Engine magneto-rheological hydraulic mount method based on circumferential and radial flowing mode

A technology of hydraulic suspension and flow mode, which is applied in the direction of power devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of small vibration amplitude of the engine, difficulty in liquid injection, and easy generation of air bubbles, etc., to achieve magnetic circuit magnetic flux leakage weakening, Increase the adjustable range and the effect of smooth exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

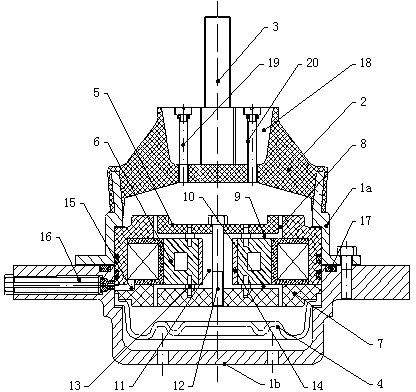

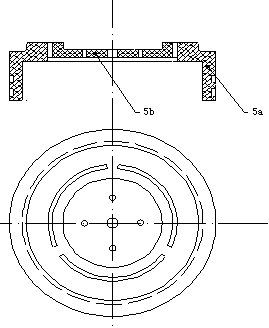

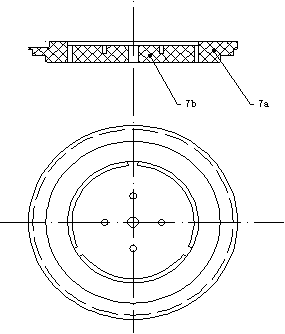

[0024] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-4 Shown: The engine magneto-rheological hydraulic mount based on the circumferential radial flow mode of the present invention includes a shell with an open top, a rubber main spring 2 arranged and blocked at the top opening of the shell, and a connection through the rubber main spring The rod 3 and the rubber bottom film 4 arranged at the inner bottom of the casing, the casing includes an upper casing 1a and a lower casing 1b connected by bolts, and the upper casing and the lower casing are both made of magnetic isolation aluminum alloy material A closed cavity filled with magneto-rheological fluid is formed between the rubber main spring and the rubber bottom film, and a magnetic core assembly is arranged in the cavity, and the magnetic core assembly includes an upper magnet from top to bottom. The core 5, the flowing coil seat 6 and the lower magnetic core 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com