Sandstone separator for directly separating mixed sandstone according to different granule diameters

A technology of sand and gravel separator and mixture, applied in the field of sand and gravel separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

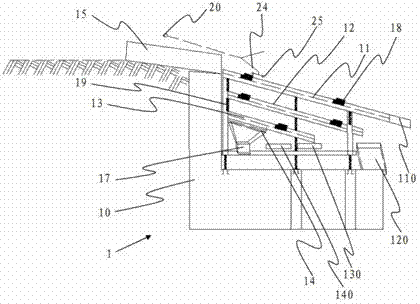

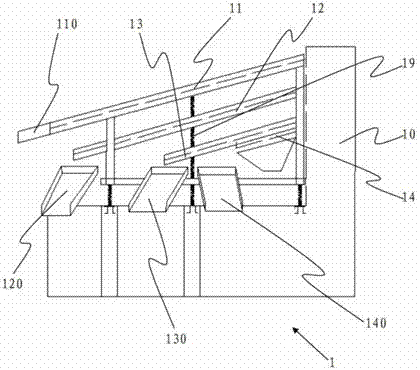

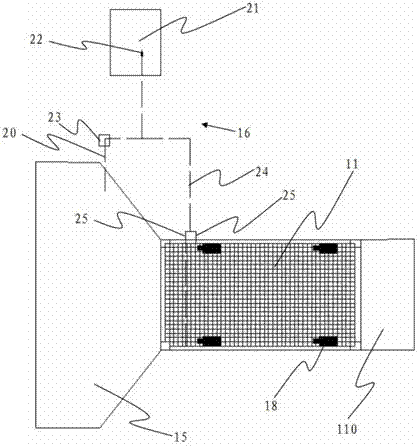

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] see first figure 1 and figure 2 As shown, the fully graded sand and gravel separator 1 of the present invention includes a frame body 10, and a first screen cloth 11, a second screen cloth 12, a first screen cloth 11, a second screen cloth 12, and a The third sieve 13 and a fourth sieve 14, the first, second, third and fourth sieves are respectively composed of a shaped steel frame and steel mesh sheets stretched in the shaped steel frame. The lower ends of the first, second, third and fourth screens are respectively erected with a discharge port, wherein the first discharge port 110 of the first screen 11 extends downward along the inclined direction of the first screen 11, The second discharge port 120, the third discharge port 130

[0019] And the fourth outlet 140 is staggered from the first screen 11 and extends to bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com