Mineral separation method for recycling wolframite from tailing

A mineral processing method and wolframite technology, which is applied in the mineral processing field of wolframite recovery, can solve the problems of low comprehensive recovery rate of tungsten ore, small processing capacity, and large dosage of chemicals, so as to improve the separation index, increase the selected grade, The effect of reducing the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

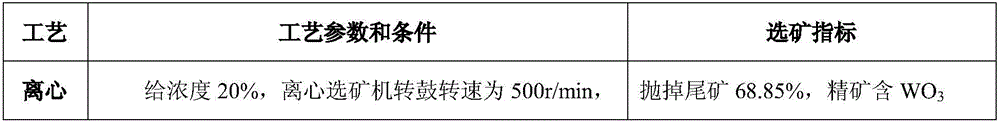

[0029] WO contained in black tungsten tailings in Ganzhou, Jiangxi 3 0.085%, -0.074mm in the tailings accounted for 78%, containing wolframite, chalcopyrite, pyrite, mica, quartz, etc. Iron - high gradient magnetic separation - shaker gravity separation - black tungsten flotation" process, can obtain WO containing 3 52.23%, wolframite concentrate with a recovery rate of 55.30%, the results of Example 1 are shown in Table 1, and the process conditions and parameters are shown in Table 2.

[0030] The beneficiation result of table 1 embodiment 1

[0031] name Yield grade Recovery rate Centrifugal Gravity Tailings 68.84 0.032 25.92 Sulfide ore flotation concentrate 8.83 0.038 3.95 Magnetic separation concentrate 1.88 0.029 0.64 High gradient magnetic separation tailings 15.98 0.041 7.71 Wolfram flotation tailings 4.38 0.125 6.48 wolframite concentrate 0.09 52.23 55.30 raw ore 100.00 0.085 100.00

[00...

Embodiment 2

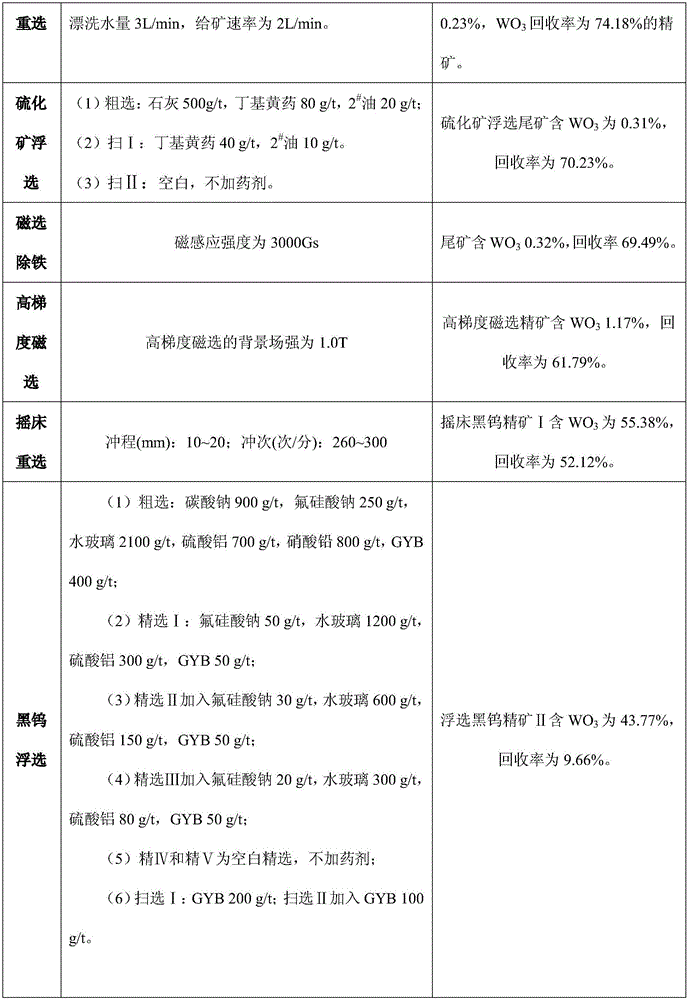

[0036] WO contained in a black tungsten tailings in Fujian 3 0.095%, -0.074mm in the tailings accounts for 81%. The main minerals in the tailings are wolframite, magnetite, chalcopyrite, pyrite, molybdenite, calcite, mica, quartz, etc., using "centrifugal rich Integrating tailings - sulfide ore flotation - magnetic separation iron removal - high gradient magnetic separation - shaker gravity separation - black tungsten flotation" process, can obtain WO-containing 3 53.16%, wolframite concentrate with a recovery rate of 55.96%, the results of Example 2 are shown in Table 3, and the process conditions and parameters are shown in Table 4.

[0037] The beneficiation result of table 3 embodiment 2

[0038] name Yield grade Recovery rate Centrifugal Gravity Tailings 67.82 0.033 23.56 Sulfide ore flotation concentrate 8.86 0.045 4.20 Magnetic separation concentrate 2.03 0.048 1.03 High gradient magnetic separation tailings 16.51 0.051 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com