Cleaning and impurity removing device for recycling construction waste

A construction waste, cleaning and impurity removal technology, applied in the field of construction machinery, can solve the problems of excessive mud content, difficult to remove mud, and low utilization value, so as to improve resource utilization, improve aggregate quality, and reduce mud content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

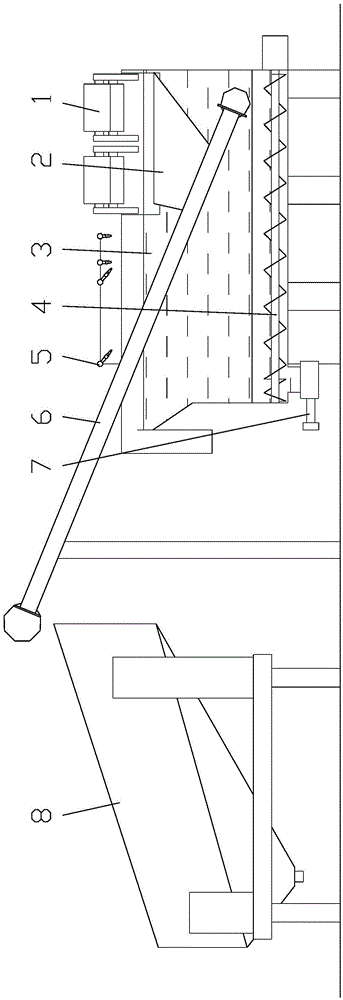

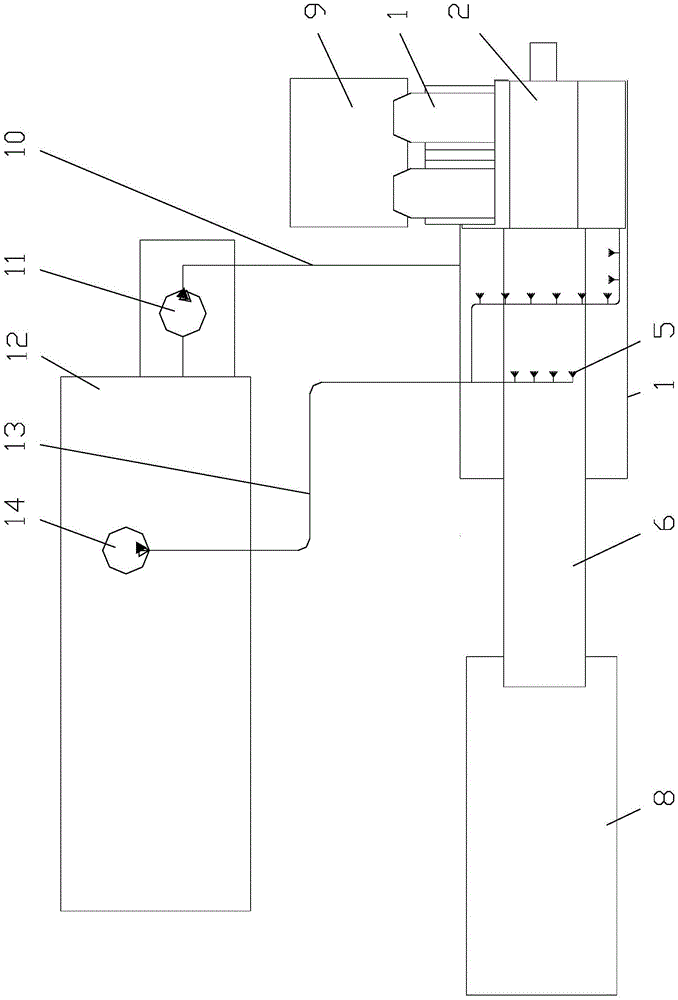

[0009] Such as figure 1 , 2 As shown, there is the low end of the belt conveyor 6 in the water tank 3, there is an aggregate dewatering screen 8 below the high end of the belt conveyor 6, and there are a hopper 2 and a nozzle group 5 above the low end of the belt conveyor 6, and the water tank One side of 3 is fixed with a sundry collection device 1, and there is a light matter dewatering screen 9 under the outlet of the sundry collection device 1, and the high-pressure nozzle group 5 is aimed at the material on the belt conveyor 6.

[0010] The water tank 3 communicates with the water recycling system 12 through the return pipe 10 and the return pump 11 , and the nozzle group 5 communicates with the water recycling system 12 through the outlet pipe 13 and the outlet pump 14 .

[0011] The bottom of the water tank 3 is fixed with a silt conveyor 4, and one end of the silt conveyor 4 is fixed with a reduction motor and an automatic valve 7. Realize automatic timing output of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com