Copper-radicle antifriction compound powder and method of producing the same

A technology of composite powder and manufacturing method, which is applied in the direction of coating, etc., can solve the problems of low service life, friction reduction, high temperature strength and wear resistance, etc., and achieve improved friction reduction, low cost, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

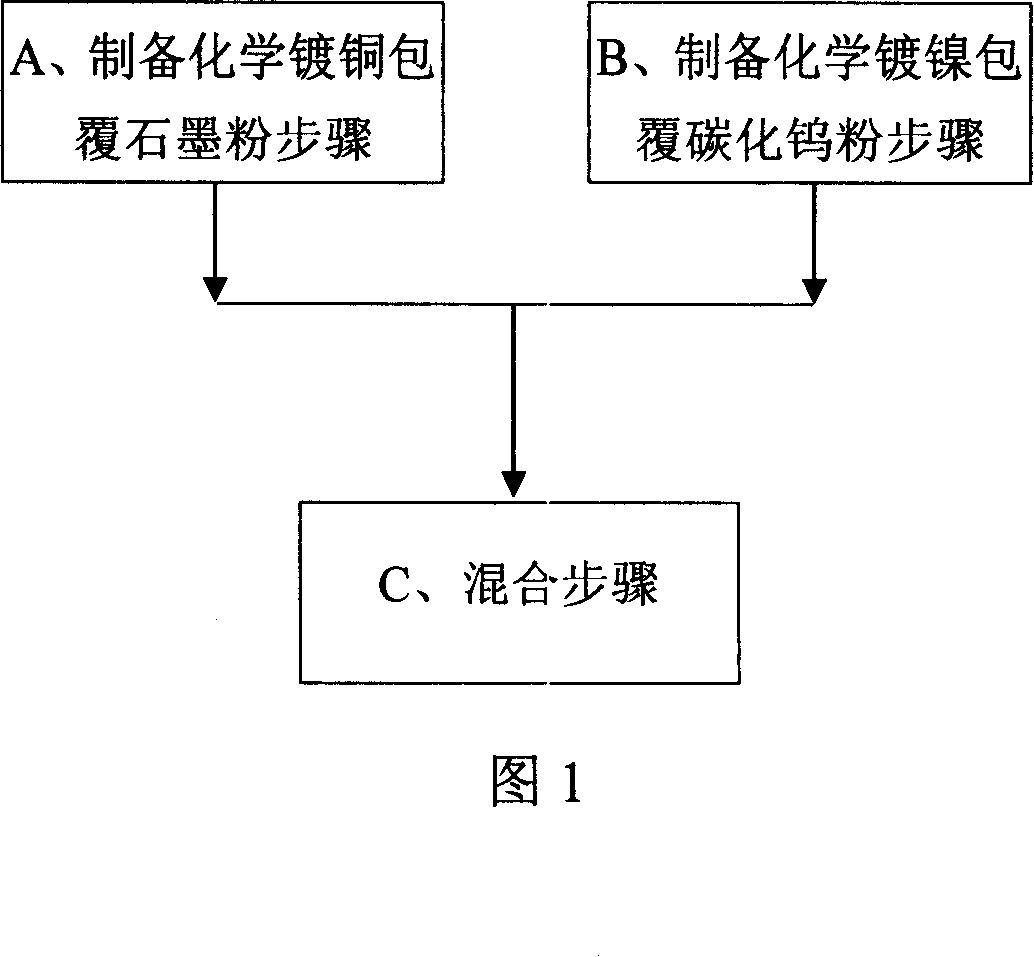

example 1

[0038] Prepare each main raw material and auxiliary raw material according to the aforementioned proportion two, and the copper powder wherein can adopt general commercial copper powder; Then prepare electroless copper-coated graphite powder, electroless-plated Nickel-coated tungsten carbide powder; then according to step C, three kinds of copper powder, electroless copper-coated graphite powder, and electroless nickel-coated tungsten carbide powder are put into a V-shaped mixer and sealed, and mixed. The mixing time is 15 Hours, Cu80%-C15%-WC2.5%-Ni2.5% copper-based anti-friction composite powder can be obtained. After conventional pressing and sintering processes, copper-based anti-friction composite materials can be made. After testing, compared with the copper-based anti-friction composite material block material made of ordinary copper-based anti-friction composite powder, the friction-reducing performance of the copper-based anti-friction composite material made of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com