Templet assembly device for mould

A module and assembly technology, applied in tires, applications, household appliances, etc., can solve the problems of cleaning tire molds, troublesome cleaning, time-consuming, etc., and achieve the effect of streamlined structure, easy and trouble-free cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

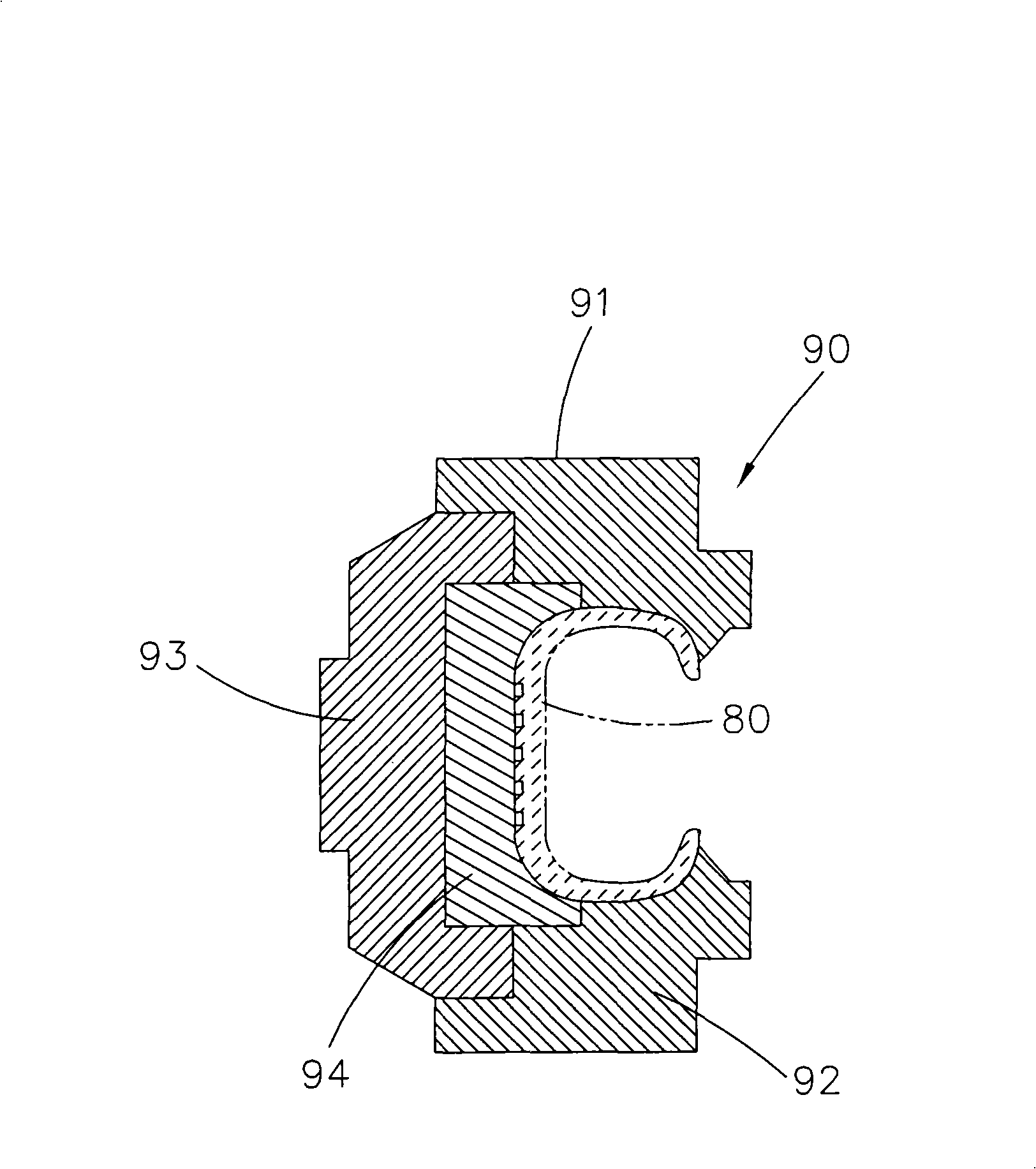

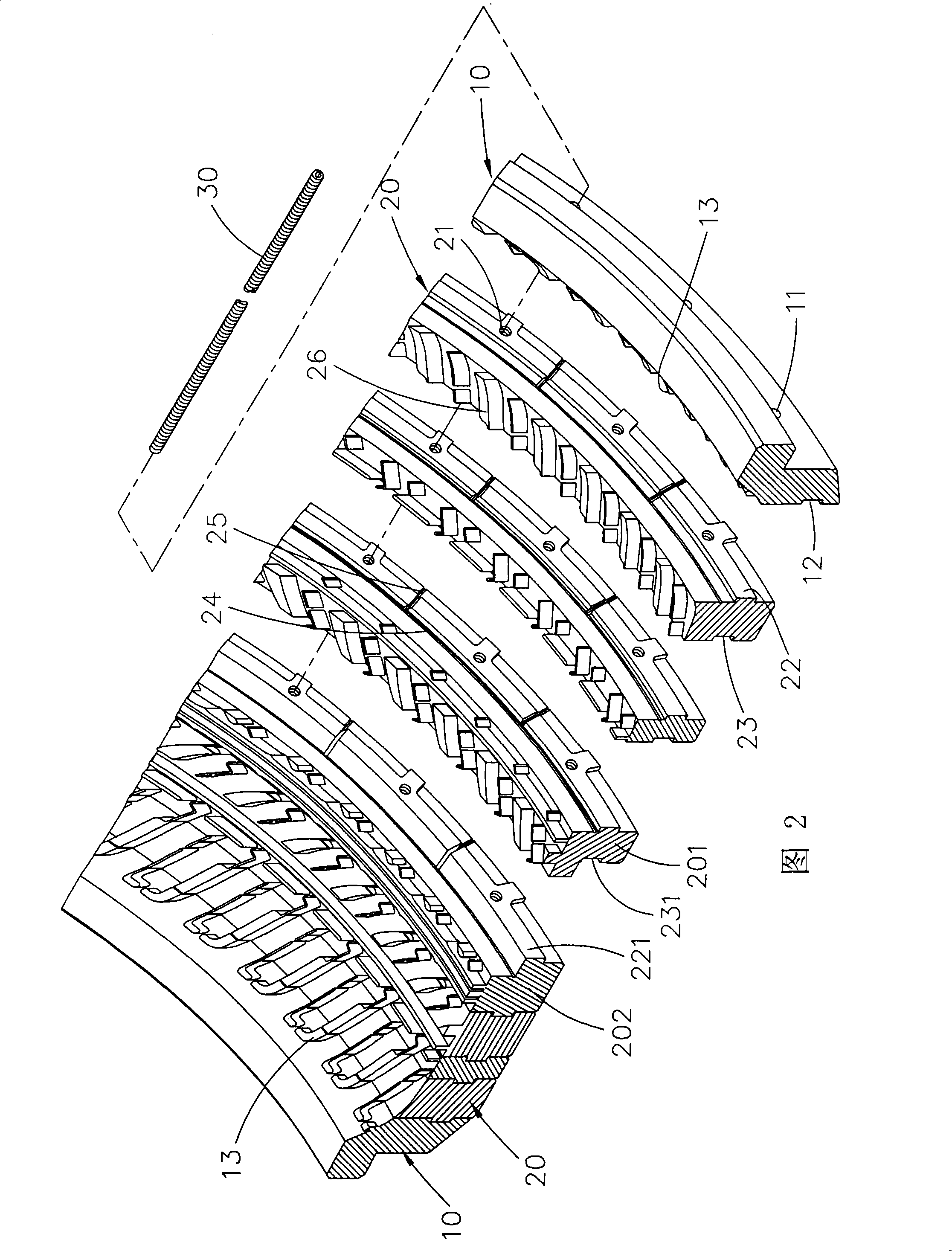

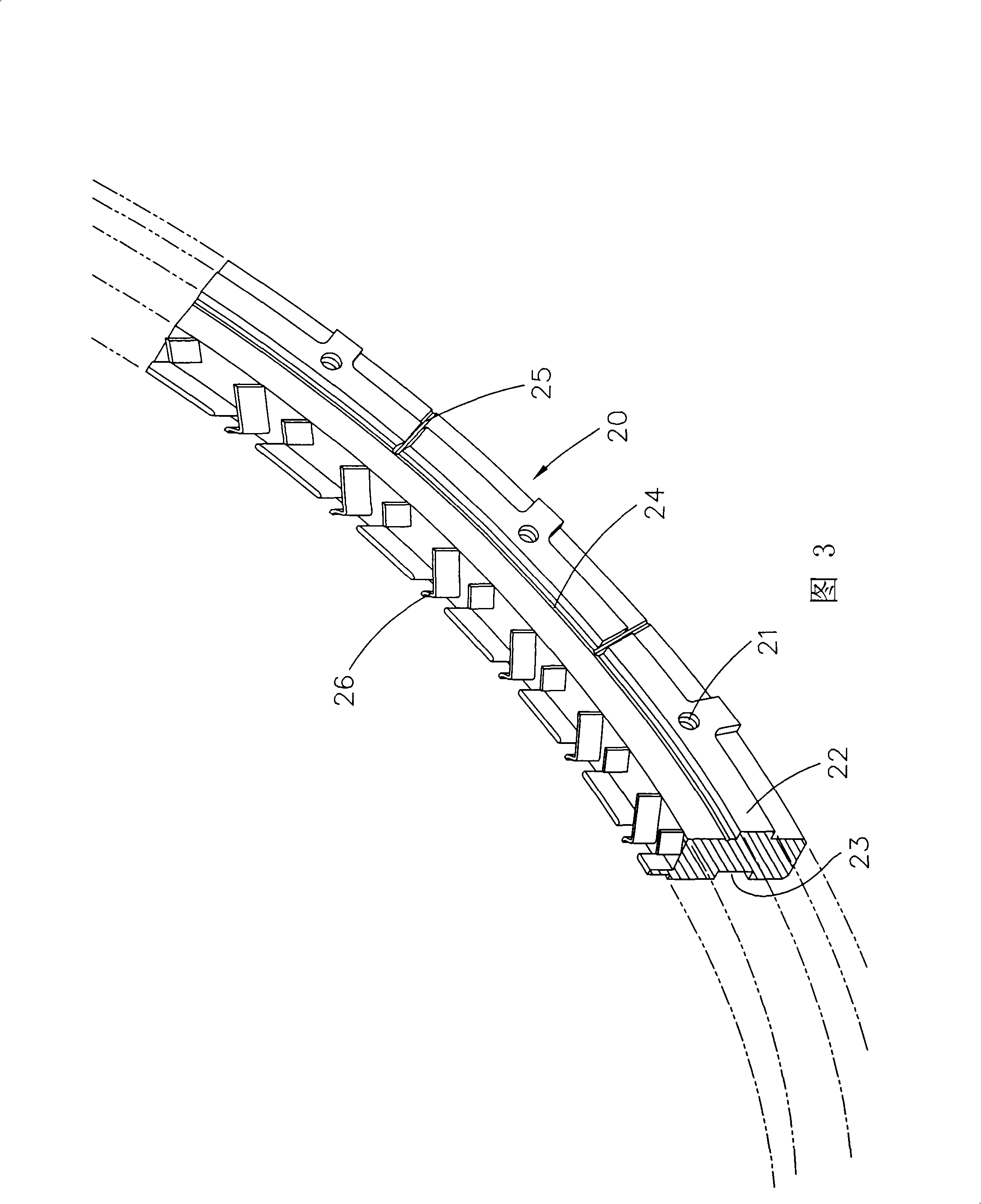

[0044] The present invention is a mold assembly device for a tire mold. Please refer to the perspective view of a partial section in FIG. It is connected into a tire mold, wherein there are two outer mold pieces 10, located on both sides, and several inner mold pieces 20 are sandwiched between the outer mold pieces 10, so the shape of the composition is like a ring with thickness, and the tire module is formed. The cross-sectional view shows that the end faces connected by the outer and inner mold sheets 10 and 20 form a meniscus relative to the cross-section of the tire, and the other side is equivalent to the longitudinal cutting ring of the tire, so the outer mold sheet 10, the inner mold The sheet 20 is an annular sheet.

[0045] Please refer to Figures 2 to 4 again, wherein the outer mold 10 is provided with a through-shaped lock hole 11 along the way, the lock hole 11 is a screw hole, and the outer mold 10 is a spacer on the side facing the inner mold 20. Concave severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com