Furnace beam and vertical column fire-resistant thermal insulation lining structure of walking beam furnace for heating high-temperature oriented silicon steel and manufacturing method of structure

A walking heating furnace and oriented silicon steel technology, which is applied in the field of heating furnaces, can solve the problems of lower surface temperature, higher maintenance costs, and damage to the integrity of heat insulation linings, so as to buffer the difference in thermal expansion performance, improve high temperature oxidation resistance, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

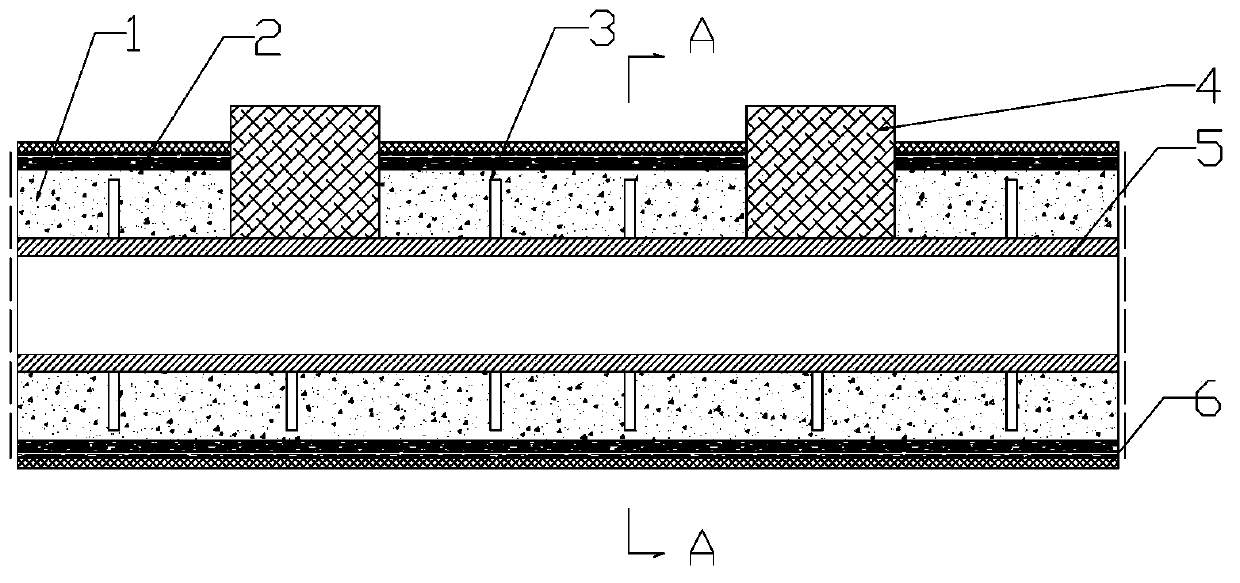

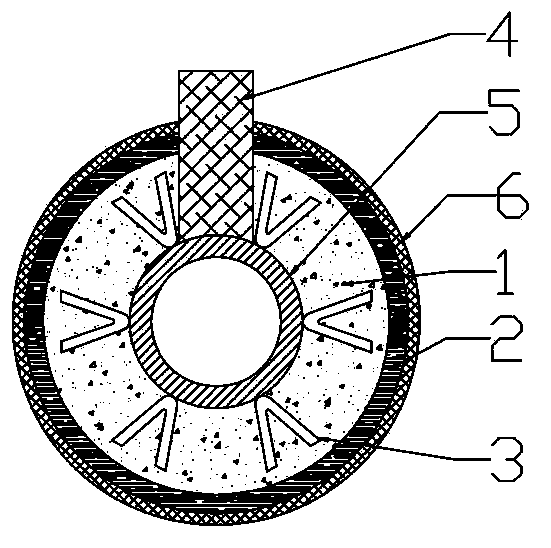

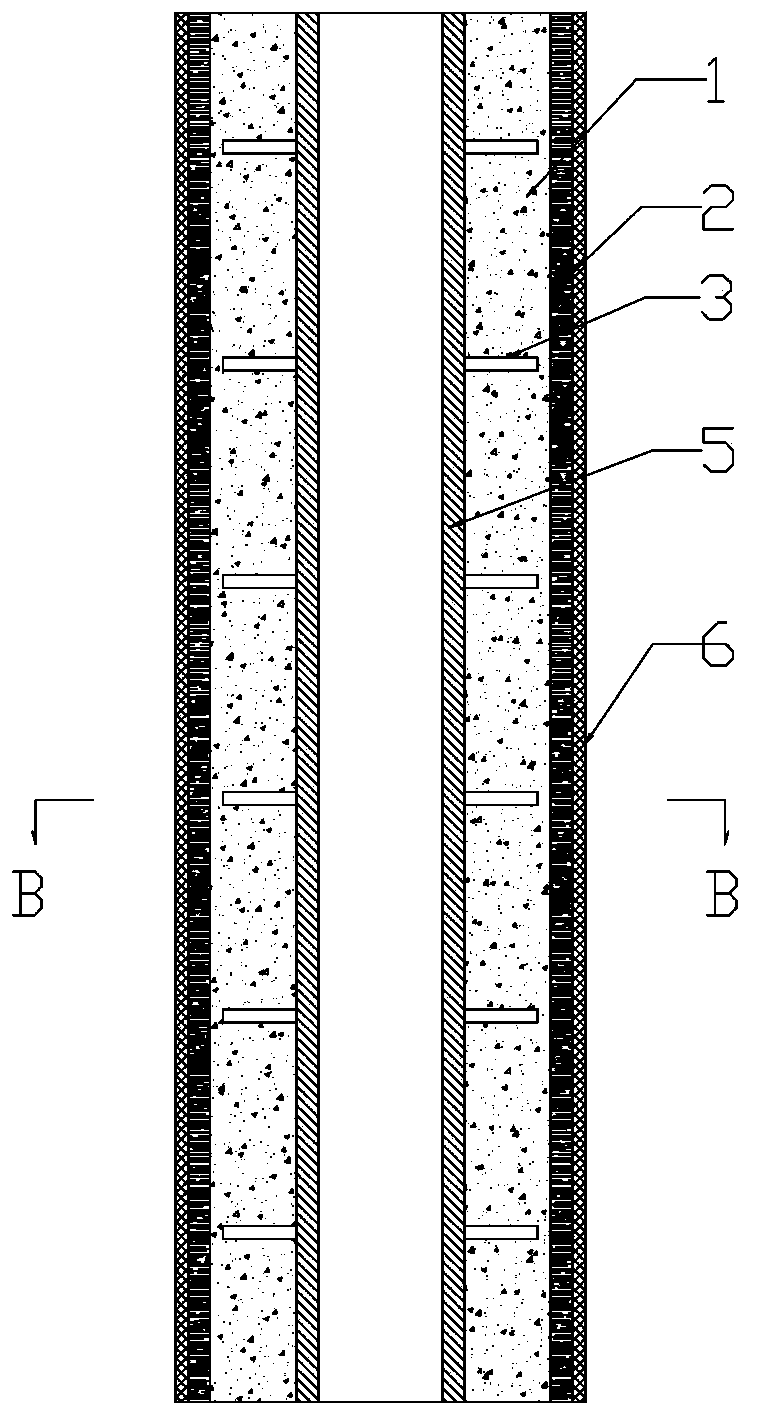

[0059] A walking-type heating furnace beam and column refractory and heat-insulating lining structure for heating high-temperature oriented silicon steel, including metal tubes 5 forming the foundation of the furnace beam or column, wherein the metal tubes 5 forming the foundation of the furnace beam are arranged at intervals along the axial direction. The heat-resistant spacer 4, the outer wall of the metal pipe 5 is evenly distributed with metal anchors 3 along the axial and circumferential directions, and the outer wall of the metal pipe 5 is poured with a fire-resistant insulation layer 1 integrated with the metal anchor 3, and the fire-resistant insulation layer 1 The outside is also covered with an anti-slag layer 2 and an anti-oxidation coating 6 in turn.

[0060] The metal anchor 3 has a V-shaped structure, its diameter is 6-8 mm, and its top is 5-10 mm away from the outer surface of the refractory insulation layer 1; the heat-resistant pad 4 is 20-40 mm higher than the...

Embodiment 2

[0069] In this example, the structure of the refractory and heat-insulating lining of the walking-type heating furnace for heating high-temperature oriented silicon steel is the same as that of Example 1, except that:

[0070] Lightweight and high-strength heat-insulating refractory castable, its raw materials include by weight percentage:

[0071] 35% lightweight mullite aggregate, 10% aluminum-rich spinel hollow spheres, 5% andalusite, 8.75% aluminum-rich spinel powder, 5% kyanite powder, 8% silica powder, 10% ρ-Al 2 o 3 Micropowder, 12% pure calcium aluminate cement, 6% refractory fiber, 0.05% sodium hexametaphosphate, 0.15% FS20 refractory castable water reducing agent, 0.04% water-soluble WD-10 silane coupling agent and 0.01 % defoamer.

[0072] Wherein, the Al of the lightweight mullite aggregate 2 o 3 Content≥60%, bulk density of 1~5mm particles≤1.0g / cm 3 , consisting of two particle gradations with a particle size greater than 3mm and less than or equal to 5mm and ...

Embodiment 3

[0078] In this example, the structure of the refractory and heat-insulating lining of the walking-type heating furnace for heating high-temperature oriented silicon steel is the same as that of Example 1, except that:

[0079] A light-weight high-strength heat-insulating refractory castable, its raw materials include by weight percentage:

[0080] 35% lightweight mullite aggregate, 10% aluminum-rich spinel hollow spheres, 8% andalusite, 5% aluminum-rich spinel powder, 6% kyanite powder, 7% silica powder, 8% ρ-Al 2 o 3 Micropowder, 16% pure calcium aluminate cement, 4.74% refractory fiber, 0.1% sodium hexametaphosphate, 0.1% FS20 refractory castable water reducer, 0.045% water-soluble WD-10 silane coupling agent and 0.015 % defoamer.

[0081] Wherein, the Al of the lightweight mullite aggregate 2 o 3 Content≥60%, bulk density of 1~5mm particles≤1.0g / cm 3 , composed of particle gradation with a particle size of 1~3mm, the particle size of the alumina-rich spinel hollow sph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com