Aqueous antifouling adhesive preventing coating and production method thereof

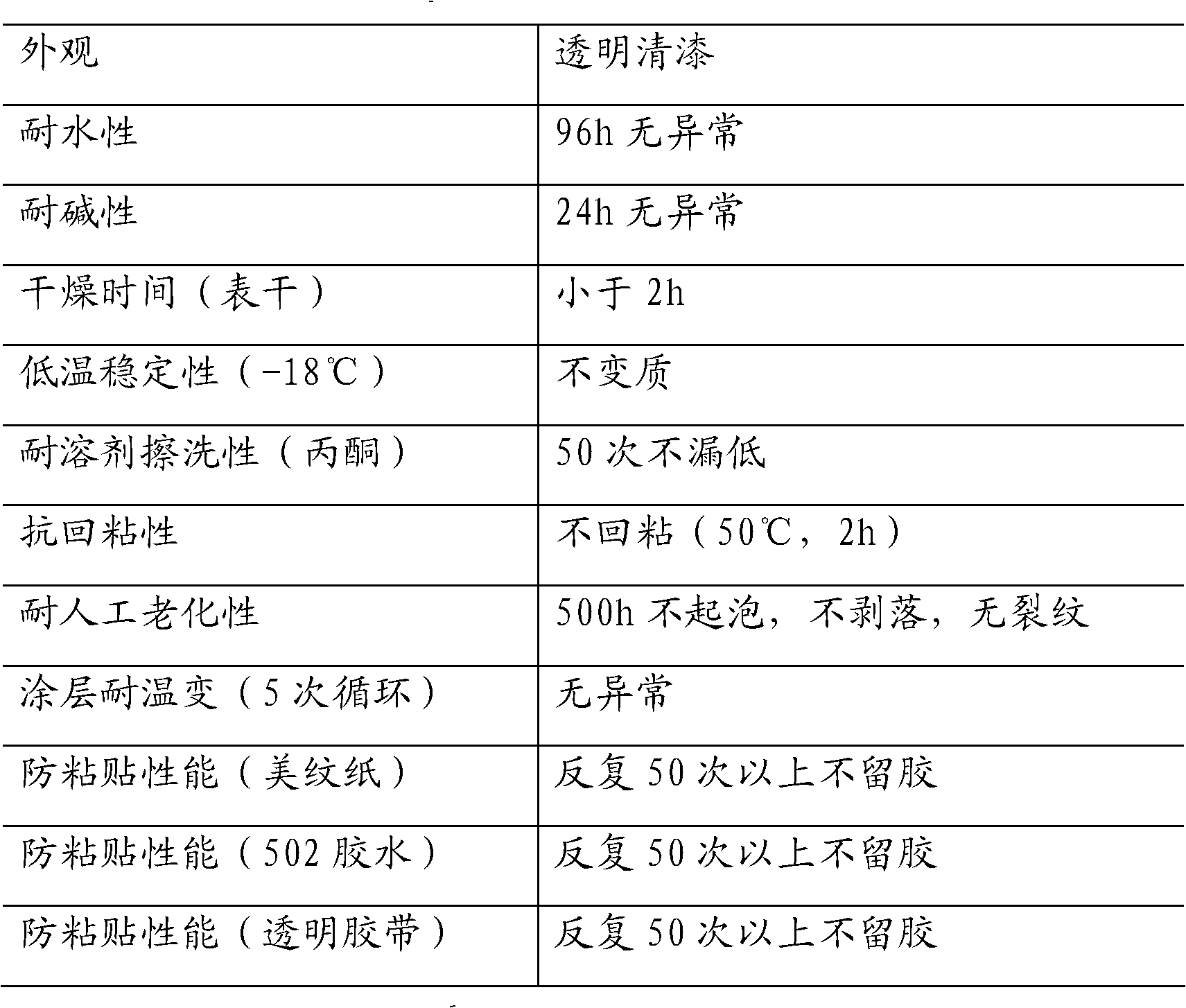

An anti-sticking and coating technology, applied in the field of coatings, can solve the problems of unsuitability for indoor use, high organic solvent content, environmental pollution, etc., and achieve the effects of excellent acid, alkali and salt resistance, excellent anti-sticking performance, and long-lasting paint film performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

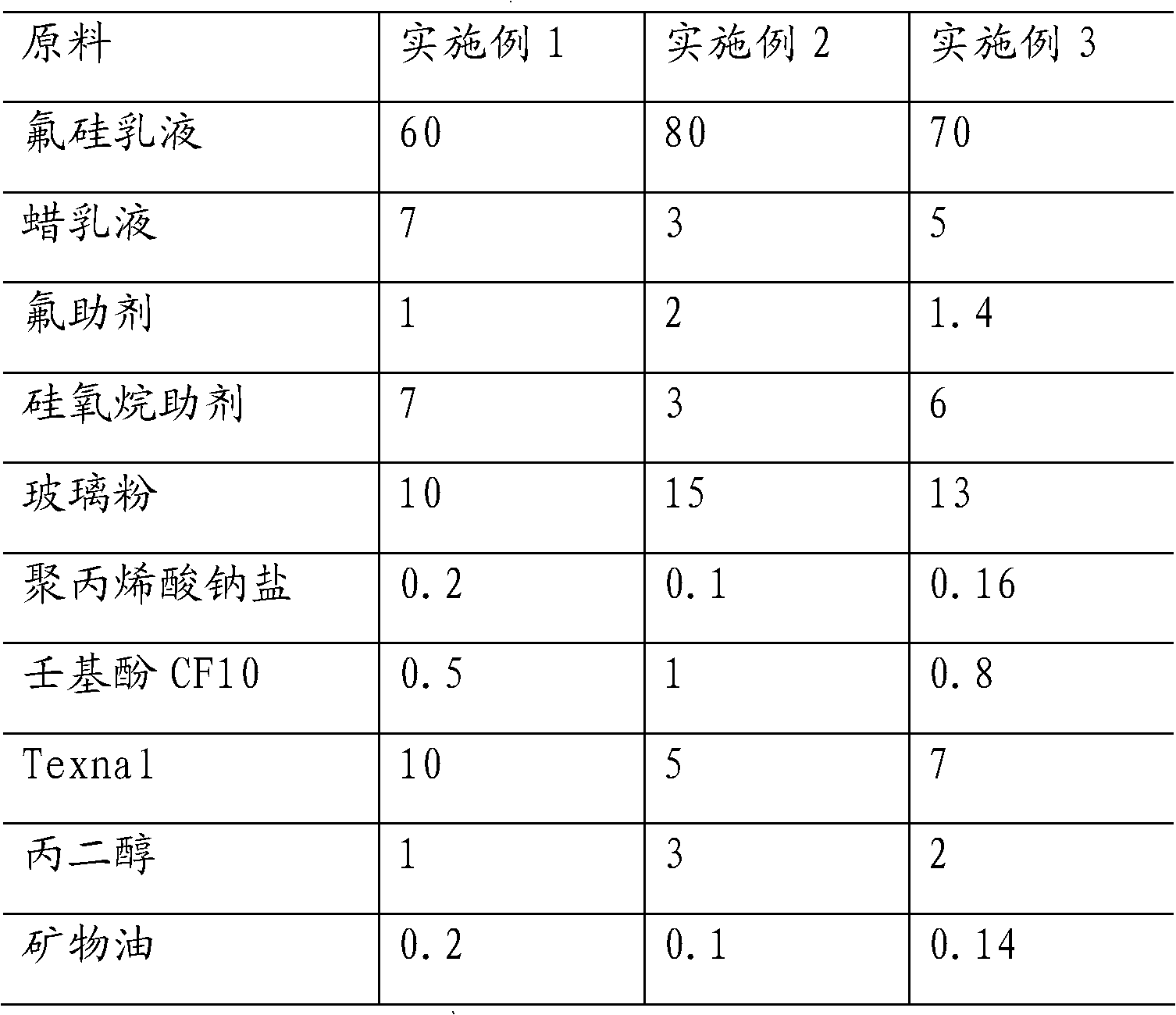

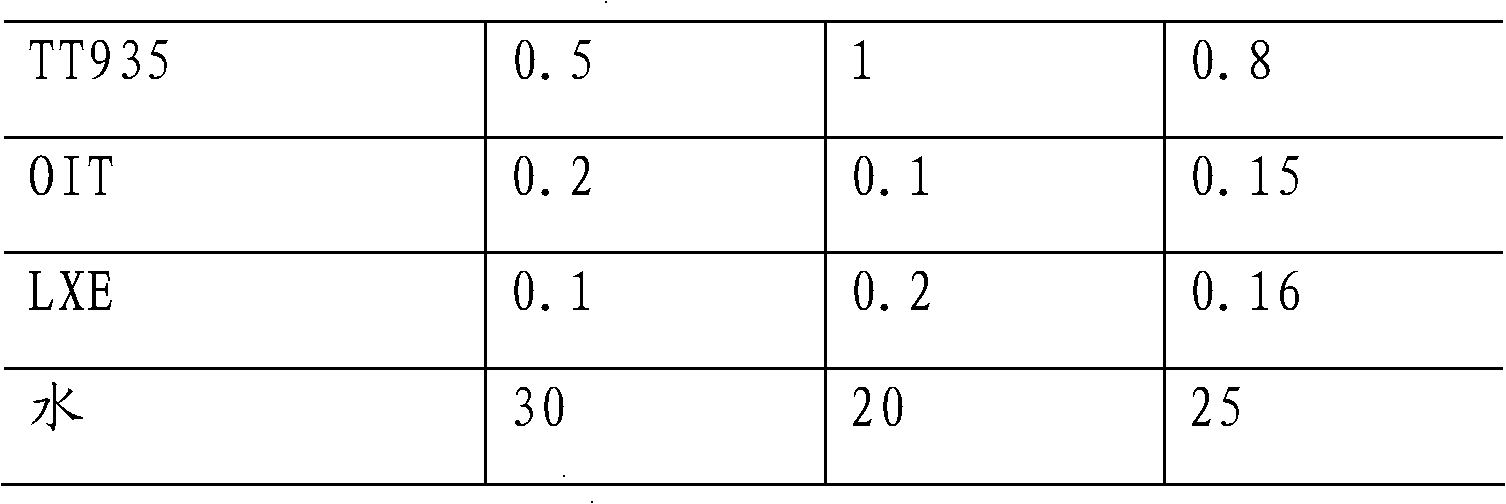

[0054] The present invention will be described in detail below in conjunction with specific embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0055] It should be noted that the specific manufacturers of the raw materials used in the following examples are respectively:

[0056] 1. The polymer emulsion can be fluorine-silicon modified acrylate emulsion from Weihai Xinyuan Chemical Company, with a solid content of about 45% and a glass transition temperature of 25°C.

[0057] 2. The hydrophobic agent is wax emulsion of model HF200 produced by Shenzhen Haichuan Chemical Technology Co., Ltd.

[0058] 3. The first anti-adhesive agent uses the fluorine additive of the model FS-81 produced by DuPont Company.

[0059] 4. The second anti-adhesive additive is a polyether-modified hydroxyl-functional polydimethylsiloxane solution produced by BYK Company, with a hydroxyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com