High-reliability fuel metering device driven by stepping motor

A technology of stepping motors and metering devices, which is applied to mass flow measurement devices, indirect mass flow meters, etc., and can solve problems such as wear, difficulty in ensuring system stability, and low robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical solutions, implementation methods and advantages of the present invention more clear and detailed, the present invention will be further described in detail below in conjunction with the attached schematic diagrams and specific examples.

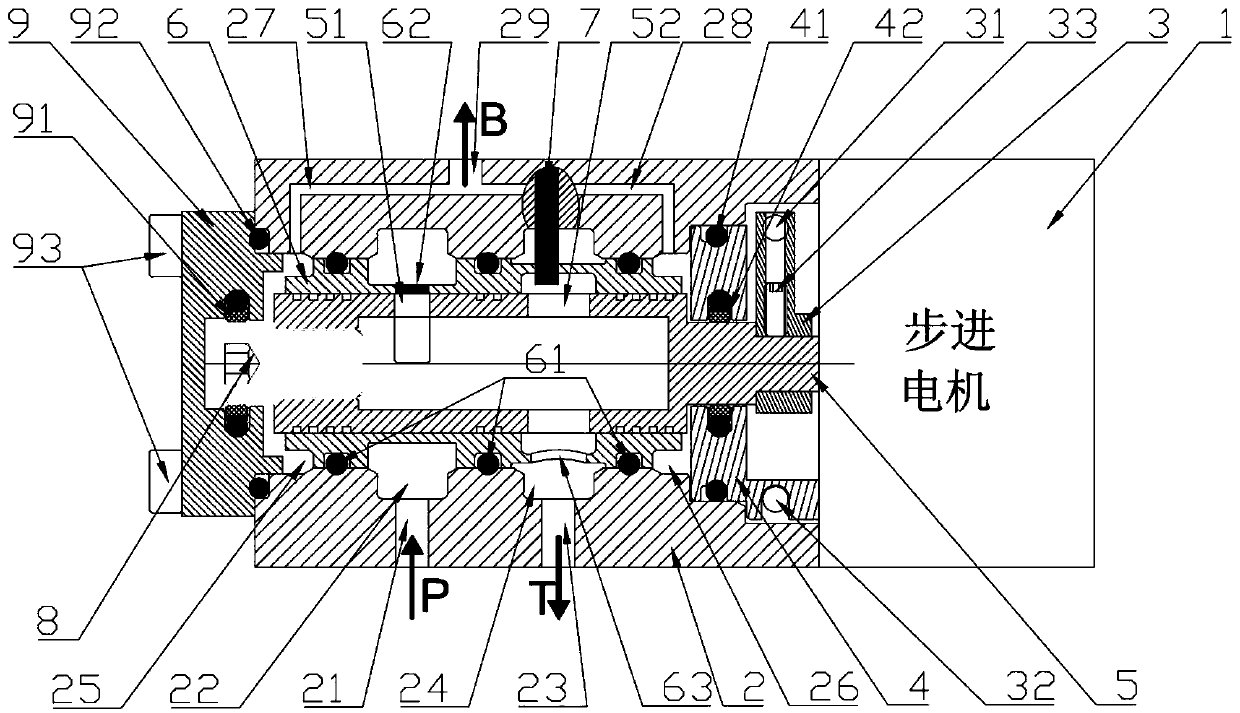

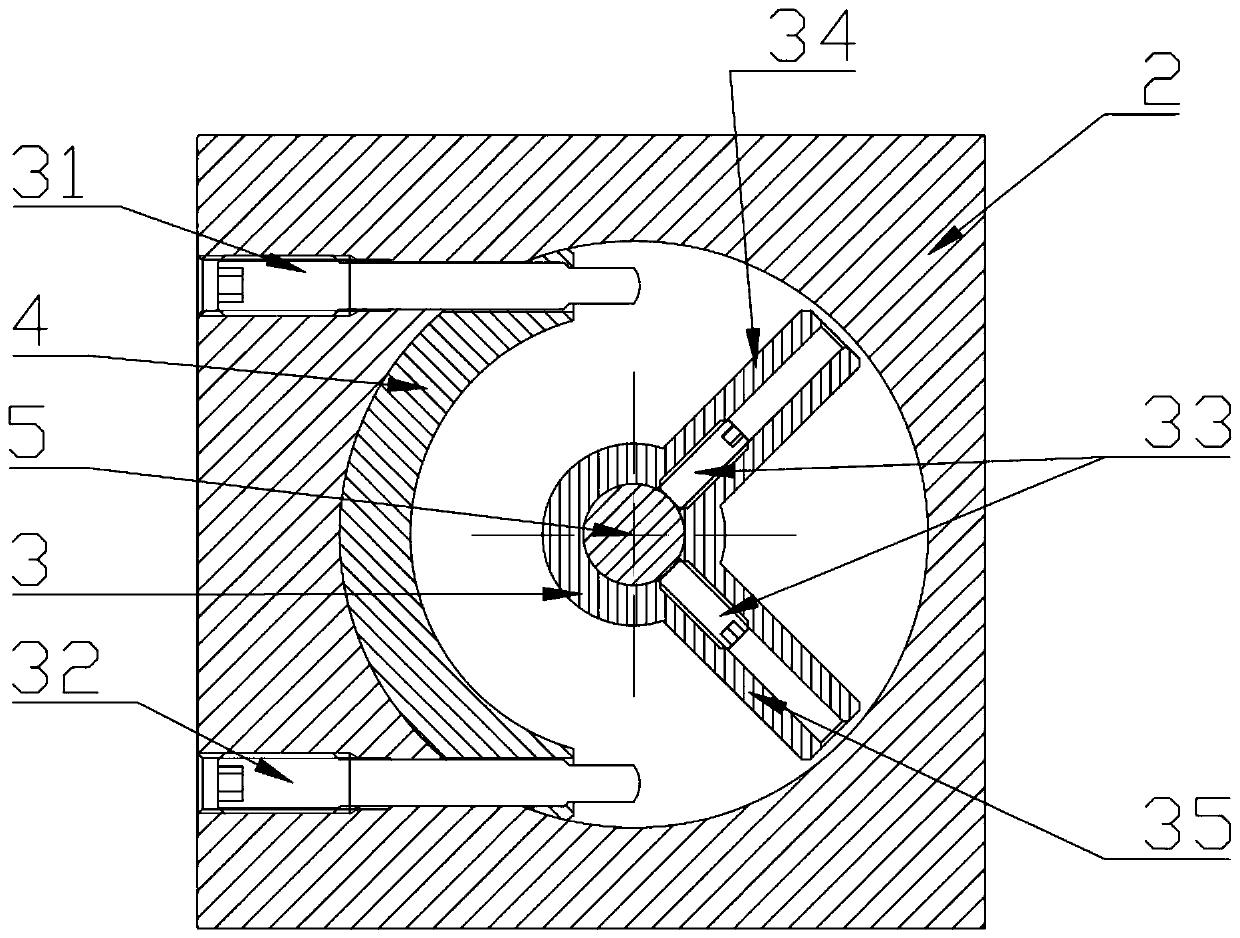

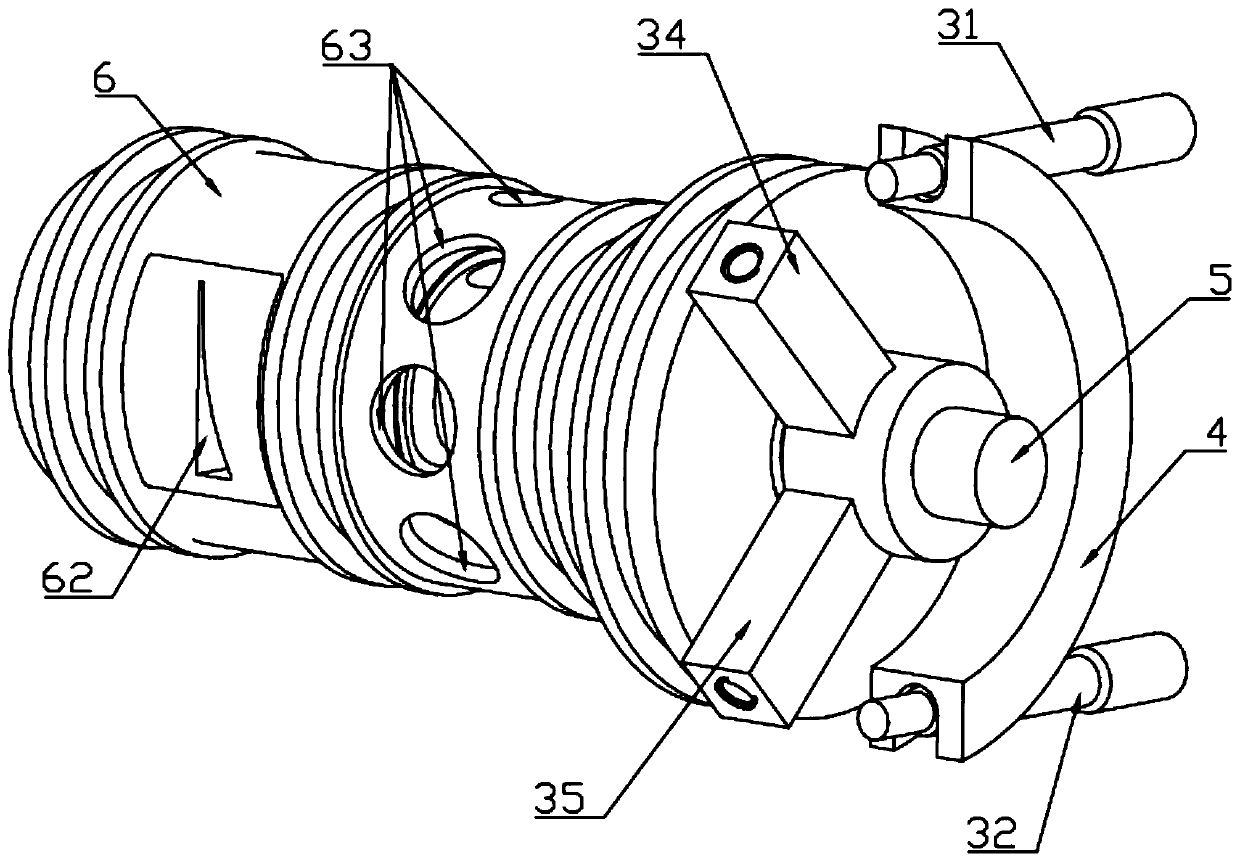

[0052] figure 1 It is a front view cross-sectional schematic diagram of a highly reliable fuel metering device driven by a stepping motor proposed by the present invention, and its composition includes a stepping motor 1 and a metering valve assembly. The metering valve assembly includes a metering valve housing 2, a metering valve limiter 3, a metering valve spool 5, a metering valve sleeve 6, a metering valve movable sealing cover 4, and a metering valve rear end cover 9. The metering valve housing 2 is a hollow cylindrical part with openings at both ends. The metering valve valve core 5 and the metering valve sleeve 6 are arranged in the metering valve housing 2. At least On a stepped surface, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com