Modified graphene composite namometer coating and preparation method and application thereof

A graphene composite and nano-coating technology, which is applied in coatings, polyester coatings, polyacetal coatings, etc., can solve the problems of poor anti-friction effect and poor wear resistance of resin coatings, and achieve convenient construction and improved resistance. Fastening ability, friction reduction and wear resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

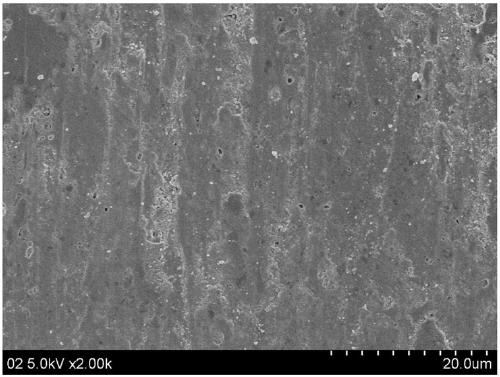

[0035] (1) Measure 10 mg of graphene oxide and add it to 100 mL of N,N-dimethylformamide, and ultrasonically disperse for 30 minutes to obtain a stable graphene oxide suspension. The suspension was stirred using a magnetic stirrer, and at the same time, 10 mL of hydrazine hydrate and 20 mL of KH550 were slowly added dropwise thereto. The suspension was ultrasonicated at 50° C. for 4 hours, cooled to room temperature after the reaction was completed, washed and dried to obtain modified graphene powder.

[0036] (2) Mix polyaldehyde resin and amino resin with n-butanol and xylene, add amine curing agent, and stir until dissolved. Wherein the polyaldehyde resin and the amino resin account for 3% and 7% of the total mass of the coating respectively by mass, and the mass percentage of the amine curing agent is 10%. The mass percentages of n-butanol and xylene are 30% and 40% respectively.

[0037] (3) Add dropwise 0.2% by mass (based on the total mass of the coating) dispersant t...

Embodiment 2

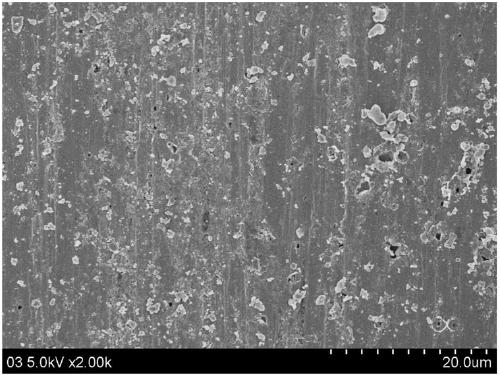

[0042] (1) Measure 30 mg of graphene oxide and add it to 100 mL of N,N-dimethylformamide, and ultrasonically disperse for 60 minutes to obtain a stable graphene oxide suspension. The suspension was stirred with a magnetic stirrer, and at the same time, 50 mL of octadecylamine and 10 mL of KH560 were slowly added dropwise thereto. The suspension was ultrasonicated at 70° C. for 3 h, cooled to room temperature after the reaction was completed, washed and dried to obtain modified graphene powder.

[0043] (2) Mix epoxy resin and polyurethane resin with n-butanol and isobutyl formate, add amine curing agent, and stir until dissolved. Wherein the epoxy resin and the polyurethane resin account for 20% and 10% by mass of the total mass of the coating respectively, and the mass percent of the amine curing agent is 15%. The mass percentages of n-butanol and isobutyl formate are 35% and 10%, respectively.

[0044] (3) In the step (2), add 1% by mass (based on the total mass of the coati...

Embodiment 3

[0046] (1) Measure 200 mg of graphene oxide and add it to 100 mL of N,N-dimethylformamide, and ultrasonically disperse for 100 min to obtain a stable graphene oxide suspension. The suspension was stirred using a magnetic stirrer, and at the same time, 70 mL of anhydrous ethylenediamine and 10 mL of KH560 were slowly added dropwise thereto. The suspension was ultrasonicated at 80° C. for 7 hours, cooled to room temperature after the reaction was completed, washed and dried to obtain modified graphene powder.

[0047] (2) Mix polyester resin, acrylic resin and phenolic resin with acetone and diisopropyl ether, add amine curing agent, and stir until dissolved. The mass percentages of polyester resin, acrylic resin and phenolic resin in the total coating mass are 5%, 15% and 8% respectively, and the mass percentage of amine curing agent is 12%. The mass percentages of acetone and diisopropyl ether are 20% and 30% respectively.

[0048] (3) Add 0.5% by mass (based on the total ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com