Ceramsite filter material for aerated biological filter and preparation method thereof

A technology of biological aerated filter and ceramsite filter material, applied in ceramic products, applications, household appliances, etc., can solve the problems of reducing the use of soil resources, etc., to achieve small mud content, reduce pollution, and low soluble rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

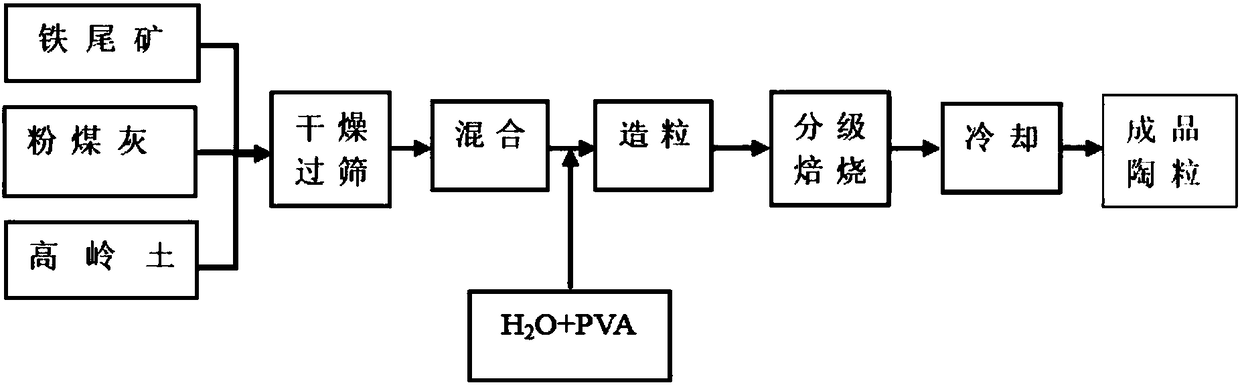

[0044] refer to figure 1 , a kind of preparation method of ceramsite filter material for biological aerated filter, it comprises the following steps:

[0045] Step 1: iron tailings, fly ash, bonding agent are mixed according to the proportion mentioned in the biological aerated filter with ceramsite filter material;

[0046] Step 2: Add deionized water and a pore-forming agent to the uniformly mixed solid raw material, and stir again to obtain ceramsite raw material;

[0047] Step 3: Make the ceramsite raw material into raw material balls;

[0048] Step 4: Carry out graded roasting to raw meal ball;

[0049] Step 5: The finished ceramsite is obtained after the ceramsite roasted at high temperature is cooled.

[0050] In step 1, before the raw materials are mixed, it also includes pretreatment of the iron tailings and fly ash. The pretreatment process includes: placing the iron tailings raw materials and the fly ash raw materials in a drying box respectively, at 105 ° C Dry...

Embodiment 1

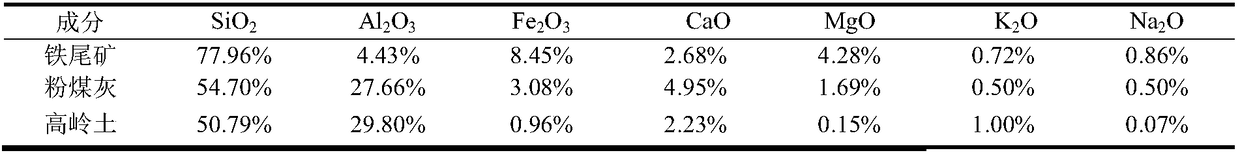

[0060] (1) Take the ceramsite raw material, dry it in a drying oven at 105°C for 3 hours, grind it after dehydration, sieve through a 150-mesh sieve, weigh 50% of iron tailings and 40% of fly ash according to the mass ratio, Kaolin 10%, total mass 1kg, mix well.

[0061] (2) Get the raw material in the step (1) and add the deionized water and the polyvinyl alcohol of 0.2 and 2ml of liquid / solid mass ratio, after mixing, put into the cement slurry mixer and mix evenly to obtain ceramsite raw meal.

[0062] (3) Take the ceramsite raw meal in step (2) and put it into a sugar coating machine to roll round pellets for 15 minutes to obtain 4-7 mm raw meal balls with uniform particle size.

[0063] (4) Take the raw material balls in step (3) and put them into a resistance furnace, keep warm at 500°C for 30 minutes, heat up at a rate of 10°C / min, and heat up to a roasting temperature of 1100°C for 5 minutes.

[0064] (5) Cool the ceramsite after high-temperature sintering with the fu...

Embodiment 2

[0067] (1) Take the ceramsite raw materials, dry them in a drying oven at 110°C for 2 hours, grind them after dehydration, and sieve through a 150-mesh sieve. Take by weight 60% of iron tailings, 30% of fly ash, 10% of kaolin, total mass 1kg, and mix.

[0068] (2) get the raw material in the step (1) and add liquid / solid mass ratio and be the deionized water of 0.3 and the polyvinyl alcohol of 1.5ml, put into the cement paste mixer after mixing evenly and mix homogeneously, obtain ceramsite raw meal.

[0069] (3) Take the ceramsite raw meal in step (2) and put it into a sugar coating machine to roll round pellets for 15 minutes to obtain 4-7 mm raw meal balls with uniform particle size.

[0070] (4) Take the raw material balls in step (3) and put them into a resistance furnace, keep warm at 400°C for 40 minutes, heat up at a rate of 10°C / min, and heat up to a roasting temperature of 1060°C for 10 minutes.

[0071] (5) Air-cool the ceramsite after high-temperature sintering to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com