Resistance-and-reactance-compounded exhaust silencer

A technology of exhaust muffler and resistance muffler, applied in muffler devices, machines/engines, engine components, etc., can solve the problems of increased cost investment, short service life, waste of manpower, material and financial resources, etc. High, medium and low frequency noise, stable structure, smooth exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

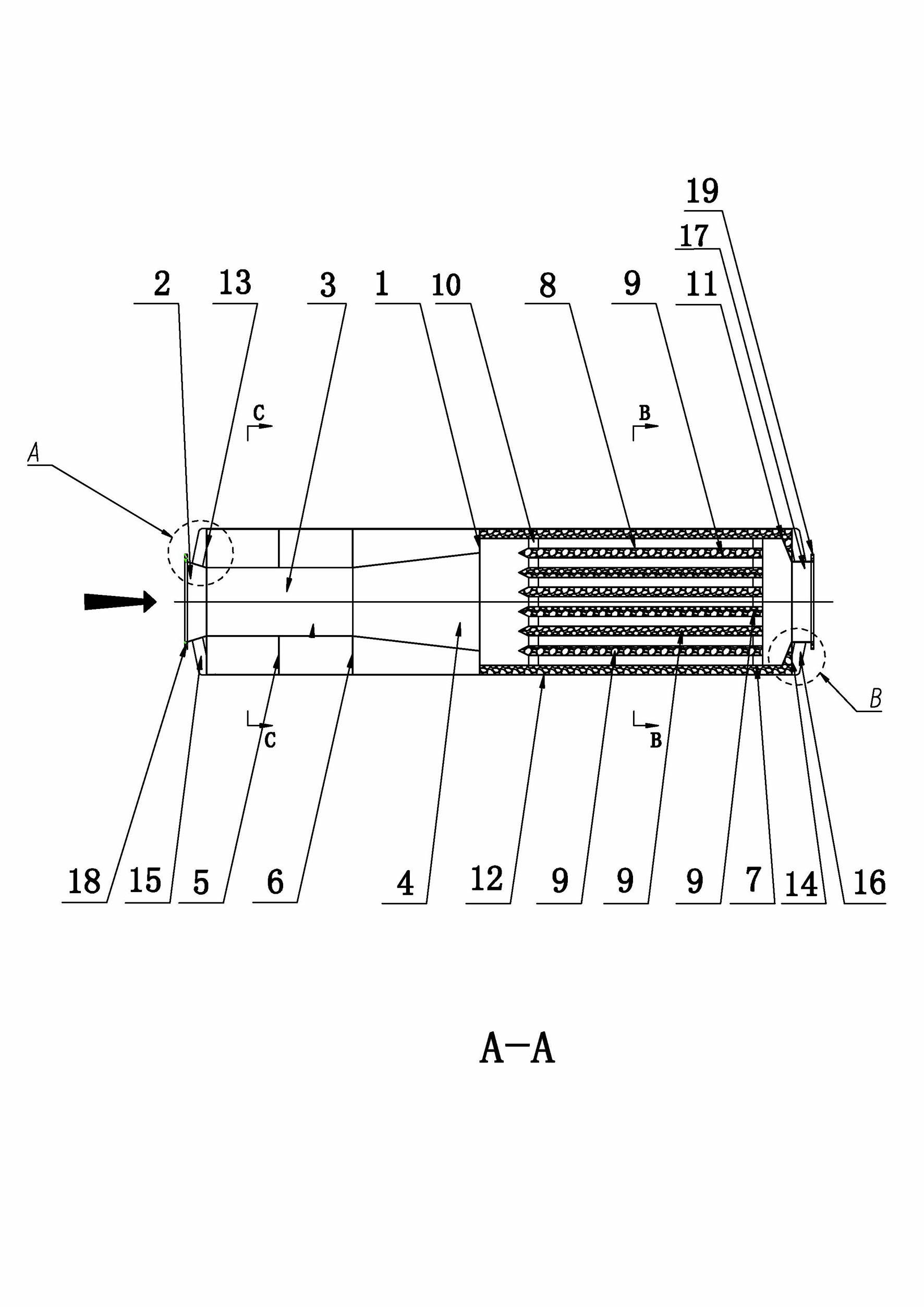

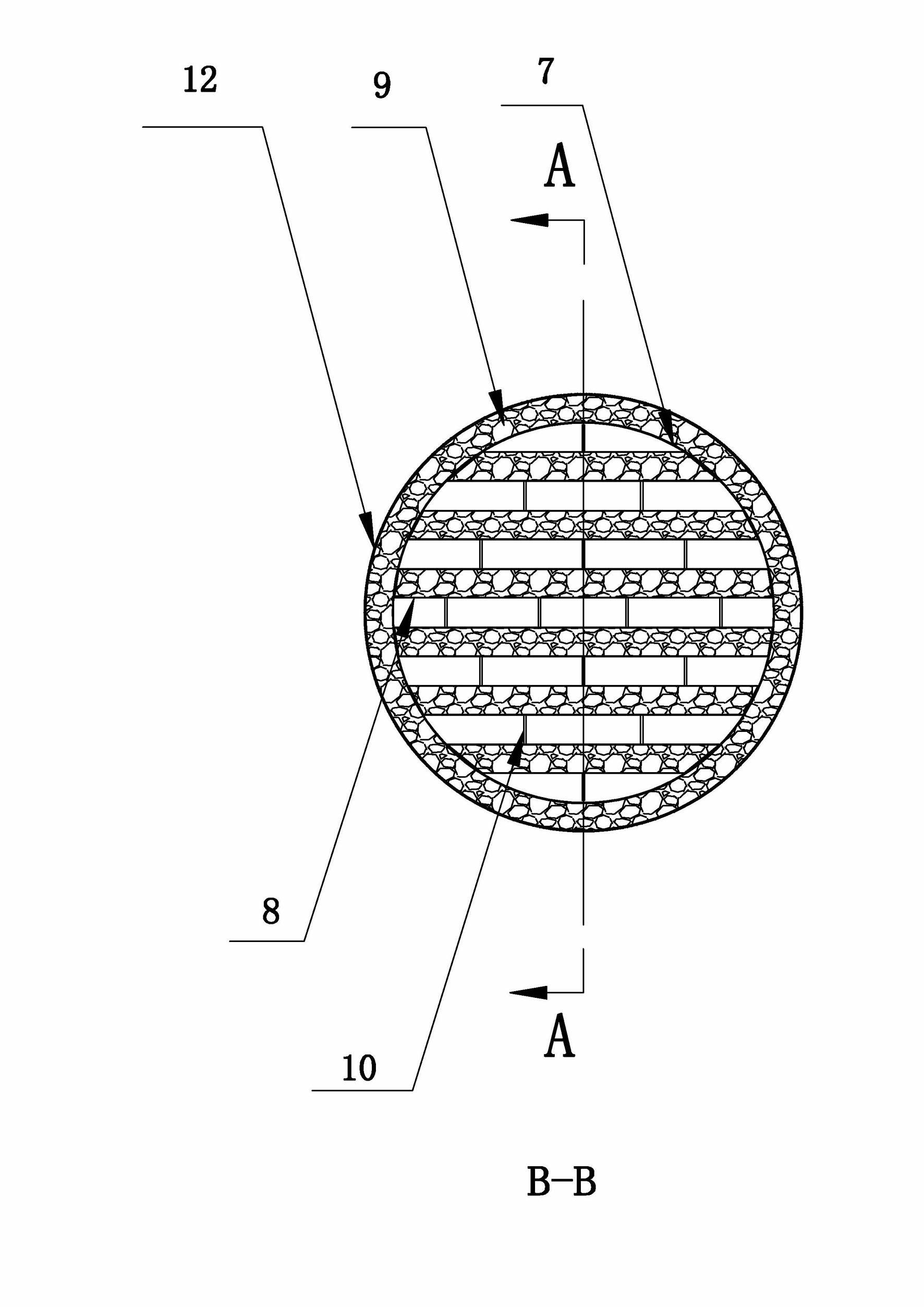

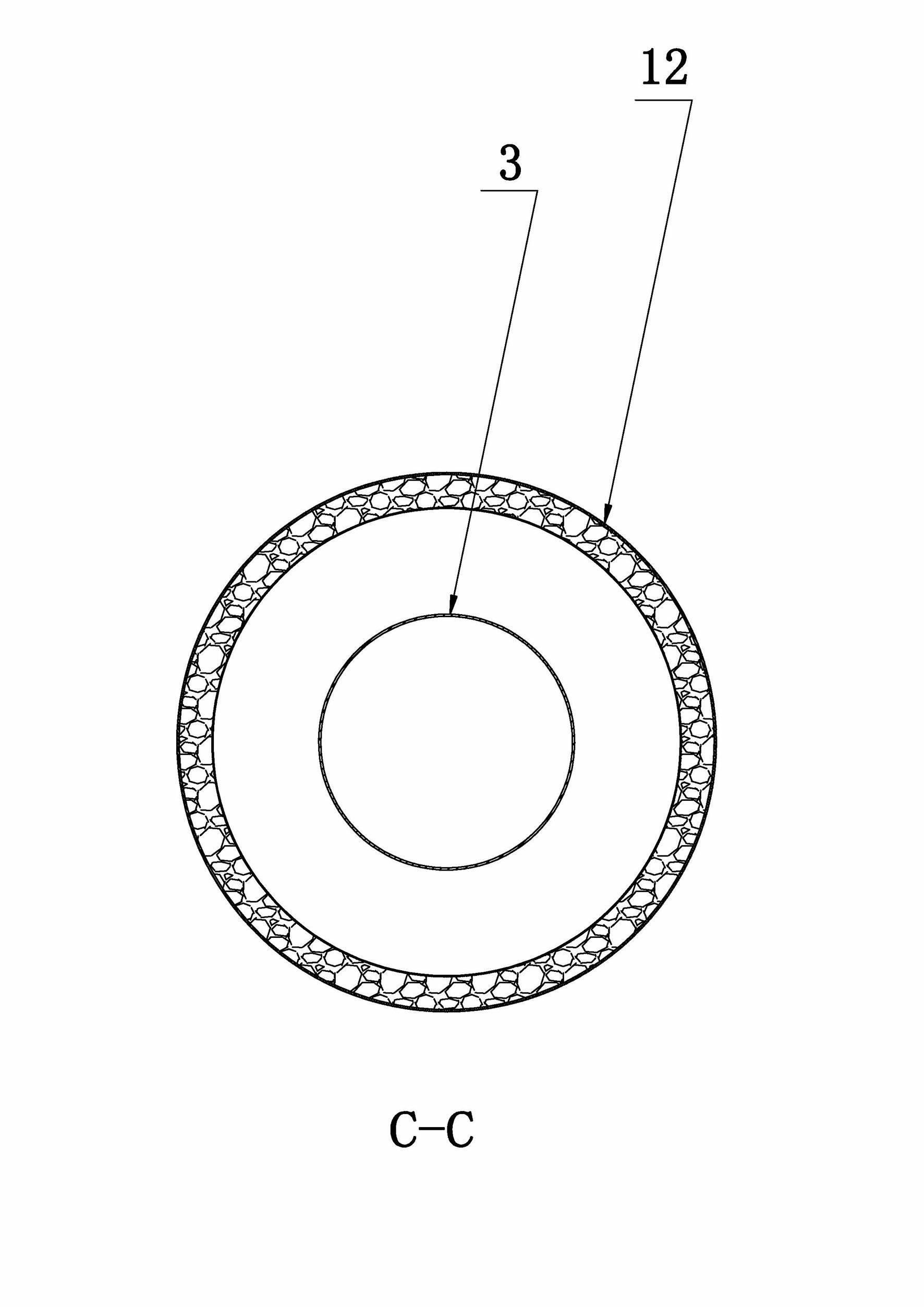

[0032] An impedance composite exhaust muffler of this embodiment is as follows: figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a resistive muffler and a resistive muffler, the resistive muffler is connected to the resistive muffler, and a third fixing ring 1 is arranged between the resistive muffler and the resistive muffler; the resistive muffler consists of the first The small head 2, the resonance tube 3, the second small head 4, the first fixed ring 5 and the second fixed ring 6, the first small head 2 includes a head with a large inner diameter and a head with a small inner diameter, and the second small head 4 includes an inner diameter The big end and the small inner diameter end, the first small head 2 with the small inner diameter and the second small head 4 with the small inner diameter are respectively the same as the inner diameter of the resonance tube 3, and the first small head 2 with the smaller inner diameter is connected to...

Embodiment 2

[0040] An impedance composite exhaust muffler, the difference between this embodiment and Embodiment 1 is that it is also provided with a muffler shell 12, a resonance tube 3, a second small head 4, an inner liner pipe 7 and a third small head 11 are placed inside the muffler shell 12. The provided muffler shell 12 can play the role of modifying the appearance, strengthening the anti-vibration ability and better fixing other components of the whole impedance composite exhaust muffler.

[0041] As a preferred embodiment, a first end panel 13 and a second end panel 14 are also provided, the first end panel 13 is fixed on one end of the muffler housing 12, and the second end panel 14 is fixed on the end of the muffler housing 12. the other end. The provided first end panel 13 and second end panel 14 prevent air flow and sound waves from entering the gap between the muffler casing 12 and the resistant muffler pipe, and can also play a role of strengthening and fixing.

[0042] A...

Embodiment 3

[0046] An impedance composite exhaust muffler, the difference between this embodiment and Embodiment 1 is that there are two or more than two sound-absorbing block shells 8, and correspondingly, it is made of ultra-fine glass fiber and high-temperature rock wool. There are two or more sound-absorbing blocks 9 of fireproof materials. In this embodiment, the preferred solution is: there are six sound-absorbing block shells 8, and correspondingly, there are six sound-absorbing blocks 9 made of porous fireproof material made of ultra-fine glass fiber and high-temperature rock wool. Six sound-absorbing blocks 9 made of ultra-fine glass fiber and high-temperature rock wool porous fireproof material are vertically arranged from top to bottom inside the liner pipe 7, which can enhance the sound-absorbing effect and ensure smooth exhaust.

[0047] The resistive muffler is also provided with an air outlet pipe 17, and one end surface of the air outlet pipe 17 is connected to an end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com