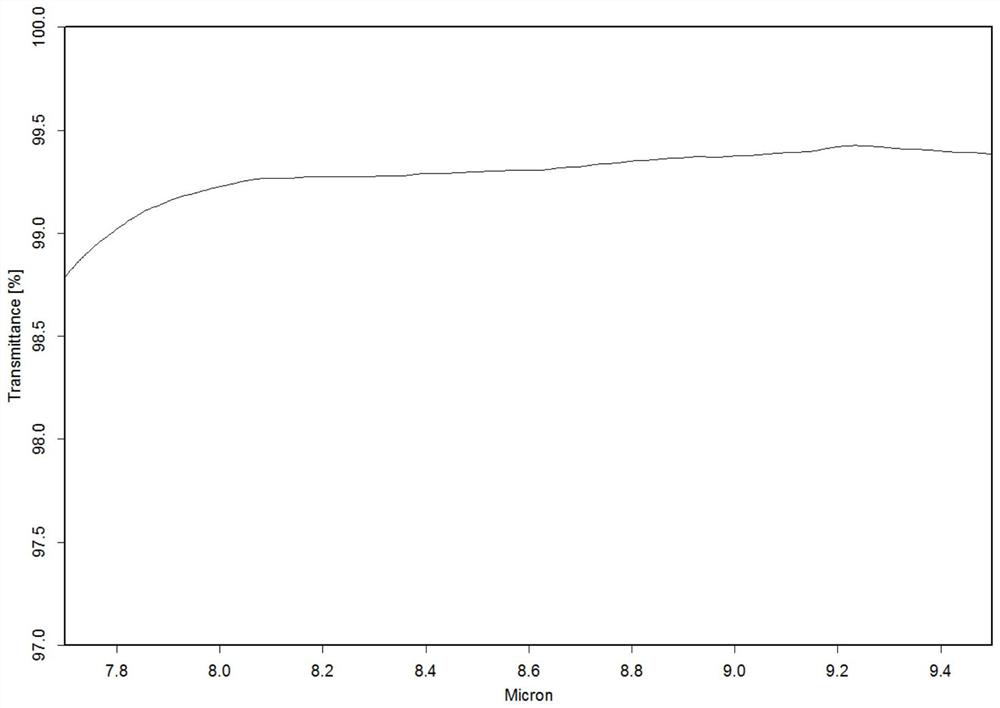

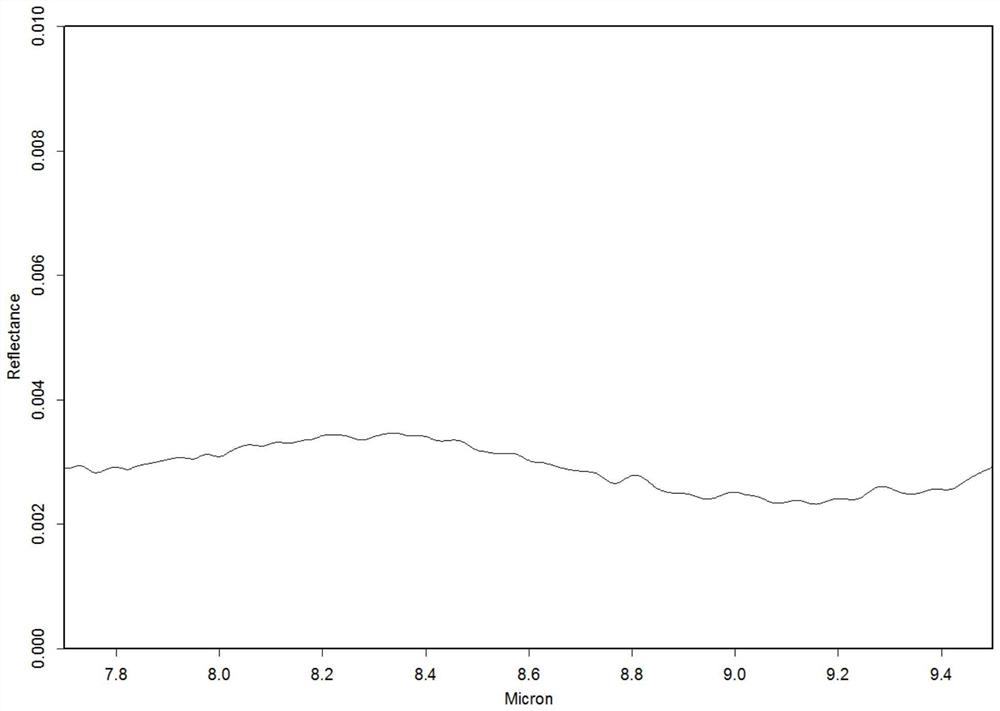

ZnSe substrate 7.7-9.5micrometer waveband high-durability antireflection film and preparation method

A durable and anti-reflection film technology, which is applied in ion implantation plating, coating, instruments, etc., can solve the problem of weak anti-salt solution immersion and anti-friction ability, and cannot well meet the requirements of new optical instruments, optical Poor performance and other problems, to improve the ability of anti-salt solution corrosion and anti-friction, improve transmittance, enhance compactness and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Choose Φ37.5mm ZnSe material lens, in the range of 7.7-9.5μm for the surface layer of the substrate, use APS ion source, fill with argon gas, gas flow rate 10sccm, bias voltage 120V, discharge voltage 80V, discharge Current 30A, coil current 2A, bombardment 6min; at 140°C, use APS ion source assisted deposition method, fill in argon gas, fill in argon gas, gas flow rate 10sccm, bias voltage 120V, discharge voltage 80V, discharge current 35A, Coil current 2A, sequentially plating a ZnSe layer with a thickness of 50nm, a Ge layer with a thickness of 122.05nm, a ZnSe layer with a thickness of 679.67nm, a Ge layer with a thickness of 154.76nm, a ZnSe layer with a thickness of 230.54nm, a YbF3 layer with a thickness of 840.00nm, and a thickness of 255nm ZnS layer; use the RF radio frequency source of the plasma chemical vapor deposition coating equipment, fill it with argon gas, the gas flow rate is 150sccm, and the power is 400W, and plasma bombards the film layer for 20 min...

Embodiment 2

[0029] Choose Φ26mm×2mm planar ZnSe material parts, use APS ion source for the surface layer of one surface of the substrate in the range of 7.7-9.5μm, fill with argon gas, gas flow rate 9sccm, bias voltage 125V, discharge voltage 90V, Discharge current 40A, coil current 4A, bombardment 6min; at 130°C, use APS ion source assisted deposition method, fill with argon gas, fill with argon gas, gas flow rate 9sccm, bias voltage 125V, discharge voltage 90V, discharge current 40A , coil current 4A, sequentially plating a ZnSe layer with a thickness of 50nm, a Ge layer with a thickness of 122.05nm, a ZnSe layer with a thickness of 679.67nm, a Ge layer with a thickness of 154.76nm, a ZnSe layer with a thickness of 230.54nm, a YbF3 layer with a thickness of 840.00nm, a thickness of 255nm ZnS layer; use the RF radio frequency source of the plasma chemical vapor deposition coating equipment, fill it with argon gas, the gas flow rate is 200sccm, the power is 500W, and plasma bombards the fi...

Embodiment 3

[0034] Select Φ40mm×3mm planar ZnSe material parts, use APS ion source for the surface layer of one surface of the substrate in the range of 7.7-9.5μm, fill with argon gas, gas flow rate 8sccm, bias voltage 120V, discharge voltage 70V, Discharge current 25A, coil current 2A, bombardment 6min; at 150°C, use APS ion source assisted deposition method, fill with argon gas, fill with argon gas, gas flow rate 10sccm, bias voltage 120V, discharge voltage 70V, discharge current 30A , coil current 2A, sequentially plating a ZnSe layer with a thickness of 50nm, a Ge layer with a thickness of 122.05nm, a ZnSe layer with a thickness of 679.67nm, a Ge layer with a thickness of 154.76nm, a ZnSe layer with a thickness of 230.54nm, a YbF3 layer with a thickness of 840.00nm, a thickness of 255nm ZnS layer; use the RF radio frequency source of plasma chemical vapor deposition coating equipment, fill with argon gas, gas flow rate 100sccm, power 400W, plasma bombardment on the film layer, bombardm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com