Ellipse-like rotor engine with high sealing performance

A rotary engine, ellipse-like technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of failure to change the profile structure and motion characteristics, cylinder gas leakage, and high processing costs, so as to reduce gas leakage. phenomenon, prevention of gas leakage, and effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

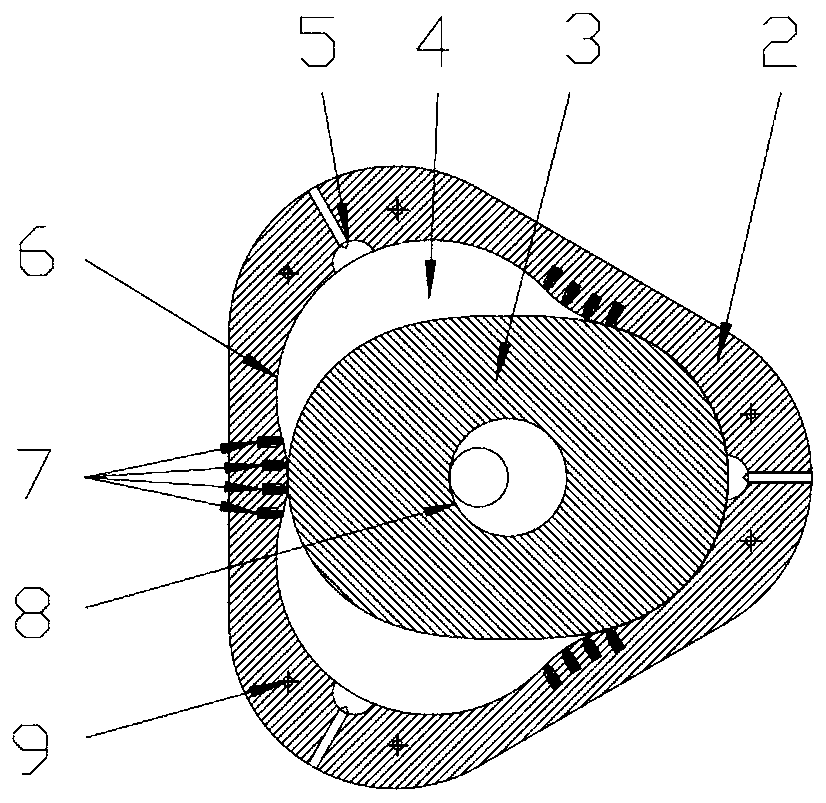

[0065] Parameters k=11, e=0.006m, q=4.5, assuming that each sealing pin column contains 4 sealing pins, and the effective distance of each sealing pin is 0.0016m, this is used as an example to describe the specific operation mode of the engine.

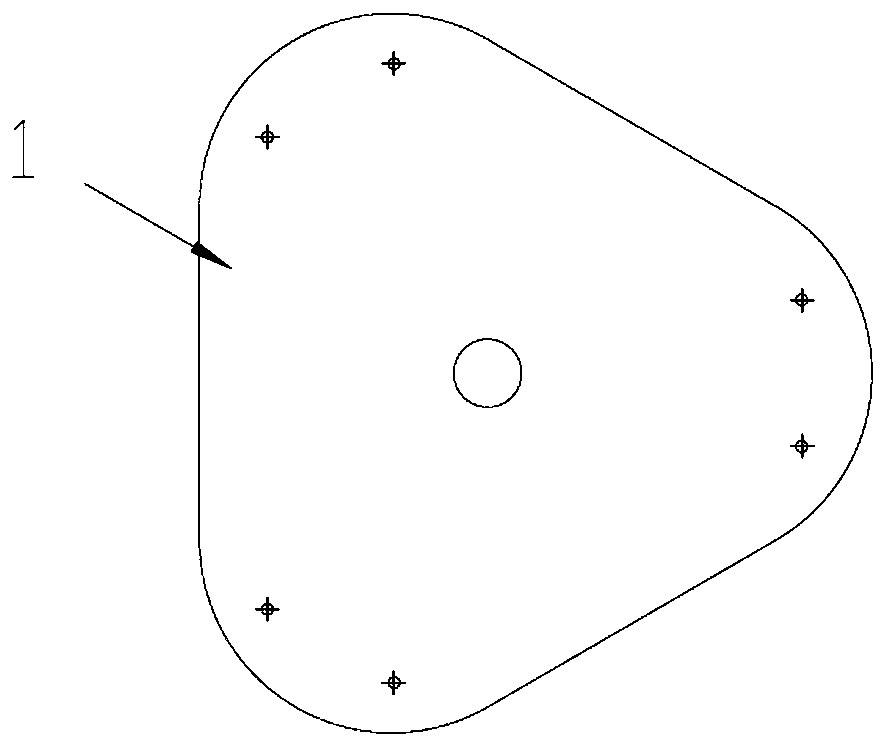

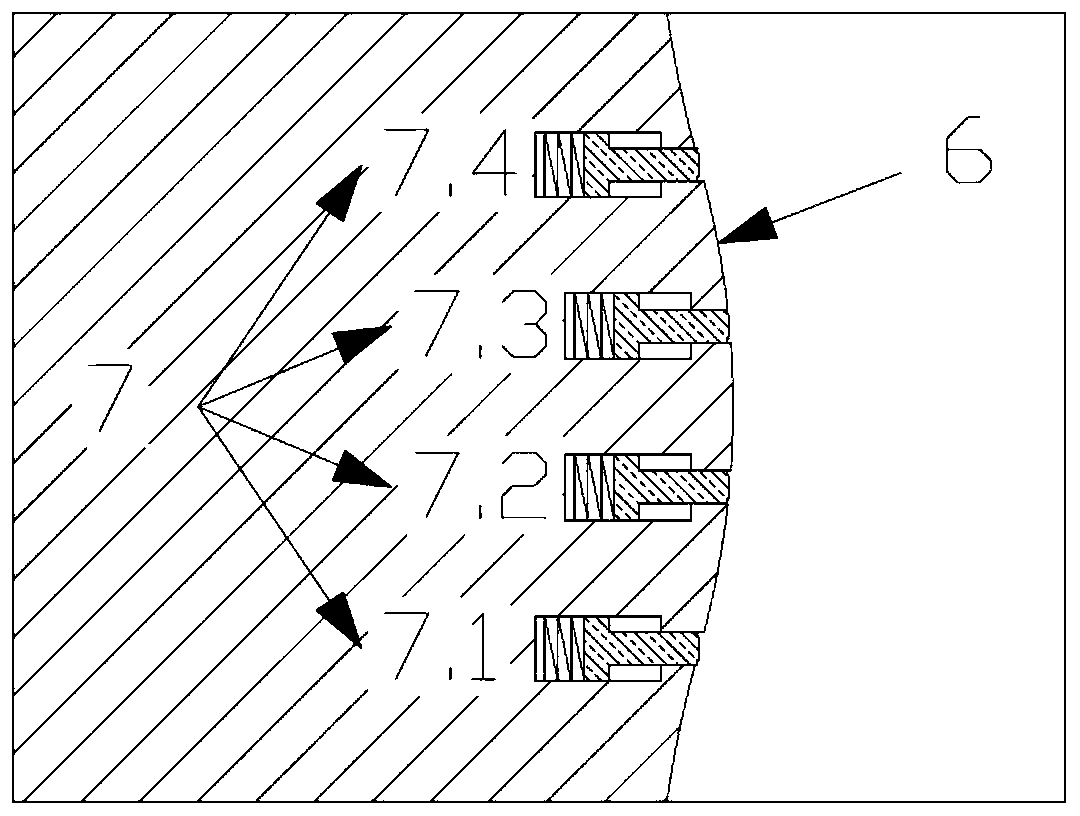

[0066] Since the overall shape of the cylinder body is 120 degrees rotationally symmetric, only 1 / 3 of it needs to be considered in this embodiment. Such as image 3 As shown, the sealing pin column 7 composed of 4 sealing pins is arranged vertically on the isolation belt 6, and the sealing pin column 7 is arranged equidistantly along the longitudinal direction. Pins 7.1-7.4. Such as Figure 5 As shown, since the distance between each sealing pin and the rotor 3 is different when the rotor 3 is in different positions, it is considered that the distance between each sealing pin and the rotor 3 changes during one cycle of the rotor 3 rotation, The first four curves in the figure represent the change curve of the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com