Control method for improving anti-sticking performance and connection strength of round thread oil pipe and bushing

A control method and technology of connection strength, applied in casing, drill pipe, earth-moving drilling and other directions, can solve problems such as the influence of thread connection strength and sealing performance, weaken the anti-galling performance of joints, and increase thread gaps, etc. The effect of improving the anti-galling performance, significantly reducing casing accidents, and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

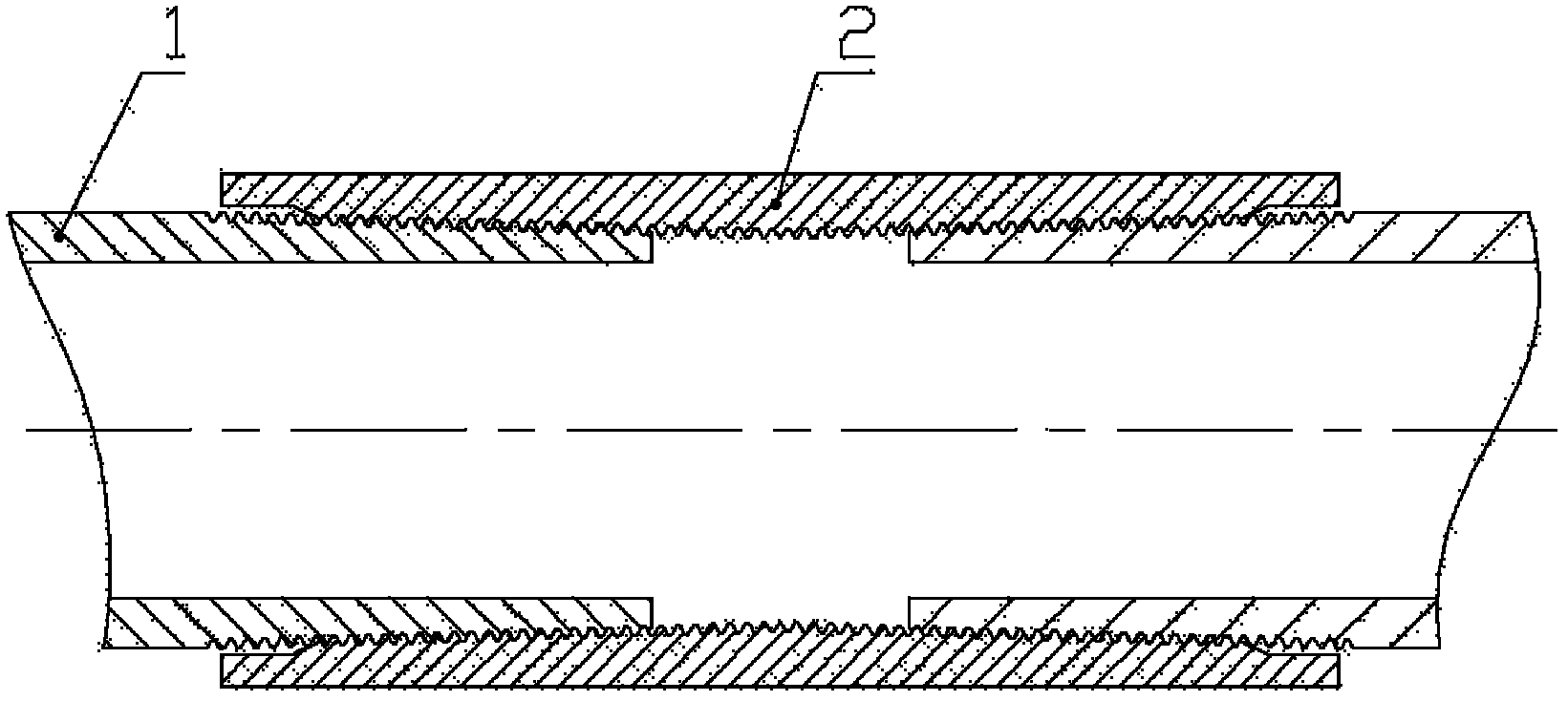

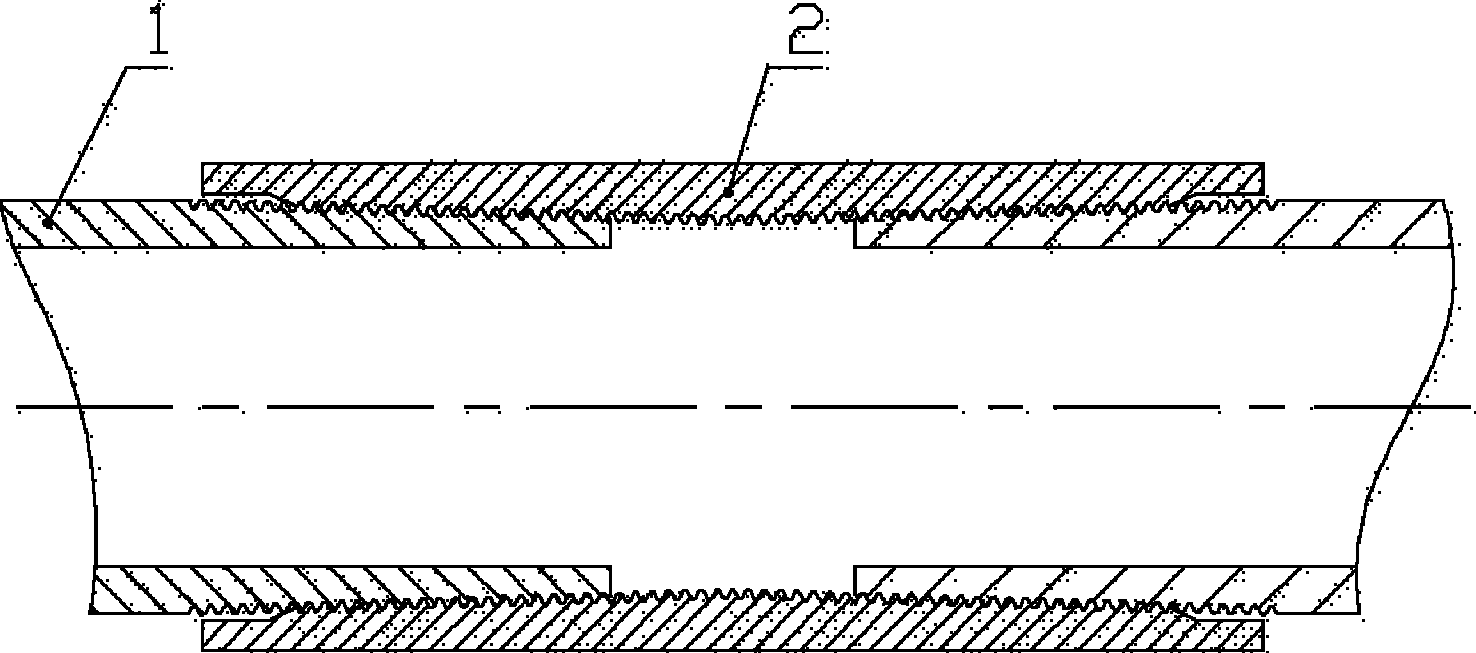

[0030] The embodiment of the present invention provides a comprehensive control method for improving the anti-seize performance and connection strength of API round thread oil / casing at the same time, see figure 1 , the control method includes controlling the yield strength of the material of the oil / casing 1 and the coupling 2 and controlling the parameters of the internal and external threads, and the internal and external threads are specifically the internal thread of the coupling 2 and the external thread of the oil / casing 1. The embodiment of the present invention is aimed at the control method of the API round thread oil casing, and other parameters not mentioned are all controlled according to the requirements of the API standard.

[0031] Slippage is essentially the yield deformation of the connection between the internal and external threads. In the final analysis, it is the failure of the material. Therefore, the yield strength of the material is one of the most impo...

Embodiment 2

[0041] In order to ensure that the API round thread oil / casing anti-seize performance and connection strength are improved in a balanced manner, this embodiment quantitatively controls various parameters on the basis of embodiment 1.

[0042] The yield strength of the control oil / casing 1 and coupling 2 materials described in the embodiment of the present invention is specifically:

[0043] The minimum value of the yield strength of the control oil / casing 1 material is 8-12% higher than the minimum value specified by the API Spec 5CT standard, and the minimum value of the yield strength of the control coupling 2 material is higher than the minimum value of the yield strength of the oil / casing 1 material 1-3%.

[0044] The control internal and external thread parameters described in the embodiments of the present invention are specifically:

[0045] Controlling the taper of the internal and external threads: the diameter increment per meter length of the internal and external ...

Embodiment 3

[0067] The control of APIΦ139.7×7.72mm N80 round thread casing 1 and coupling 2 is carried out in the following aspects:

[0068] (1) Material yield strength of control casing 1 and coupling 2:

[0069] The minimum yield strength of the casing material is controlled by 10% higher than the minimum value specified in the API Spec 5CT standard, that is, the yield strength of the casing 1 material is controlled within the range of 607-758MPa; the minimum yield strength of the coupling 2 material is within the API Spec The minimum value specified in the 5CT standard is 12% higher than the control, that is, the yield strength of the coupling material is controlled within the range of 618-758MPa.

[0070] (2) Geometric dimensions of control casing 1:

[0071] ① Outer diameter: The outer diameter deviation is controlled within the range of 0-+1%D, that is, the outer diameter of the casing is controlled within the range of φ139.7-141.10mm.

[0072] ②Wall thickness: The minimum value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com