Mud splash-proof valve for oil drilling

An oil drilling and mud technology, which is applied in the field of mud splash valve for oil drilling, can solve the problems of increasing safety hazards, low reliability, affecting operations, etc., to simplify processing and installation processes, increase system performance stability, and increase sealing The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

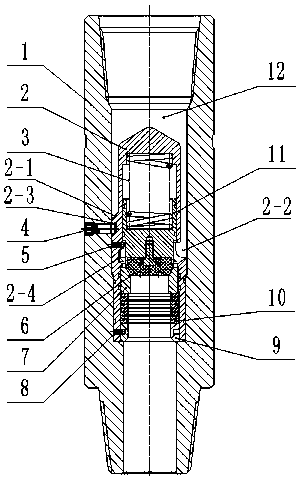

[0017] The mud splash prevention valve for oil drilling includes a shell 1, a valve core body 2, a spring 3, a valve seat 7, a strong spring 10, a piston 11, a "Jie"-shaped vertical rib 2-1, and a "Twenty"-shaped flow channel 2-2 , fixed groove 2-3, "boat" shaped deceleration groove 2-4, fixed screw 4, limit pin 5, valve core 6, support pin 8, support seat 9, mud channel 12, except shell 1, fixed screw 4 The other accessories outside form the integral valve core, in which the shell 1 is in the shape of a round tube, the integral valve core is supported on the second step of the inner hole, and the valve core body 2 is in the shape of a barrel with an open lower end. There are two annular grooves on the upward barrel wall of the first step. There are seals in the grooves, and the valve seat 7 is installed in close fit. The spring 3 is supported by the bottom of the barrel. Rib 2-1 and three "Twenty" shaped runners 2-2 connected with the inside of the barrel, three 120° evenly d...

Embodiment 2

[0024] What is different from the above example is that the strong spring 10 is a group of cylindrical helical composite springs with rectangular cross section.

[0025] The spool 6 has an integral structure and is processed by polyether ether ketone.

[0026] The material of the valve seat 7 is ceramics.

Embodiment 3

[0028] The difference from the above two examples is that the valve core 6 is a monolithic structure, which is processed from a composite material composed of polytetrafluoroethylene, molybdenum disulfide, copper powder and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com