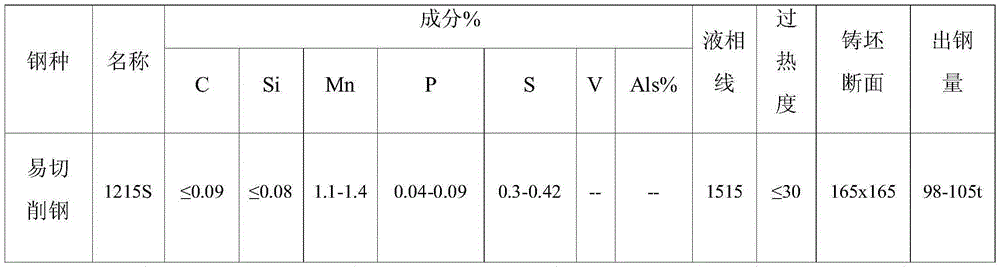

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A special continuous casting mold functional protection material for sulfur-based free-cutting steel, the chemical composition and weight percentage of the protection material are: SiO 2 40%, CaO27.2%, Li 2 O2.0%, Al 2 o 3 12.2%, K 2 O+Na 2 O5.5%, F - 6.3%, MgO5.0%, Fe 2 o 3 1.8%.

[0041] The protective material is made of the following raw materials in terms of weight percentage: 68.0% premelt, 3.0% lithium carbonate, 6.0% high fluorite powder, 1.5% high alumina, 2.0% cryolite, 1.0% sodium fluoride, Fine glass powder 1.0%, sodium carbonate 5.5%, imported carbon black 5.0% and graphite 7.0%.

[0042] The composition and weight percentage of the premelt are: SiO 2 47.0%, CaO40.0%, Al 2 o 3 5.0%, Li 2 O+K 2 O+Na 2 O6.0%, F - 4.0%. It is obtained by grinding waste glass slag, quartz ore, coke powder, low-grade fluorite, and soda through coarse grinding, stirring, high-temperature calcination, water quenching, drying, grinding and crushing to 300 meshes, an...

Embodiment 2

[0045] A special continuous casting mold functional protection material for sulfur-based free-cutting steel, the chemical composition and weight percentage of the protection material are: SiO 2 39.5%, CaO23.7%, Li 2 O2.5%, Al 2 o 3 16.0%, K 2 O+Na 2 O6.5%, F - 6.3%, MgO4.0%, Fe 2 o 3 1.5%,.

[0046] The protective material is made of the following raw materials in terms of weight percentage: 58.0% premelt, 5.0% lithium carbonate, 6% high fluorite powder, 3.5% high alumina, 5.5% cryolite, 2.5% sodium fluoride, Fine glass powder 2.5%, sodium carbonate 7.0%, imported carbon black 4.0% and graphite 4.0%.

[0047] The composition and weight percentage of the premelt are: SiO 2 45.0%, CaO35.0%, Al 2 o 3 7.0%, Li 2 O+K 2 O+Na 2 O7.0%, F - 10.0%. It is obtained by grinding waste glass slag, quartz ore, coke powder, low-grade fluorite, and soda through coarse grinding, stirring, high-temperature calcination, water quenching, drying, grinding and crushing to 400 meshes, ...

Embodiment 3

[0050] A special continuous casting crystallizer functional protection material for sulfur-based free-cutting steel, the chemical composition and weight percentage of the protection material are: CaO27.0%, Li 2 O3.5%, Al 2 o 3 18.3%, K 2 O+Na 2 O8.5%, F - 7.0%, MgO4.2%, Fe 2 o 3 1.5%, SiO 2 30.0%,.

[0051] The protective material is made of the following raw materials in terms of weight percentage: 59.5% premelt, 4.5% lithium carbonate, 8% high fluorite powder, 3.5% high alumina, 3.5% cryolite, 3.0% sodium fluoride, Fine glass powder 2.5%, sodium carbonate 6.5%, imported carbon black 3.5% and graphite 5.5%.

[0052] The composition and weight percentage of the premelt are: SiO 2 47.0%, CaO33.0%, Al 2 o 3 3%, Li 2 O+K 2 O+Na 2 O16.0%, F - 1.0%. It is obtained by grinding waste glass slag, quartz ore, coke powder, low-grade fluorite, and soda through coarse grinding, stirring, high-temperature calcination, water quenching, drying, grinding and crushing to 400 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com