Fermentation device for organic fertilizer

A fermentation equipment and organic fertilizer technology, applied in the direction of organic fertilizer, bio-organic part treatment, fertilization device, etc., can solve the problems of poor benefit, low production efficiency, secondary pollution, etc., achieve comprehensive utilization, good airtightness, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

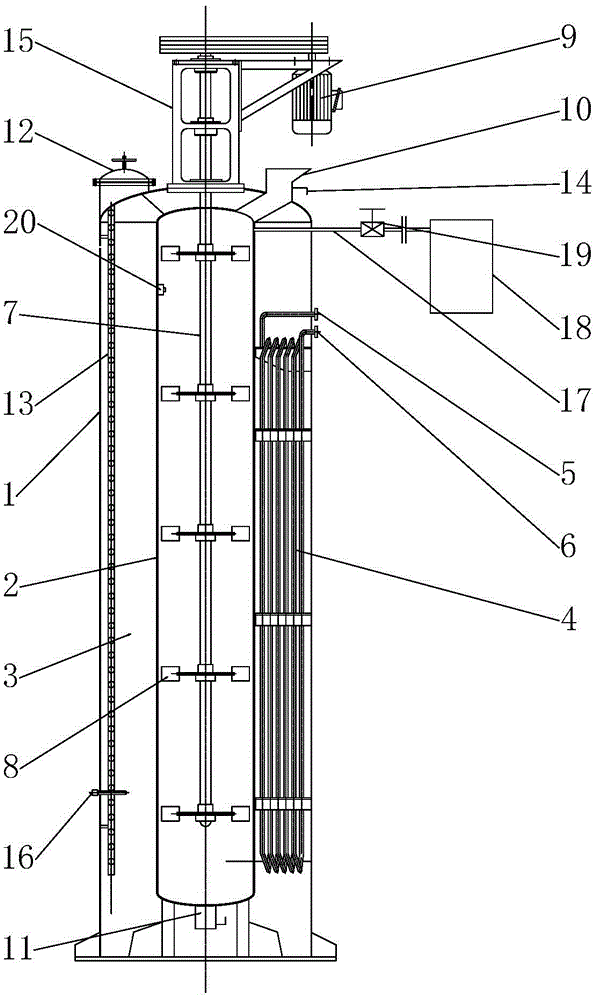

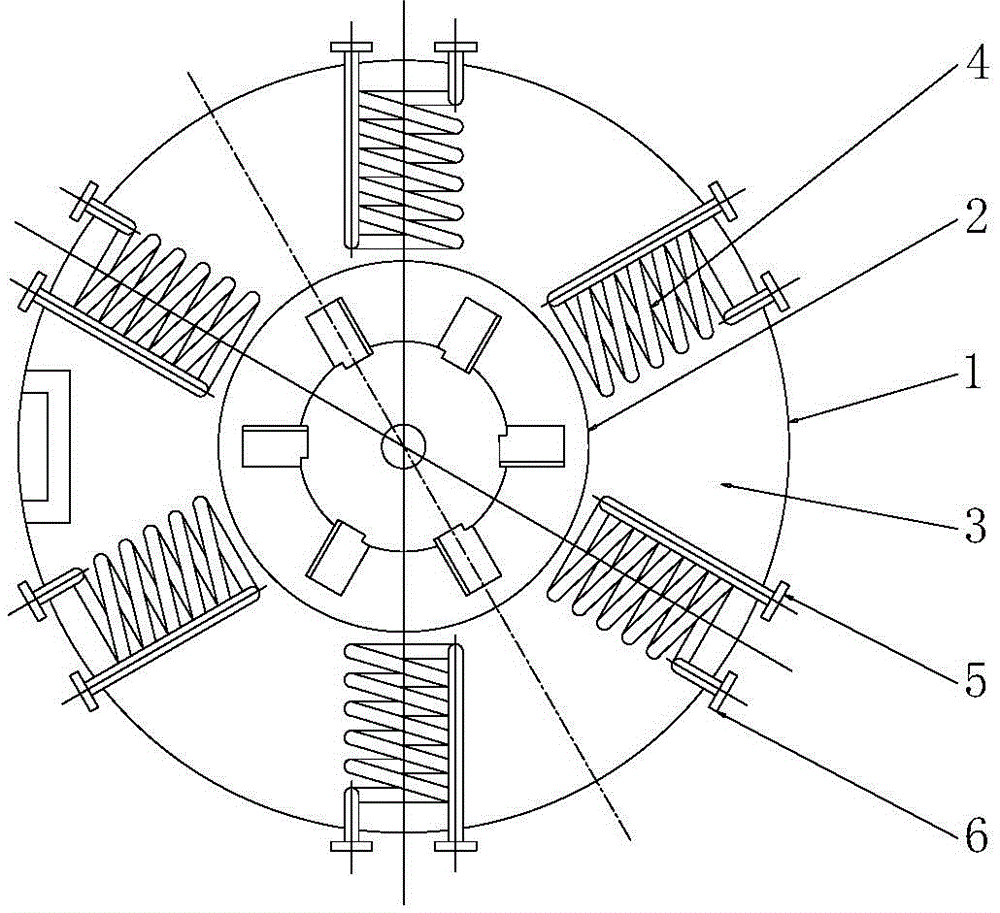

[0018] As shown in Figure 1, it is a schematic structural view of an embodiment of an organic fertilizer fermentation equipment of the present invention. The organic fertilizer fermentation equipment of this embodiment includes a coaxially arranged shell 1 and an inner tank 2, an annular cavity 3 is arranged between the outer shell 1 and the inner tank 2, and steam heating coils 4 are evenly distributed in the annular cavity 3 , the air inlet 5 and the air outlet 6 of the steam heating coil 4 are all arranged on the shell 1, and the inner tank 2 is provided with the stirring shaft 7, and the stirring blade group 8 is arranged at intervals on the stirring shaft 7, and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com