Submarine high-pressure oil gun

A high-pressure machine, latent technology, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of incomplete oil use, poor airtightness, no oil pumping, etc., to achieve thorough oil use and flexible operation , the effect of convenient refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

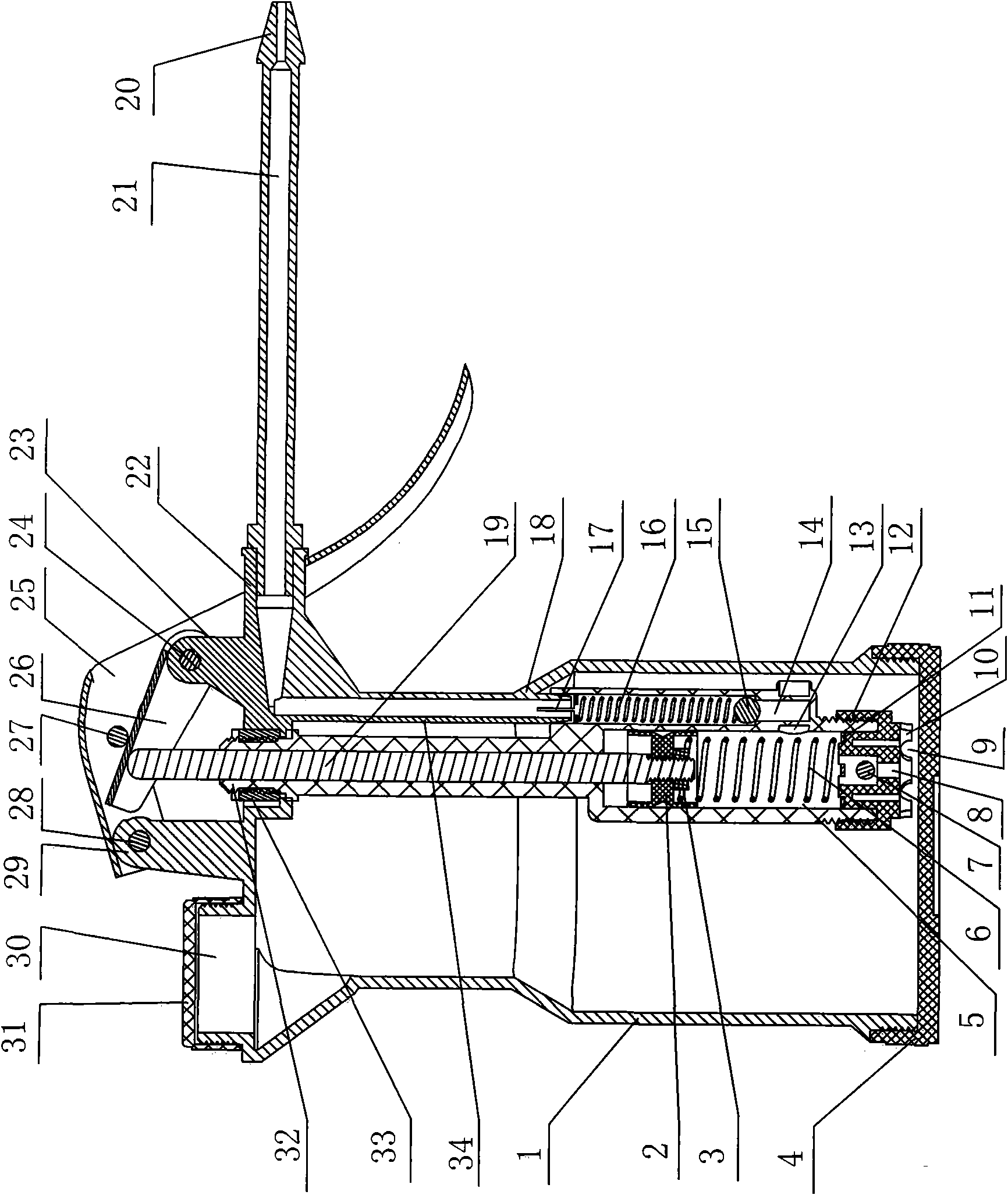

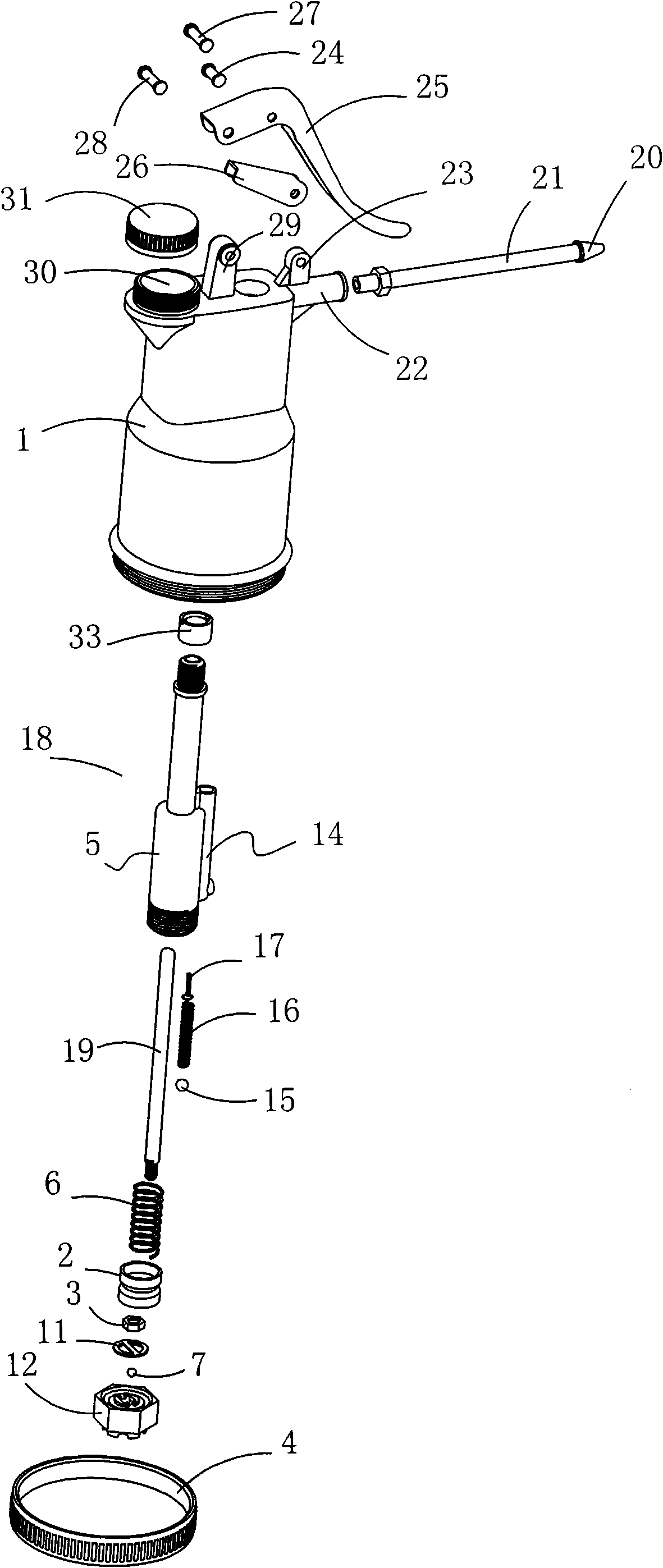

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

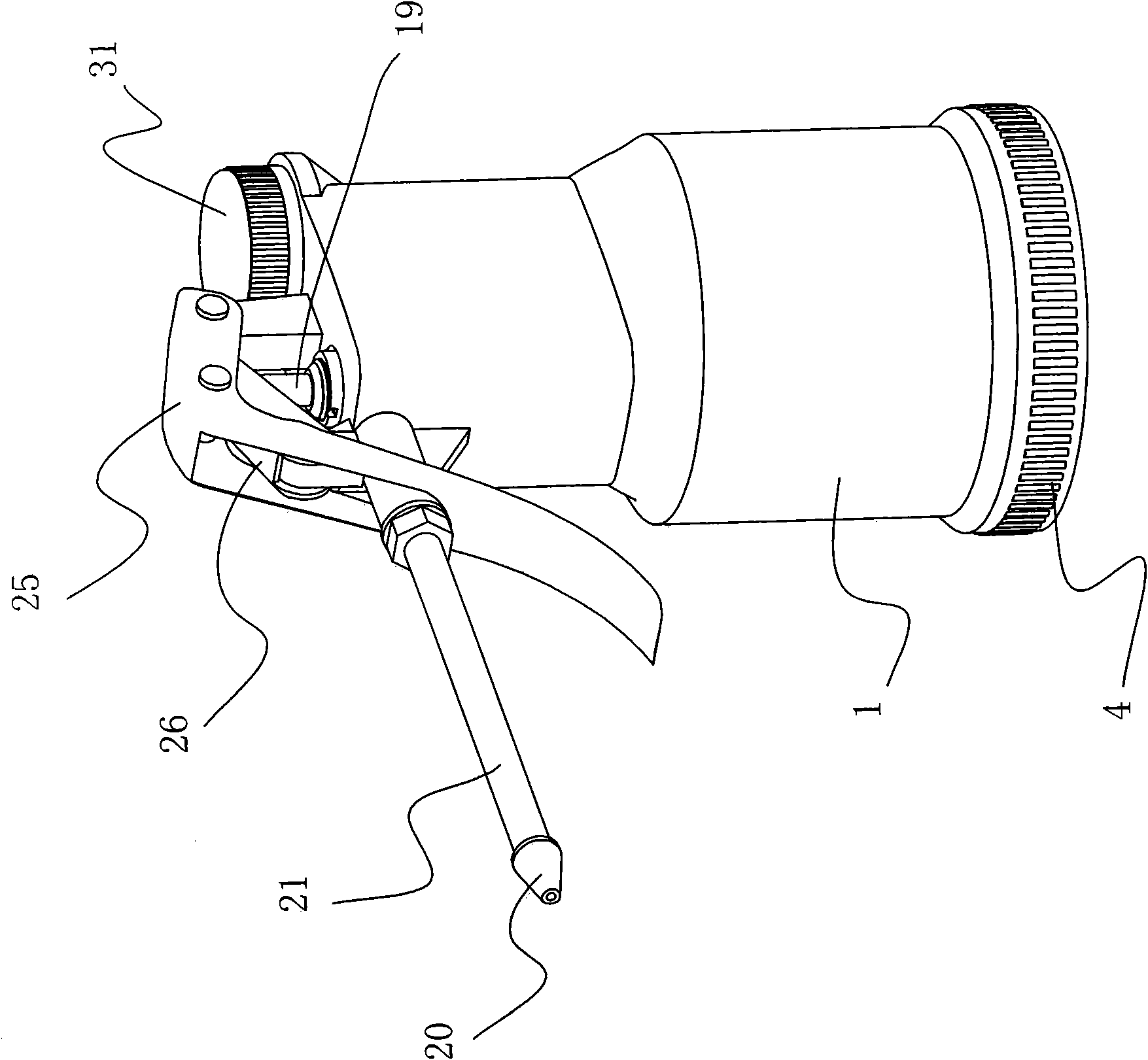

[0016] to combine Figure 1-Figure 3 As shown, the latent high-pressure oil gun of the present invention is composed of two parts, the oil storage device and the oil injection device, wherein:

[0017] Oil storage device is an oil tank 1, the bottom of oil tank is open, and a bottom cover 4 is installed, can adopt thread connection between bottom cover 4 and oil tank 1, and seal with sealing ring or sealant. The top of the oil tank 1 is formed with an opening for the piston rod 19 to pass, a gun barrel 22 (oil delivery pipe hole) connected with the spray bar, a filling hole 30 and two screws for pivoting the wrench 25 and the transmission member 26. Boss 29,23, two bosses 29,23 are all shaped on shaft holes. A sealing cover 31 is housed on the filling hole 30, and machine oil is added in the oil tank 1 from this hole. The inside of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com