Antifriction and antiwear lubricant oil additive containing nano tungsten disulfide

A lubricating oil additive, tungsten disulfide technology, applied in the field of lubricating oil, can solve the problems of large surface energy, crystal structure, the effect of size and size on anti-wear and anti-friction efficiency, large surface atomic ratio, etc. Improved wear and antifriction properties, outstanding synergistic properties of antiwear and antifriction, good dispersion stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

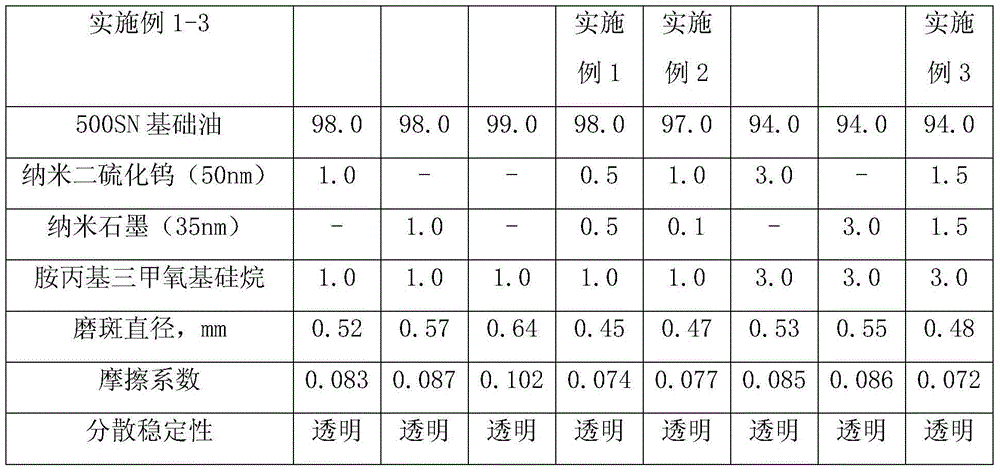

Embodiment 1-3

[0018] Add nano-tungsten disulfide with an average particle size of 50nm, nano-graphite with an average particle size of 35nm, and aminopropyltrimethoxysilane successively into mineral base oil 500SN in different weight percentage concentrations, and after ultrasonic heating and stirring, Examples 1-3 are obtained. , to evaluate the anti-wear and anti-friction properties and dispersion stability of different nano-lubricating oil formulations. Using a four-ball testing machine to measure the average wear scar diameter and friction coefficient to evaluate the anti-wear and anti-friction performance of nano-composite additives in lubricating oil. Test conditions: GCr15 steel ball, rotating speed 1450r / min, room temperature, long grinding time 60min, load 392N . The dispersion stability of nano-additives in base oil, after ultrasonic heating, stirring, dispersing and settling, observe the transparency of the mixed liquid to distinguish the dispersion stability. Test conditions: ul...

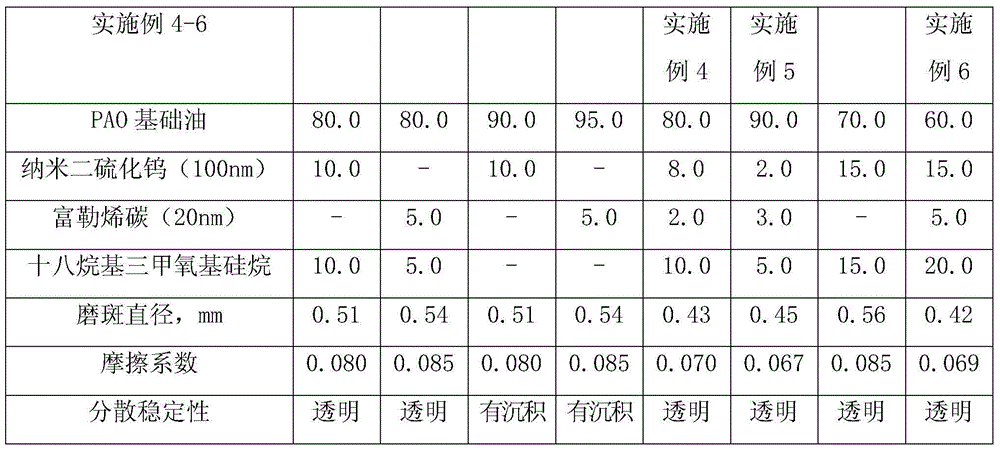

Embodiment 4-6

[0022] Nano-tungsten disulfide with an average particle size of 100nm, fullerene carbon with an average particle size of 20nm, and octadecyltrimethoxysilane were successively added to the poly-α-olefin (PAO) base oil in different weight percentage concentrations, and the ultrasonic After heating and stirring, Examples 4-6 were obtained to evaluate the anti-wear and anti-friction properties and dispersion stability of different nano lubricating oil formulations. Use a four-ball testing machine to measure the average wear scar diameter and friction coefficient to evaluate the anti-wear and anti-friction performance of nanocomposite additives in lubricating oil. Test conditions: GCr15 steel balls, rotating speed 1450r / min, room temperature, long grinding time 30min, load 392N . The dispersion stability of nano-additives in base oil, after ultrasonic heating, stirring, dispersing and settling, observe the transparency of the mixed liquid to distinguish the dispersion stability. Te...

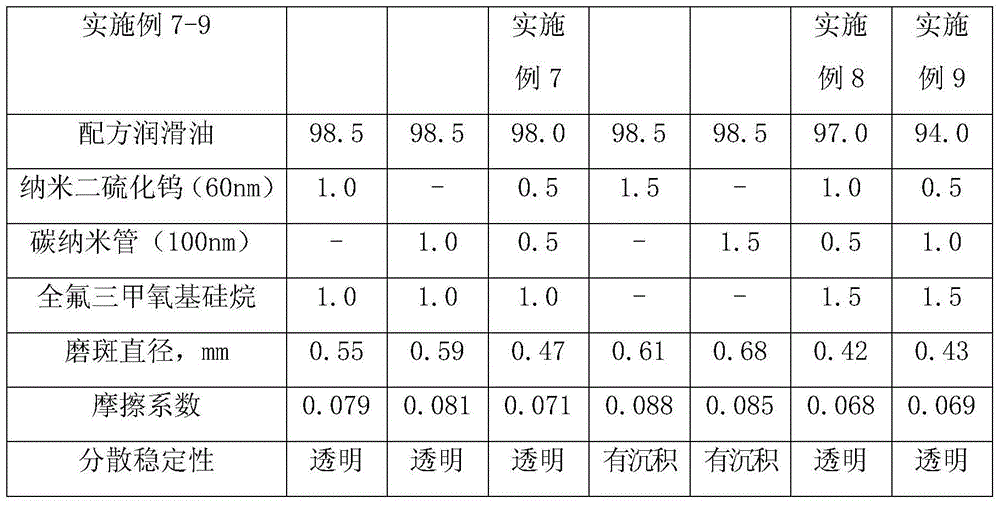

Embodiment 5-7

[0026] Nano tungsten disulfide with an average particle size of 60nm, carbon nanotubes with an average particle size of 100nm, and perfluorotrimethoxysilane with different weight percentage concentrations were successively added to the In the lubricating oil with the formulation of the nanometer lubricating oil, after ultrasonic heating and stirring, Examples 4-6 were obtained, and the anti-wear and anti-friction properties and dispersion stability of different nano lubricating oil formulations were evaluated. Using a four-ball testing machine to measure the average wear spot diameter and sintering load to evaluate the anti-wear and anti-friction performance of the nano-additive compound in lubricating oil, the test conditions: GCr15 steel ball, rotating speed 1450r / min, room temperature, long grinding time 60min, load is 490N. The dispersion stability of nano-additives in base oil, after ultrasonic heating, stirring, dispersing and settling, observe the transparency of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com