Multi-piece piston for a cold chamber casting machine

A multi-piece, casting machine technology, applied in the field of multi-piece pistons, can solve the problems of impossibility to eliminate sticking and sticking, easy to wear, etc., and achieve the effect of simplifying structure and manufacturing, and facilitating cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

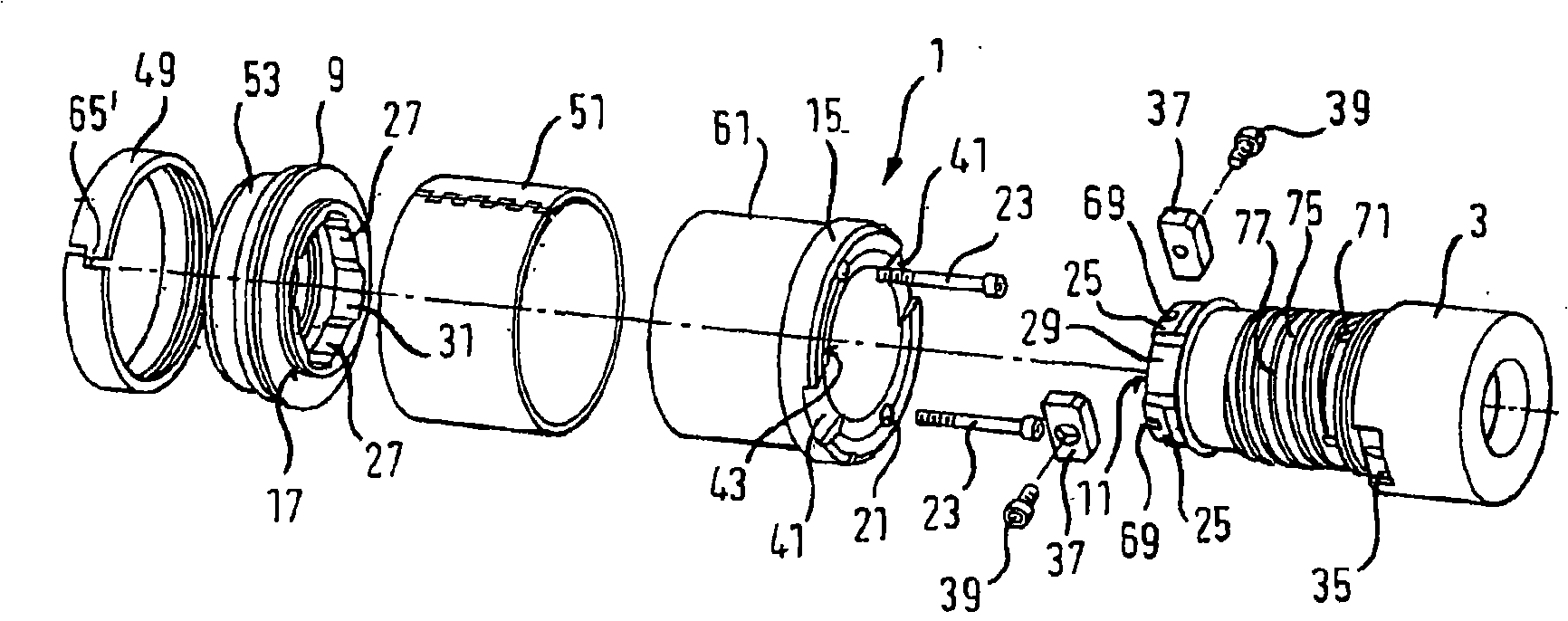

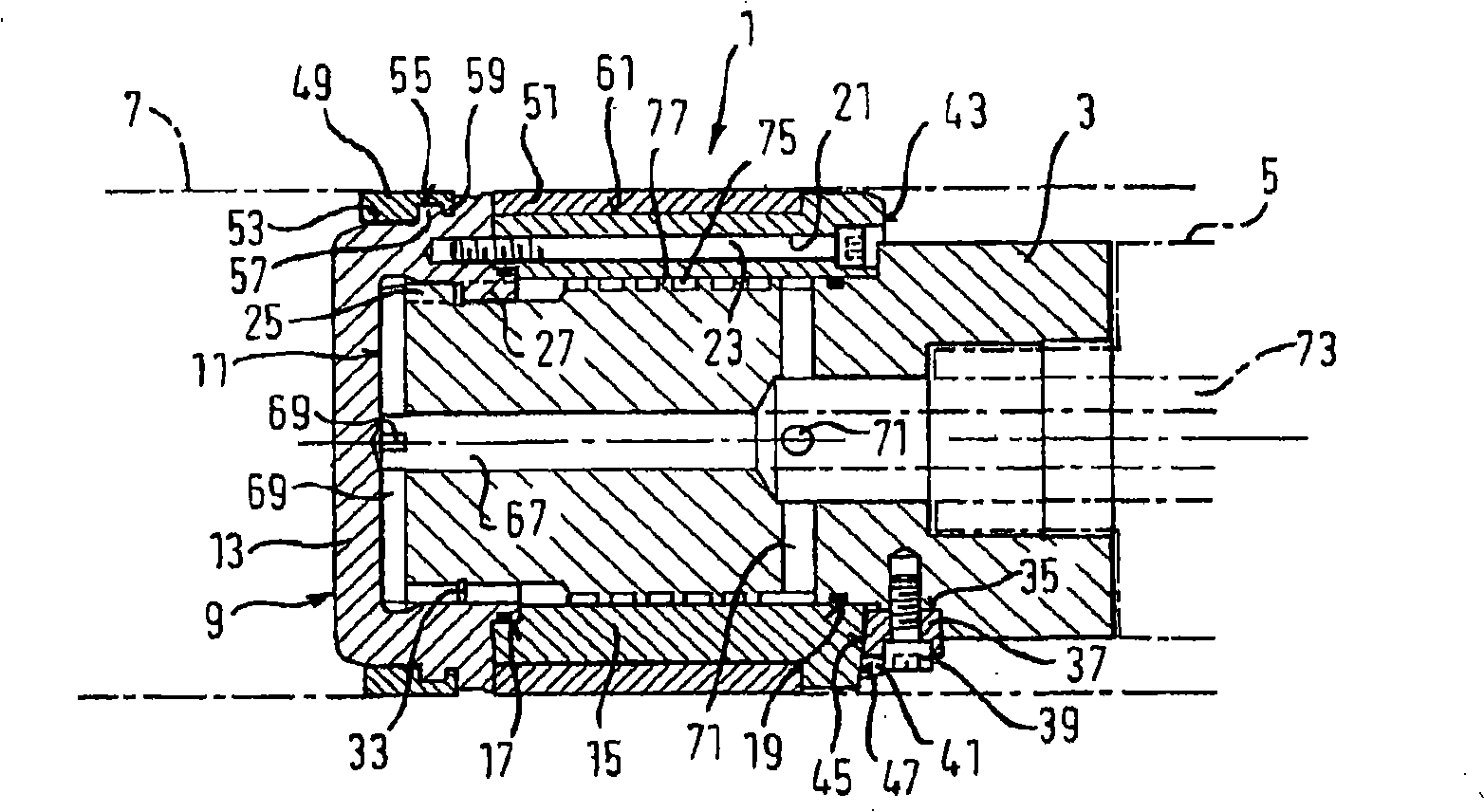

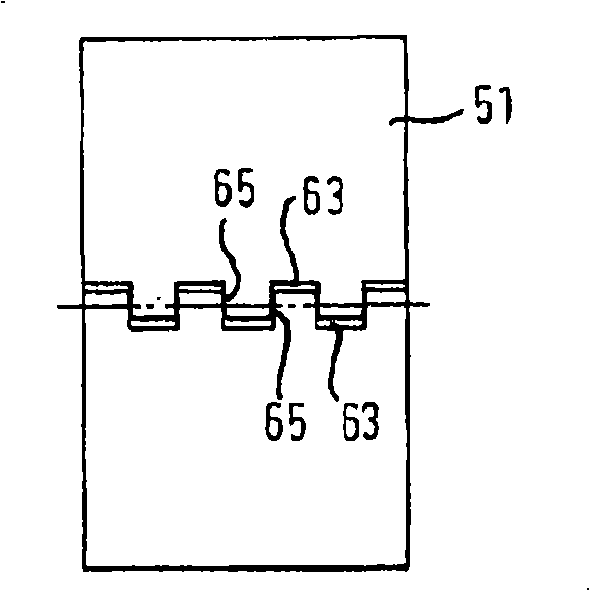

[0042] figure 1 and 2 A cap-shaped piston 1 cooled in a manner to be explained in more detail below is shown for a cold-chamber casting machine for metals, for example aluminum alloys. Piston 1 includes a piston carrier 3 which itself forms the end region of a piston rod indicated at 5 and is screwed, for example, to the piston rod. The piston 1 is moved in a manner known per se in the casting cylinder indicated by 7 of the cold chamber casting machine, driven by means of the piston rod 5 .

[0043] Piston 1 is multi-part and includes a piston cover 9 which, on the high-pressure side of piston 1 , forms a piston end wall 13 which rests in one face on an axis-perpendicular end face 11 of piston carrier 3 . Towards the low-pressure side, a piston body 15 in the form of a sleeve adjoins the piston cover 9 on the overlapping end face 11 . It is radially centered on the high-pressure side on an annular shoulder 17 of the piston cover 9 and on the low-pressure side on an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com